9 CONGLOMKB.COM

Please contact 1-877-333-0098 for further assistance.

Pre-Installation (continued)

Follow these guidelines when installing duct work:

- Your venting system must vent to the outdoors either horizontally through the back wall (13) or vertically through the

roof (14) (refer to Fig. 4/Fig. 5).

- Use round metal duct work with a uniform diameter of 6 in. (152 mm). The total duct run in the venting system should

be not more than 10.7 m (35 ft).

- Calculate the total effective length of the duct work by adding the equivalent lengths in the table shown (Fig. 6). For

each tting used add the length of the equivalent straight duct used in the system.

- Fasten all connections between pieces of duct with sheet metal screws and tape all joints with certied duct tape.

- If you must turn the path of the duct work using elbows, keep the number of elbows to a minimum for effective

performance and use no more than three 90° elbows. Ensure that there is a minimum of 18 in. (458 mm) of straight vent

between each elbow. Elbow as far away from the range hood’s exhaust opening as possible.

- Cap the exterior of the duct with a wall cap (15) or roof cap (16). Never use 4 in. (102 mm) laundry-type wall caps. Use

caulking to seal exterior wall or roof opening around the cap.

- The venting system must have a damper. If the roof or wall cap has a damper, do not use the damper supplied with the

range hood.

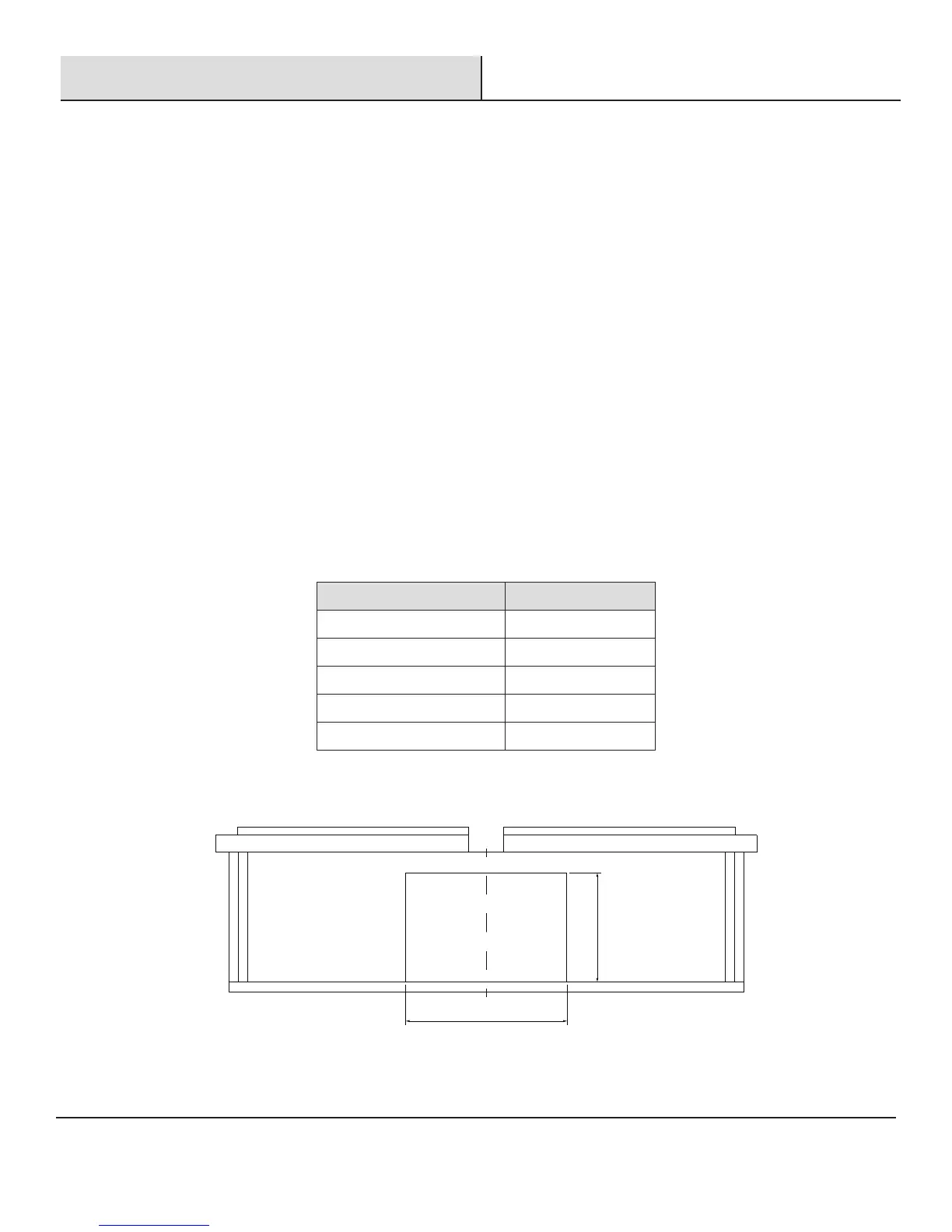

Size of the hole to be cut on the bottom of the cabinet (refer Fig. 7).

Size of motor housing that needs to be inside the cabinet (refer Fig. 2 on page 7).

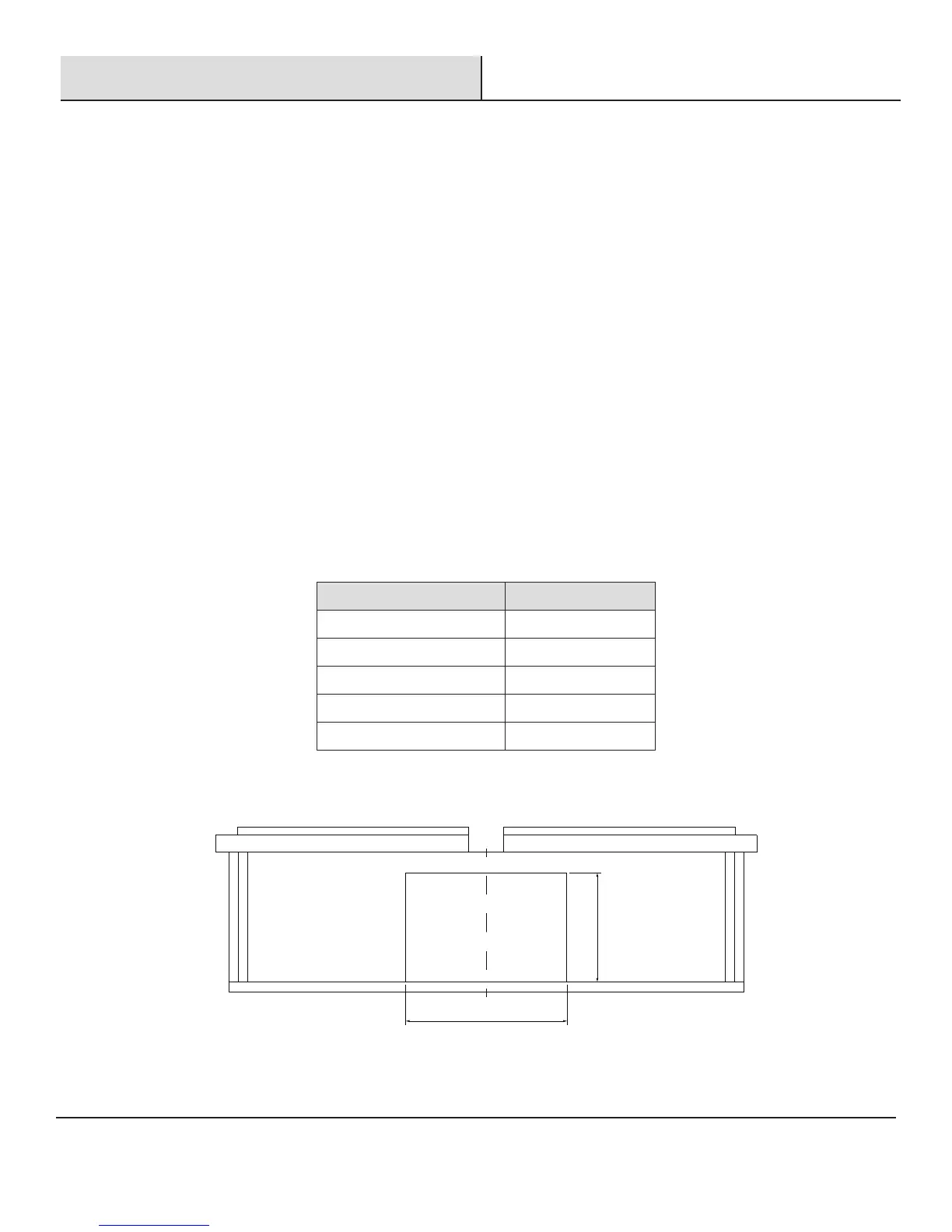

Equivalent Length Chart

Type of duct Length added

90° Elbow 5 ft (1.52 m)

90° Flat elbow 12 ft (3.66 m)

2 x 90° Elbow 10 ft (3.05 m)

9 ft (2.74 m) Straight duct 9 ft (2.74 m)

Wall cap 0 ft (0 m)

15” (380mm)

Fig. 6

Fig. 7

Loading...

Loading...