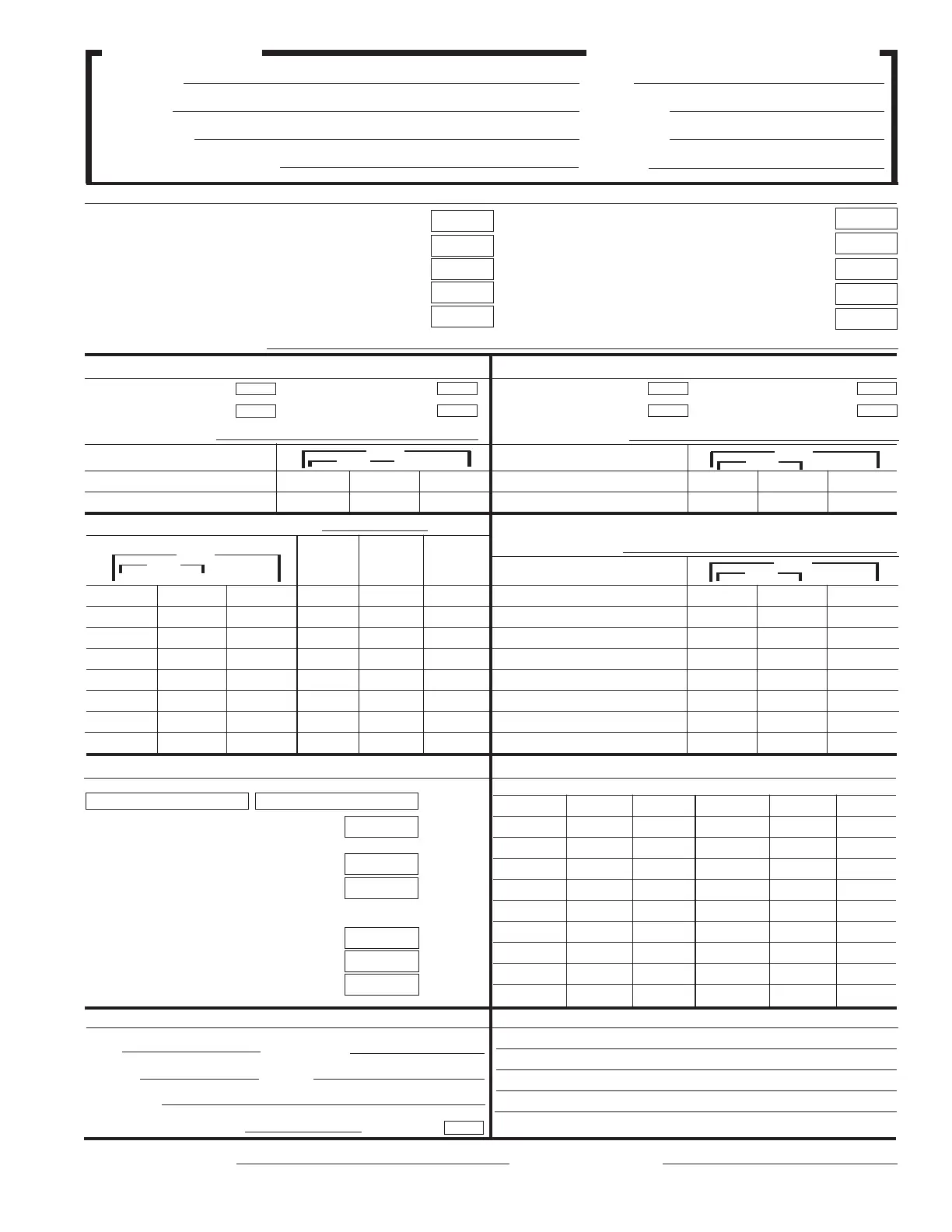

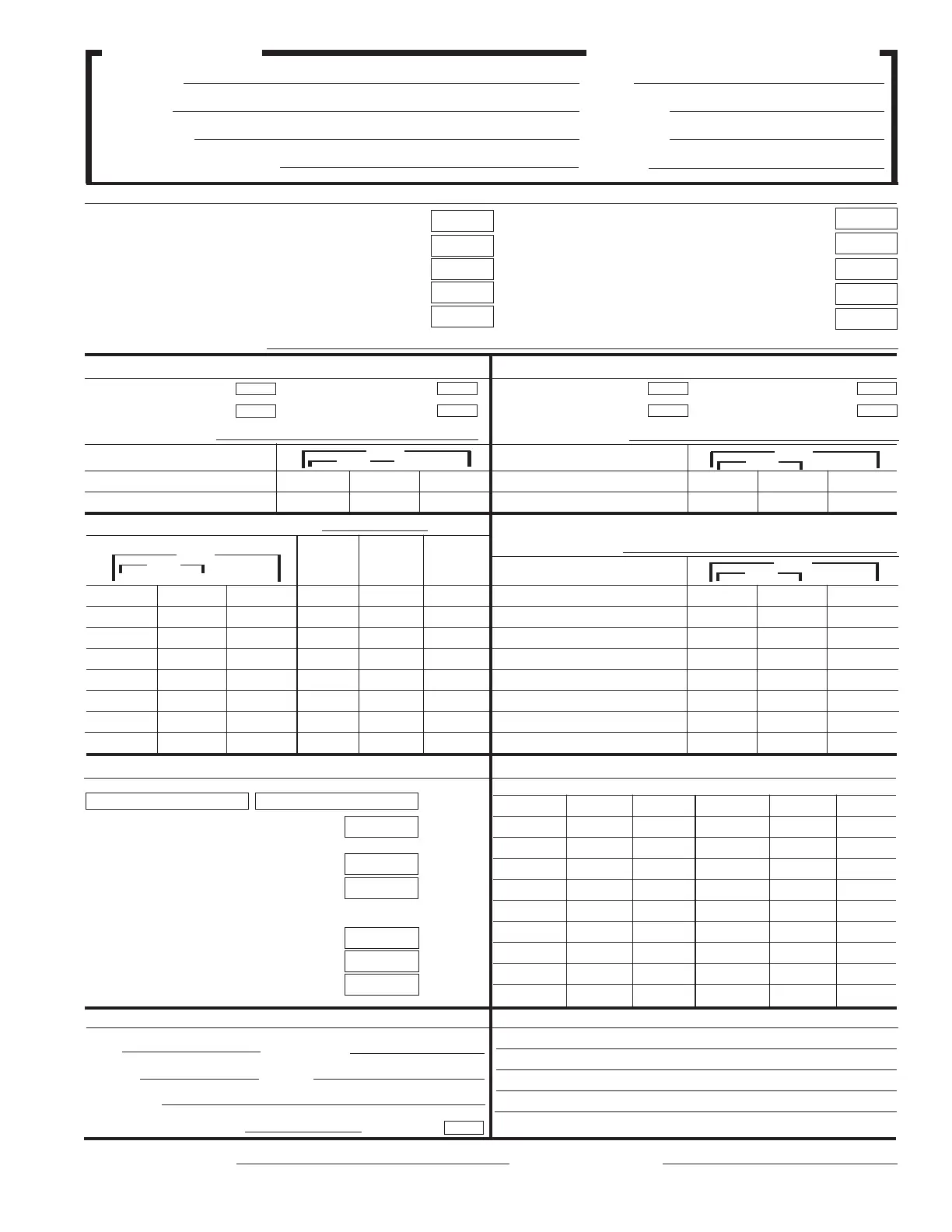

23

AAON , Inc.

JOB NAME:

ADDRESS:

CITY, STATE:

FACTORY START-UP FORM

Check & Tighten All Electrical Terminals:

Verify All Copper Tubing Is Isolated So It Doesn't Rub:

Check All Fans For Free Movement:

Inspect Unit For Damage:

Verify All Air Filters Are Installed:

START-UP CONTRACTOR:

SERIAL No:

MODEL No:

DATE:

START-UP CHECK LIST • GENERAL CHECKS

RTU No:

Verify Voltage:

Verify Transformer Tap On 208/230v Equip.:

Inspect Economizer Damper Assembly:

EVAPORATOR BLOWER ASSEMBLY POWER EXHAUST ASSEMBLY

FAN(S) ALIGNMENT: BELT(S) TENSION:

FAN(S) ALIGNMENT: BELT(S) TENSION:

1

2

1

2

3 Ø

1 Ø

MOTOR MAKE / AMPS

3 Ø

1 Ø

MOTOR MAKE / AMPS

1

2

3

4

COMP. No.& AMPS

3 Ø

1 Ø

COOLING TEST • AMB. TEMP: °F

Head

Pressure

PSIG

Crankcase

Heater

Amps

Suction

Pressure

PSIG

5

6

7

8

MOTOR MAKE & AMPS

1

2

3

4

3 Ø

1 Ø

8

5

6

7

L1 L2 L3

NAMEPLATE AMPS:

NAMEPLATE AMPS:

CHECK FAN ROTATION: VAV CONTROLS:

CHECK FAN ROTATION: AUTO AIR BALANCE:

Open Outside Air Hood (if applicable):

Tighten All Set Screws On Pulleys, Bearings & Fans:

Additional Checks and Notes:

START-UP TECHNICIAN: START-UP VERIFIED BY:

CONDENSER ASSEMBLY

NAMEPLATE AMPS:

HEATING TEST • NATURAL GAS • LP GAS HEATING TEST • ELECTRIC •

1

11

212

313

414

515

616

717

818

919

10 20

HEATER No.& AMPS

2nd STAGE HIGH FIRE: W.C.

1st STAGE LOW FIRE: W.C.

SINGLE STAGE: W.C.

MANIFOLD PRESSURE

NATURAL GAS PROPANE (L.P.)

VERIFY INLET GAS PRESSURE: W.C.

(refer to data plate)

VERIFY PILOT SPARK:

PURGE AIR FROM LINES:

MISC. CONTROLSECONOMIZER

TYPE: MOTOR TYPE:

ECON. CHG.OVER • TYPE: OPERATION:

OPERATION:

WIRING: GEARS:

Loading...

Loading...