7

Notes ball valves

■ Mount ball valves up- and downstream of the

meter.

■ Mount a ball valve with bore M10x1 for direct

sensors in the supply. This is required for the

installation of the supply sensor

■ For symmetrical temperature sensor installa-

tion, mount an identical ball valve in the return.

This one is used for mounting the return sensor.

Mounting heating- / cooling energy meter

■ Flush the system thoroughly before installing

the heating-/cooling energy meter.

■ Close valves and release pressure.

■ Dismount the existing ow sensor or meter blank.

■ Use only new and awless sealing material

and check the seal face for damage.

■ Install the new ow sensor according to the

correct ow direction and installation position.

■ Turn heat computer to desired reading position.

Information: The best measuring results can be

achieved by mounting with horizontal diallevel.

Combi-devices are, for example, used in tight

installation points without room for the calculator

on the ow sensor or when the calculator is dif-

cult to read. Therefore the device still remains

easy to read enabling optimum use of the space

available for installation of the ow meter.

Installing the temperature sensor

■ The installation of the temperature sensors

should be preferably symmetrical and direct

installation.

■ Do not remove the return sensor if already

mounted in the VMU.This is also valid for all

the safety seals which are mounted on the de-

vice as standard.

■ Sensors are colour-coded (red = supply, blue

= return).

■ The connecting cables may not be buckled, ex-

tended or shortened.

■ The seal at the sensor installation point on the

measuring capsule may not be damaged.

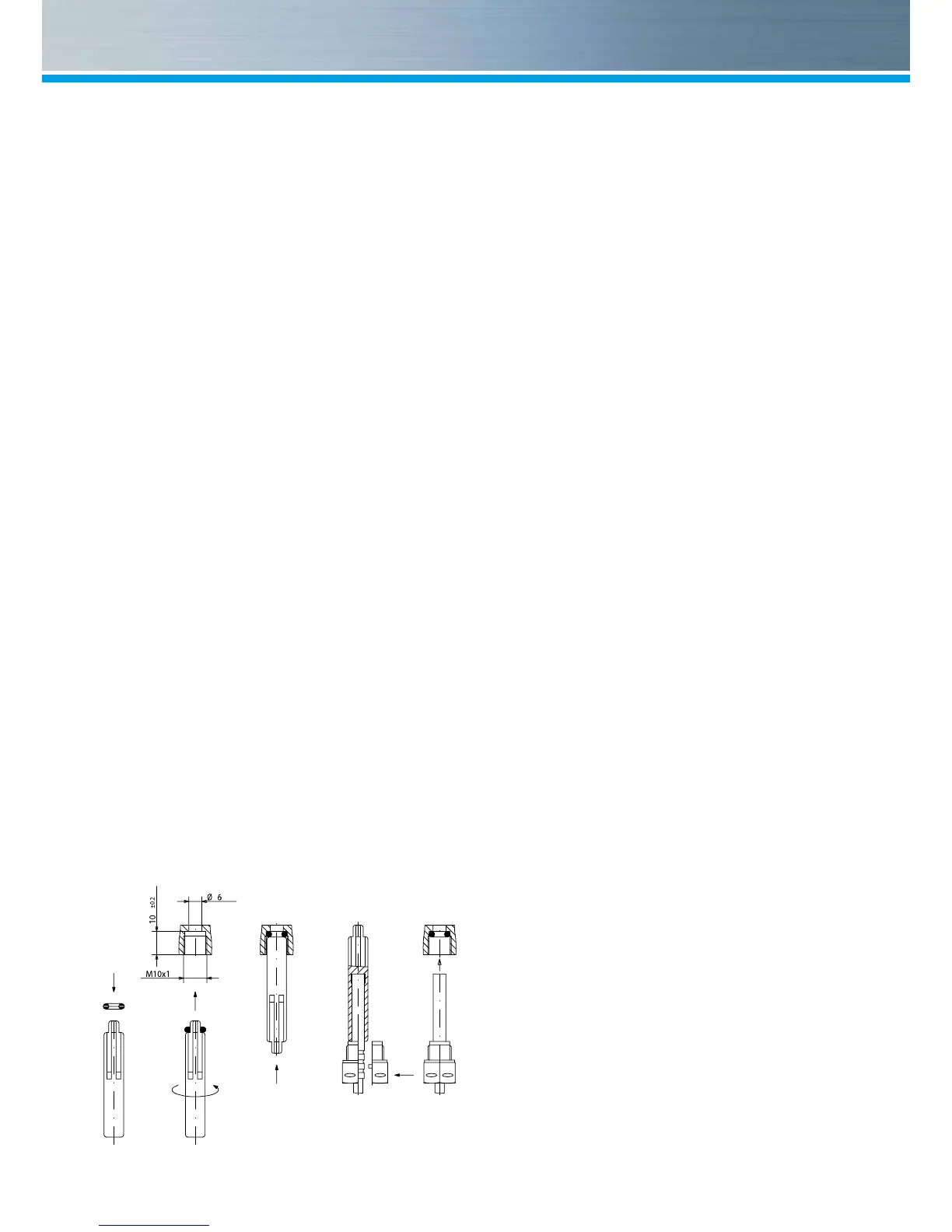

■ Remove locking screw and seal at the ball

valve completely, if existing.

■ Attach the O-ring to the installation aid (the 2nd

O-ring is only a spare O-ring).

■ Using the installation aid, insert the O-ring into

the installation point according to DIN EN 1434

with a slight circular motion.

■ Using the other end of the installation aid bring

the O-ring into the correct position.

■ Insert the 2 halves of the plastic connector into

the sensor’s three notches (crimps) and press

them together.

■ Use the installation aid as positioning aid.

■ Insert the temperature sensor into the installa-

tion point and screw it in tightly until the dead

stop of the seal on the 12-point is reached

(mounting torque 3-5 Nm).

■ The sensor optional integrated in the VMT has

to be secured

■ Secure the sensor after installation against

unauthorised removal with appropriate sealing

(available as a sealing set).

Montage DF- Adapter

Loading...

Loading...