4

© Copyright 2013 Zoeller Co. All rights reserved.

OR

HYDRAULIC CEMENT

LEVEL WITH

OR SIMILAR MATERIAL

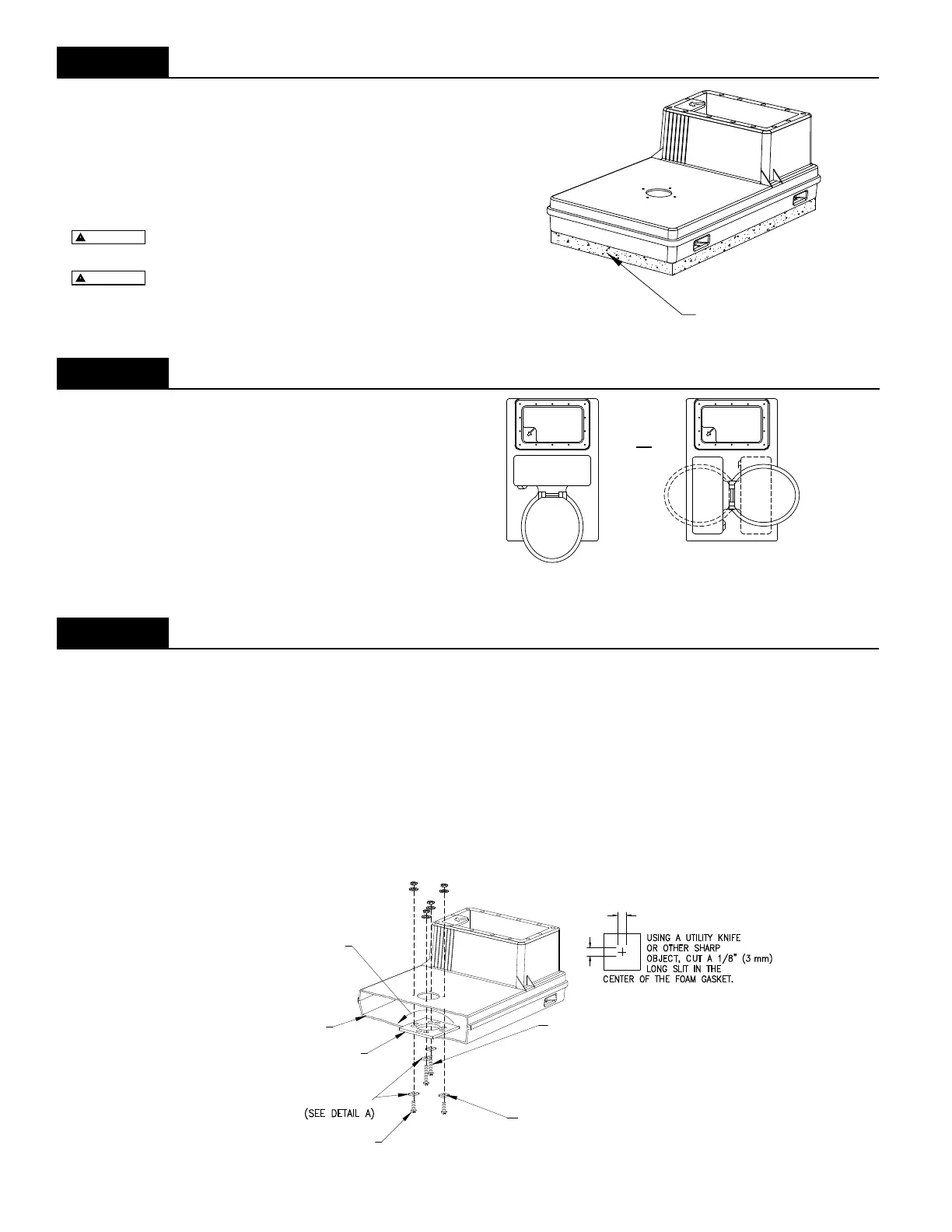

STEP 1 LOCATION SELECTION AND LEVELING OF TANK

Figure 1.1

NOTE: If a built in installation is to be used, locate pump chamber

in an area that will allow access to the pump & switch.

1.1) Select a location which is readily accessible to the existing

discharge and vent lines.

1.2) Level tank to within

1

/

8

” for length and width. Use hydraulic

cement or similar material for leveling. Refer to Figure 1.1.

Do not use wooden shims to level tank!

Ensure that nails, screws or other sharp objects do

not puncture tank!

STEP 2 ORIENTATION OF TOILET ON TANK

2.1) Determine the orientation of toilet on tank. This

determines the location of the long bolts in STEP 3 of

the installation. Refer to Figure 2.1 or Figure 2.2.

NOTE: Model 101 comes preassembled in the forward

installation position. If a side installation is desired, bolts must

rst be removed and then reinstalled per STEP 3. Also, if

subooring is being installed, the 2” bolts must be removed

and replaced with 3” bolts per STEP 3.

Side Installation

Figure 2.2

Forward Installation

Figure 2.1

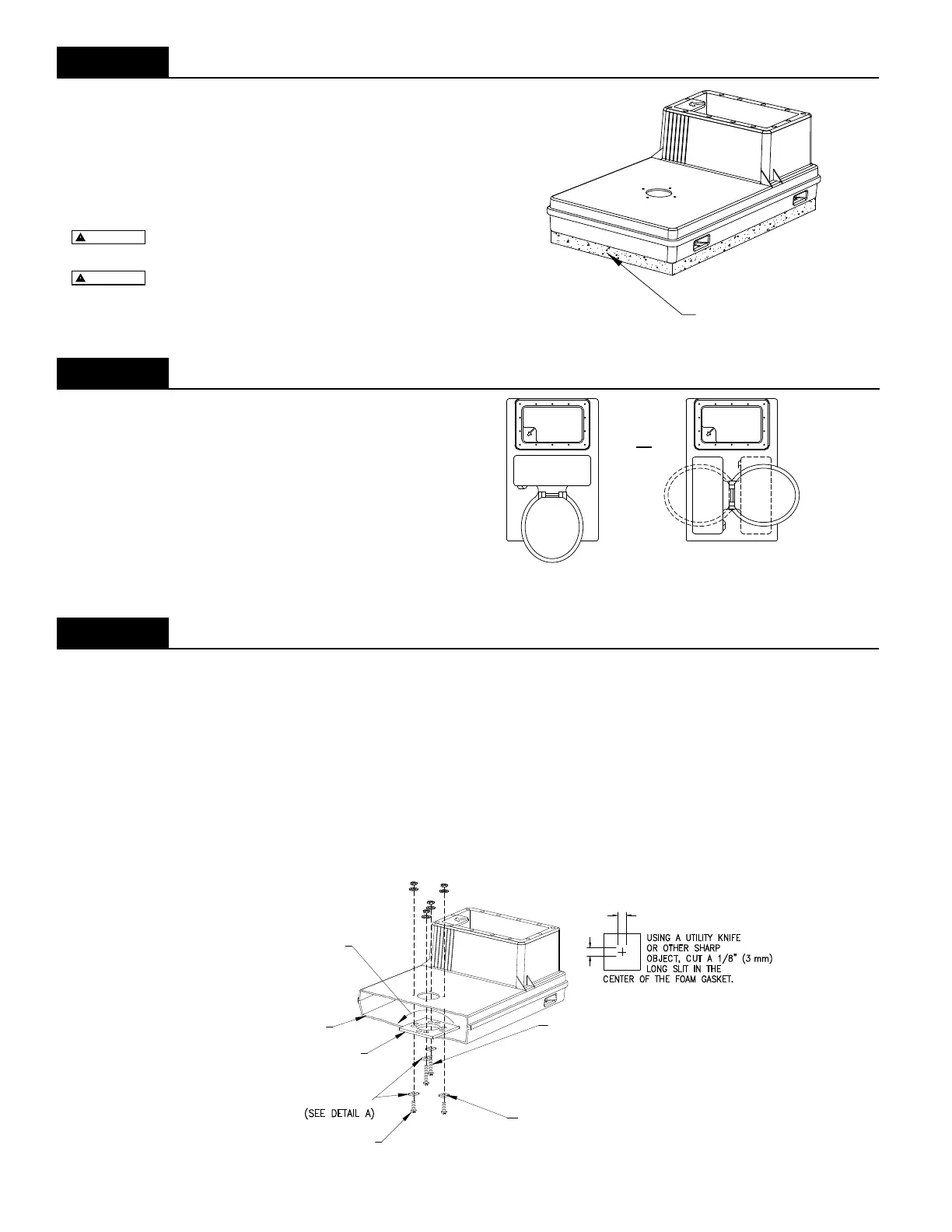

STEP 3 INSTALLATION OF THE CAST IRON SUPPORT

Model 101: If the bolts are correct for your desired installation, skip to STEP 6.

NOTE: If subooring is being installed over the tank, use the ¼” - 20 X 3” long bolts supplied with the oor

ange extender kit, otherwise use the ¼” - 20 X 2” long bolts. The longer bolts account for the thickness of

the subooring when mounting toilet.

3.1) Drill the 4 preselected holes, located around the toilet opening, with a

9

/

32

” drill bit. (Models 100 & 102 only)

3.2) Modify the 4 foam gaskets, supplied with the wax ring kit, as shown in Detail “A”. (Models 100 & 102 only)

3.3) Install the cast iron plate inside the tank through the pump chamber with the at side up. Rotate the plate to rest

on tank supports. (Models 100 & 102 only)

3.4) Make certain that the 2” or 3” long toilet mounting bolts are in the correct locations to accept the toilet as deter-

mined in STEP 2. Torque screws to 25-30 in-lbs.

AND ADHERE GASKET TO UNDERSIDE

OF CAST IRON SUPPORT AT EACH

2 X (1/4-20 X 1" (25 mm))

BOLTS

HOLE LOCATION.

REMOVE PROTECTIVE BACKING

SUPPORT FLANGE

(SEE DETAIL A)

FOAM GASKETS

CAST IRON

CUT-AWAY

OF TANK

LONG SLIT IN THE

CENTER OF THE FOAM GASKET.

2 X (1/4-20 X 3" (75 mm)) BOLTS

2 X (1/4-20 X 2" (50 mm)) OR

SEE NOTE:

USING A UTILITY KNIFE

OR OTHER SHARP

OBJECT, CUT A 1/8" (3 mm)

1/8” (3 mm)

1/8” (3 mm)

ON TANK SUPPORTS

ROTATE PLATE TO REST

DETAIL “A”

SK1746

SK1747

Figure 3.1

SK1748

Loading...

Loading...