Installation (cont’d)

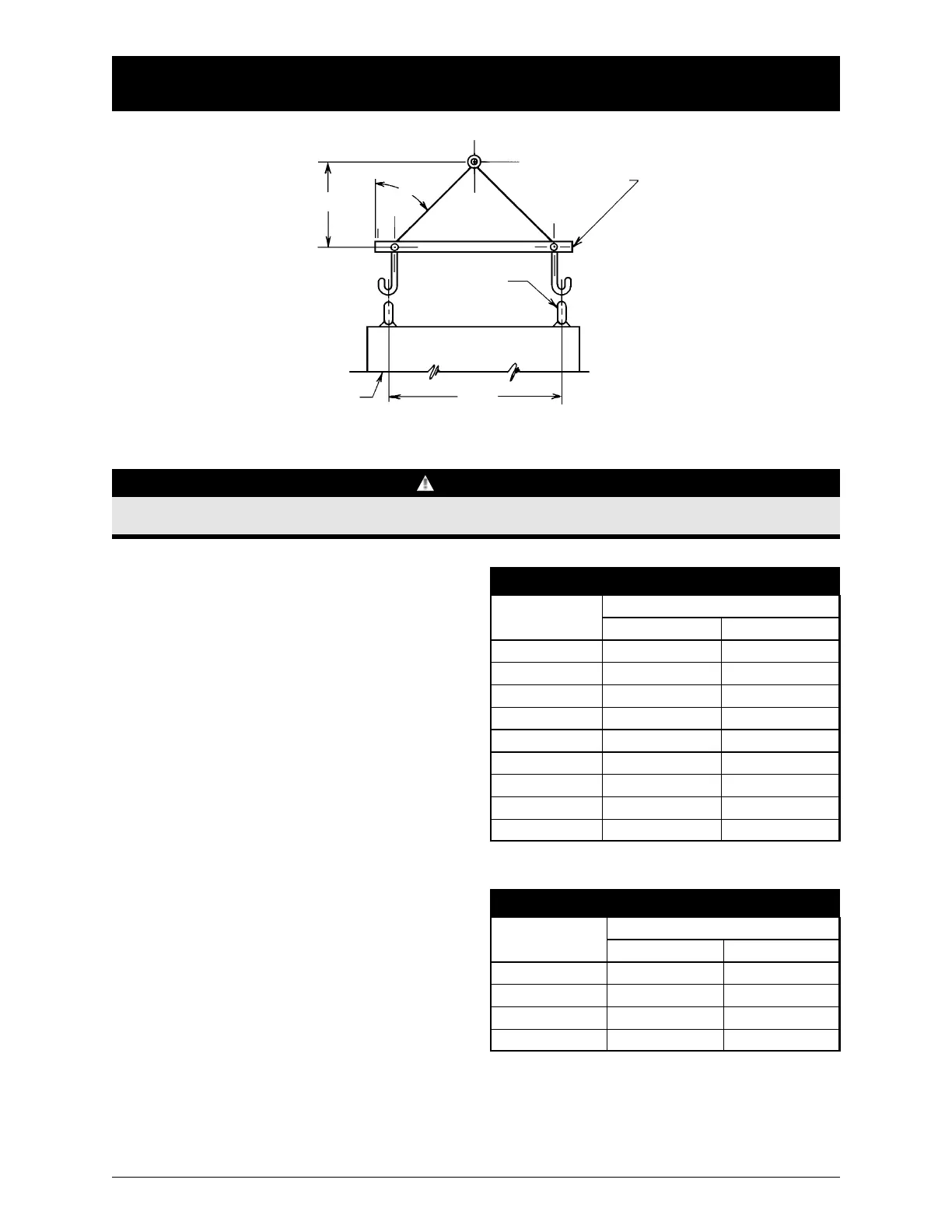

D

CABINET

LIFTING EYES

SPREADER BAR

H

45°

Figure 1

NOTICE

When lifting the switch using a spreader bar, height H must be equal to half of distance D.

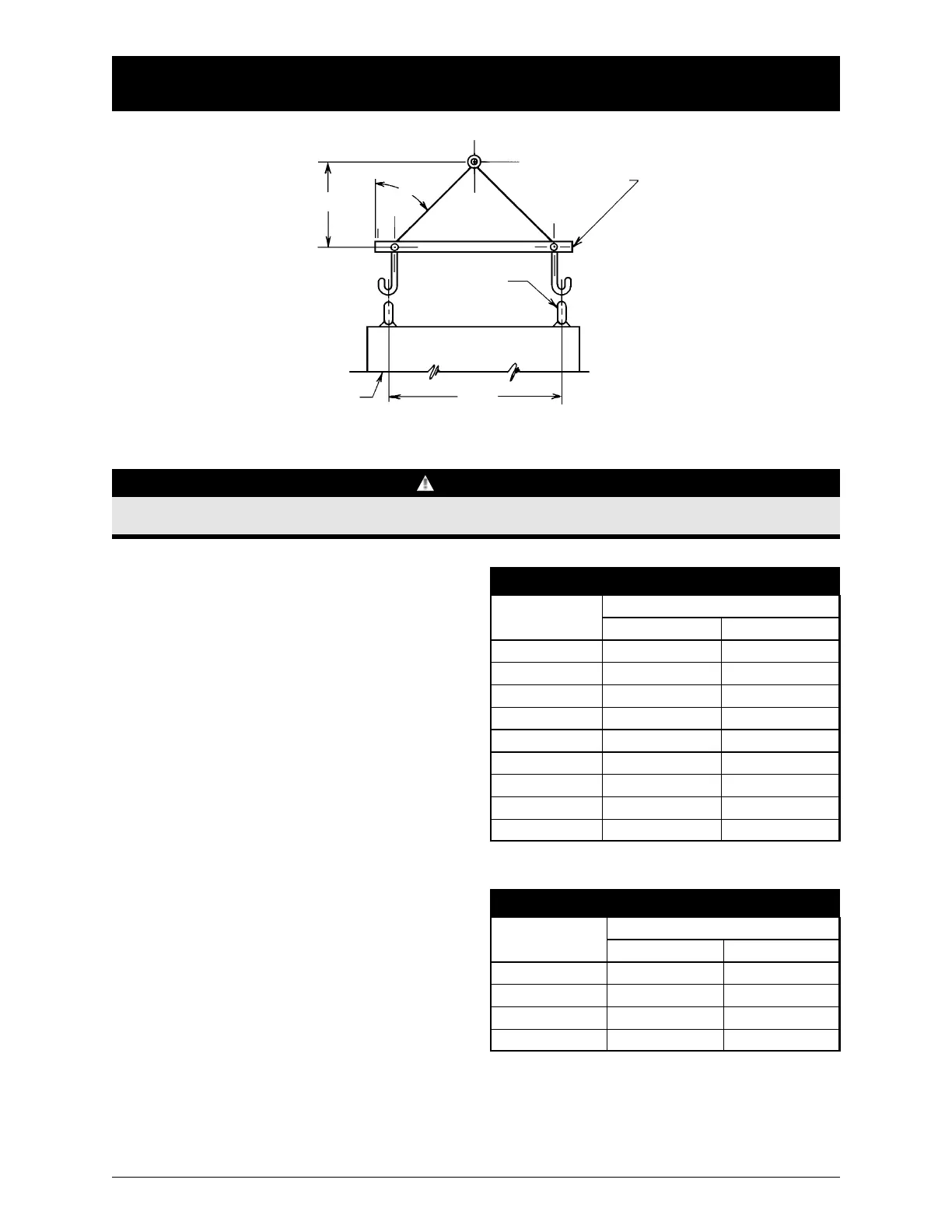

Power Connections

Zenith transfer switches are supplied with

UL listed solderless screw type terminals

as standard for the Normal, Emergency and

Load power connections. Table 1 lists the

number and sizes of cable lugs supplied

as standard for each switch amp rating.

Connect the Normal, Emergency, and Load

conductors to the clearly marked terminals

on the transfer switch. R

emove surface

oxides from cables by cleaning with a wire

brush. Verify that all connections are cor

-

rect before tightening the lugs. All cable

lug connections must be tightened to the

proper torque values as shown in T

able 2.

Do not run cables or wiring behind front-

connected transfer switches.

In cases where the Normal, Emergency and

Load connections are made to a rear con-

nected bus bar, a compression washer, flat

washer, and a minimum grade 5 bolt must

be used and torqued to the values in T

able 3.

Tightening Torque for Lugs

Socket Size

Across Flats

Torque

Lb. - In. Lb. - Ft.

1/8 45 4

5/32 100 8

3/16 120 10

7/32 150 12

1/4 200 17

5/16 275 23

3/8 375 31

1/2 500 42

9/16 600 50

Tightening Torque for Bus Bars

Bolt Size

Torque Bolt (Grade 5)

Lb. - In. Lb. - Ft.

1/4-20 72 6

5/16-18 132 11

3/8-16 300 25

1/2-13 720 60

Table 2

Table 3

Zenith Controls, Inc.

ZTSH Operation and Maintenance Manual (43R-1000)

3

Loading...

Loading...