14

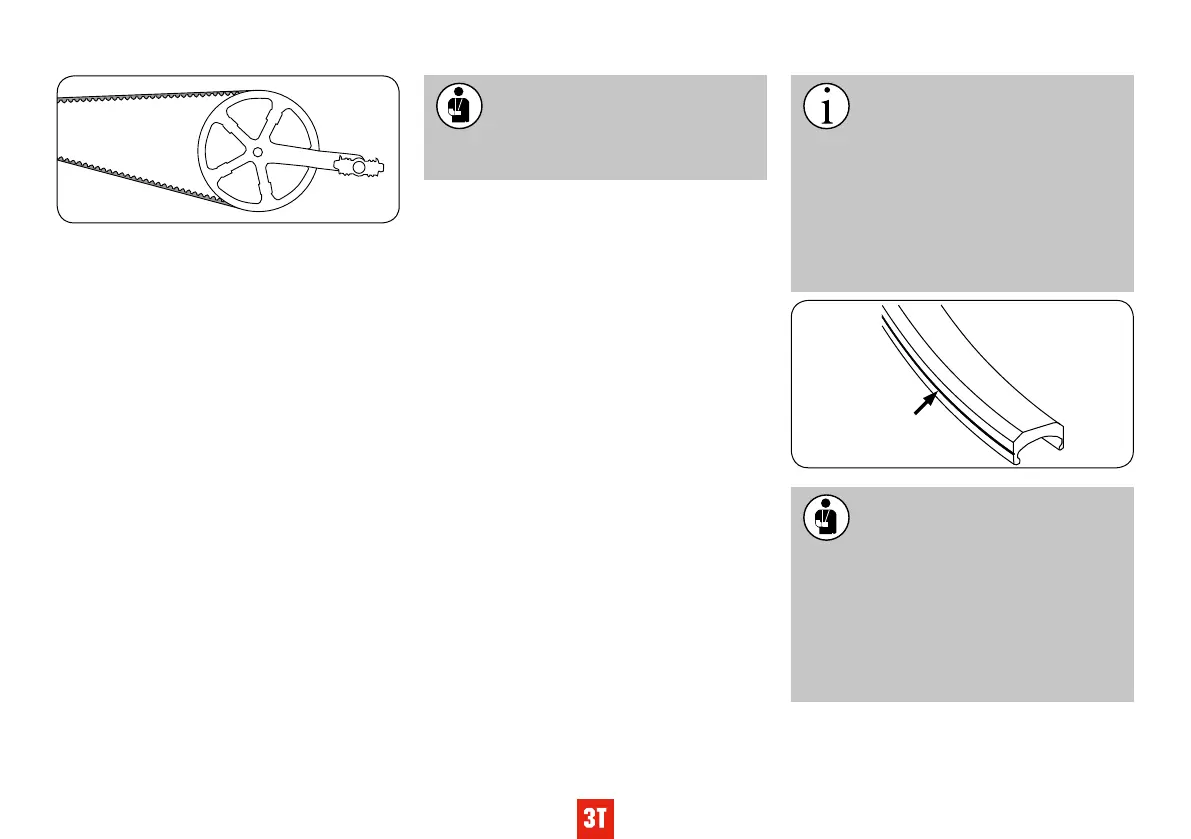

Rims are subject to a great deal of

strain and are vital to your safety on

the bike. Riding wears rims down

over time, particularly on bicycles with rim

brakes. If you notice any damage or the wear

indicators show dangerous levels of wear,

you should no longer ride with these rims.

Have them checked by a specialist retailer

and replaced if required.

Wear can weaken rims and lead to falls and

serious accidents.

Groove as a wear

indicator

Wheels

Checking the wheels

The bicycle is connected to the ground by the

wheels. The wheels are subject to a great deal of

strain through the uneven characteristics of the

ground and the weight of the rider.

Thorough checks and centring work on the

wheels are undertaken before they are shipped.

However, during the rst few kilometres of riding,

the spokes bed in.

• After the rst 100 kilometres (62 miles), the

wheels have to be checked by a specialist and

centred again if required.

• The tension of the spokes has to be checked

at regular intervals. Loose or damaged spokes

have to be replaced or centred by a specialist

retailer.

The wheels can be xed in the frame and fork in

different ways. Commonly, the wheel is attached

with an axle nut or a quick release. In addition,

there are also various thru axle connections

which are screwed in or xed with various quick

release systems. If a thru axle is tted on your

bicycle, you can get more information in the en-

closed manufacturer operating manual or on the

respective manufacturer’s website.

Modern rims (from 24") indicate when

they are worn from braking. These in-

dicators take the form of embossed

or coloured points or lines on the brake sur-

faces of the rims. When these disappear, you

are no longer permitted to use the rims. There

are also similar indicators which only appear

after a certain level of wear. At the very latest

when two pairs of brake rubbers have been

worn, it is necessary to have the rims check

by a specialist retailer.

Rims/tires

Clean the rims regularly according to the inspec-

tion plan on page 23. As part of this, you should

also check the wear indicators:

Checking the hubs

You can check the hub bearings as follows:

• Raise the wheel off the ground, lifting the bi-

cycle rst at the front and then the rear. Push

each wheel to start them turning.

• The wheel should continue to turn and then

slow evenly. If the wheel suddenly stops, the

bearing is defective. One exception is front

wheels with a hub dynamo. These display a

rather greater degree of resistance. This is

barely noticeable when cycling, but is notice-

able in this test.

• The hub bearing should not exhibit play. Pull

the wheel to the right and left in its forks or in

the chain stays to establish whether it is loose.

There should be no play noticeable.

• If the wheels can be slightly moved in their

bearings or are difcult to turn, the hub bear-

ings have to be set up by a specialist retailer.

All screw connections have to be

tightened with the correct torque. If

the torque is not correct, the screws

could break or loosen other parts (see page

26 “Torques for screwed connections”).

Loading...

Loading...