INST2018_Model350_65-250 Rev. 11/18

ZURN.COM.AU

ZURN WILKINS BACKFLOW

Double Check Valve Assembly

INSTALLATION & MAINTENANCE

MODEL 350 65-250mm

SERVICING CHECK VALVES

Aach a ratchet wrench, 17mm deep socket, and a 100mm

long extension are recommended for removing check

assemblies.

1. Close inlet and outlet shut-off valves.

2. Open No. 2, No. 3 and No. 4 test cocks to release pressure

from valve.

3. Loosen & remove the grooved coupling around the access

cover. Remove cover.

4. To service only the #1 check assembly, remove the 6 bolts,

washers and o-rings from the back of the #1 check assembly.

Separate the retainer and the seal ring from the check

assembly and proceed to step #8.

5. To service both checks or the #2 check, the #1 check assembly

must first be removed. Remove the 4 nuts and washers

retaining the #1 check assembly. Remove the #1 check

assembly from the body.

6. To remove the #2 check assembly, remove the 7 nuts,

washers and the #2 check retaining ring. Grasp the check

assembly by the stem and remove from valve.

7. Remove all 6 bolts, washers and o-rings from the check

assembly (See “Check Assembly” illustraon). Separate

retainer from check assembly to expose seal ring for inspec-

on.

8. Inspect the rubber seal ring for cuts or embedded debris. If

the reverse side of the seal ring is unused, it is possible to

invert the seal ring. This would be considered a temporary

soluon to fixing a fouled check and should be replaced with

a new seal ring as soon as possible.

9. Inspect valve cavity and seang areas. Remove any debris.

10. Reverse the above procedures to reinstall check assemblies.

Lubricate seat o-rings to hold them in place while reinstalling

seat. Place washers on studs and ghten retaining nuts

evenly.

11. Reinstall access cover and grooved coupling.

NOTE:

If any poron of the seat assembly is damaged or missing or if

the seat sealing rib is damaged in any way, do not aempt to

field repair it. Contact your local ZURN WILKINS representa-

ve for assistance.

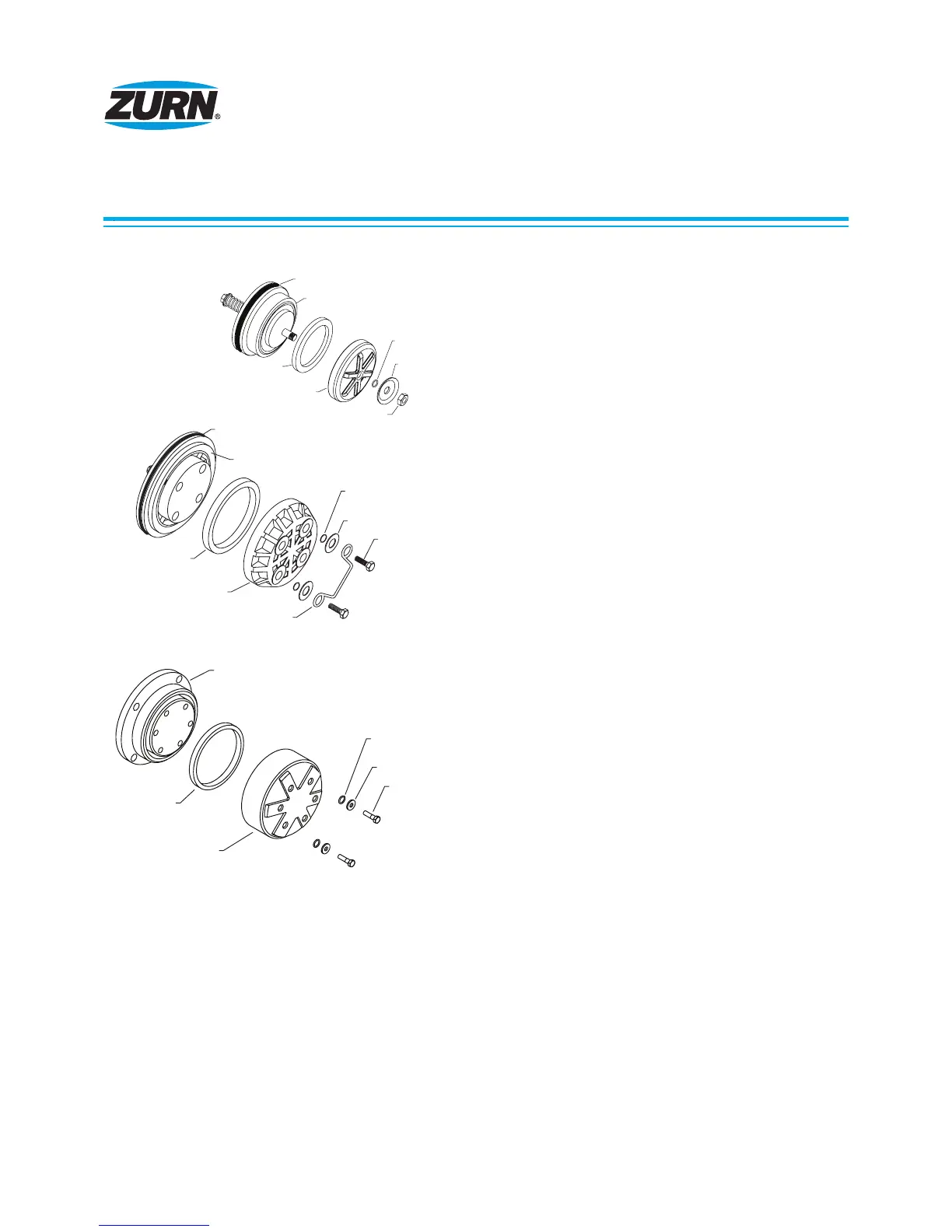

CHECK ASSEMBLY

SEAT ASSEMBLY

SEAL RING

O-RING

(BOLT)

SEAL RETAINER

WASHER

BOLT

CHECK HANDLE

O-RING (SEAT)

65 & 80mm

100 & 150mm

SEAT ASSEMBLY

SEAL RING

O-RING

SEAL RETAINER

WASHER

O-RING (SEAT)

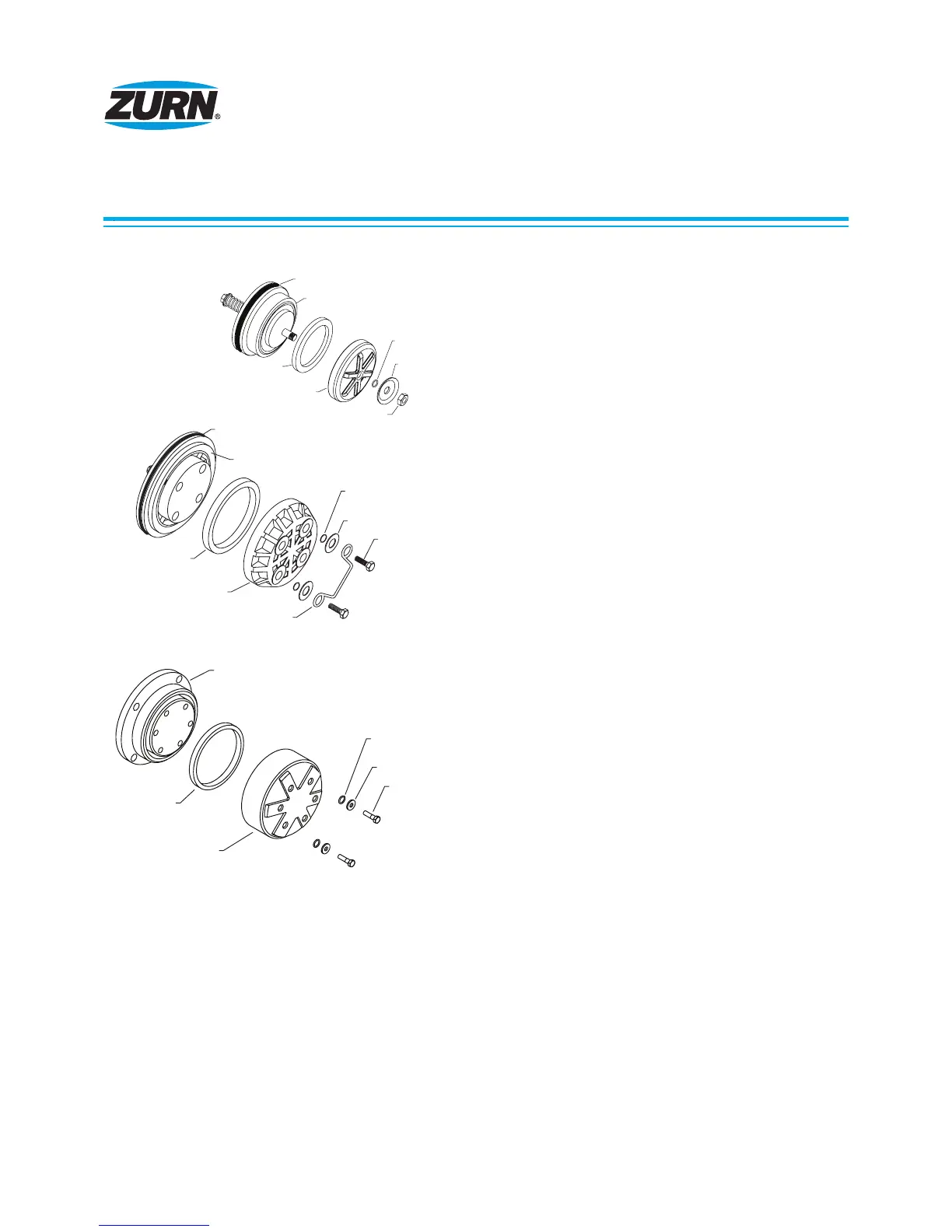

SEAT ASSEMBLY

SEAL RING

O-RING

(BOLT)

RETAINER

WASHER

BOLT

200 & 250mm

All Model 350 Double Check Valve Backflow Preventers must be

inspected and maintained by licensed personnel at least once a

year or more frequently as specified by local codes. Replace-

ment of worn or damaged parts must only be made with

genuine “ZURN WILKINS” parts.

GENERAL MAINTENANCE

1. Clean all parts thoroughly with water aer disassembly.

2. Carefully inspect rubber seal rings and o-rings for damage.

3. Test unit aer reassembly for proper operaon (refer to

“TESTING PROCEDURES”).

Loading...

Loading...