REPLACING THE CHAMBER BLOCK

Replacing the Chamber Block

S

S

T

T

E

E

P

P

1

1

2

2

FITTING THE CHAMBER BLOCKS

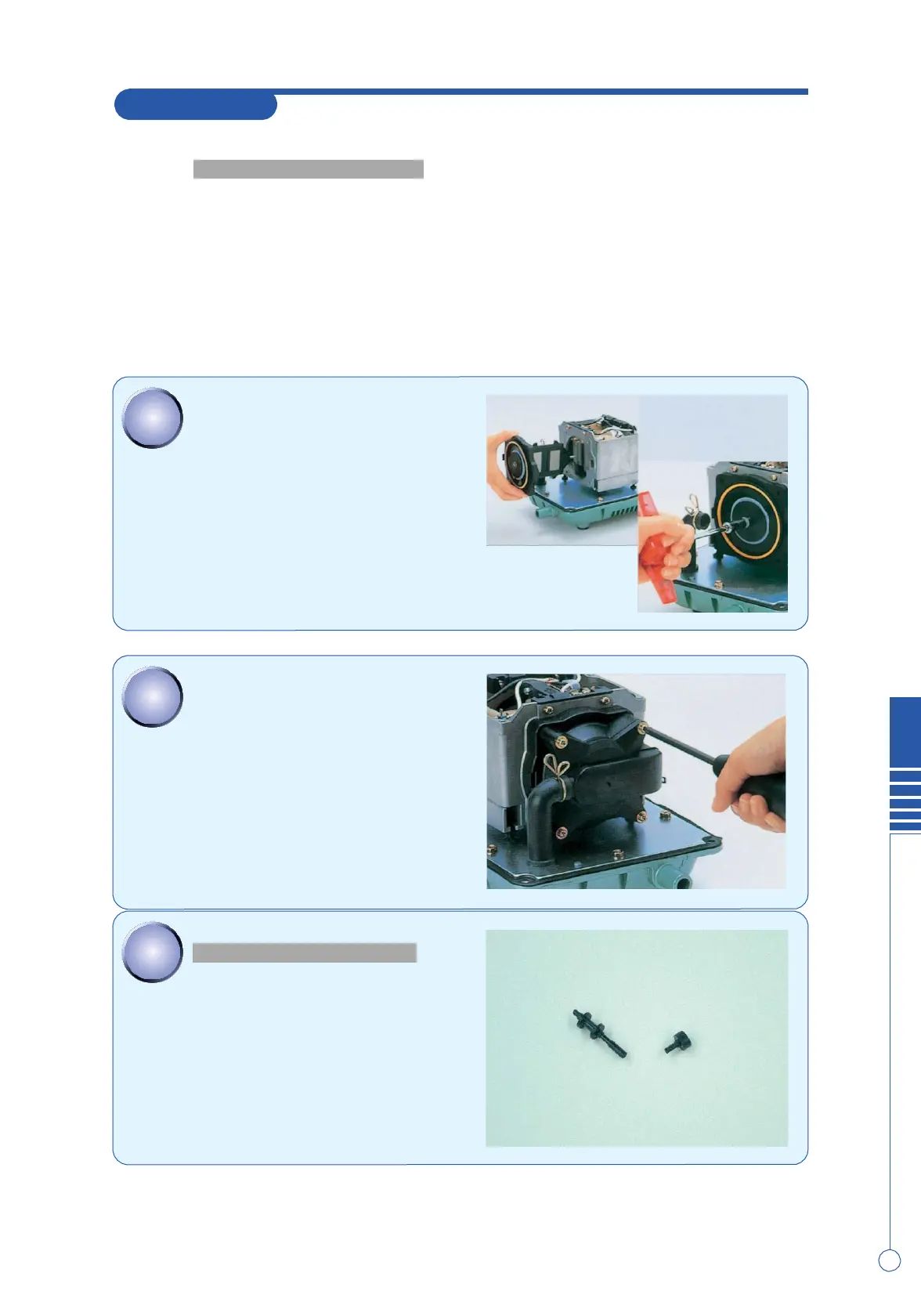

Fit the actuating rod by aligning it with the

groove

and tighten

U-lock

nut and flat washer by the

nut

driver.

●Use new

U-lock

nut and washer, otherwise,

U-lock

nut

may work loose and cause

malfunction.

S

S

T

T

E

E

P

P

1

1

3

3

Insert the actuating rod into the machine body. Be

sure to fit the positioning boss on the

diaphragm

base into the concave part of the frame stay.

Secure the diaphragm

mounting

block on

the

other side and tighten washers and U-lock

nuts

with the nut driver.

Make sure that gap between the actuating

rod

and the electromagnets is

even.

S

S

T

T

E

E

P

P

1

1

4

4

Mount the casing block with screws (4 screws

on

each side).

And insert

L-tube

into the nozzle of casing

A.

Then, fix it with hose clip.

Complete the other casing block in the same

way.

S

S

T

T

E

E

P

P

1

1

5

5

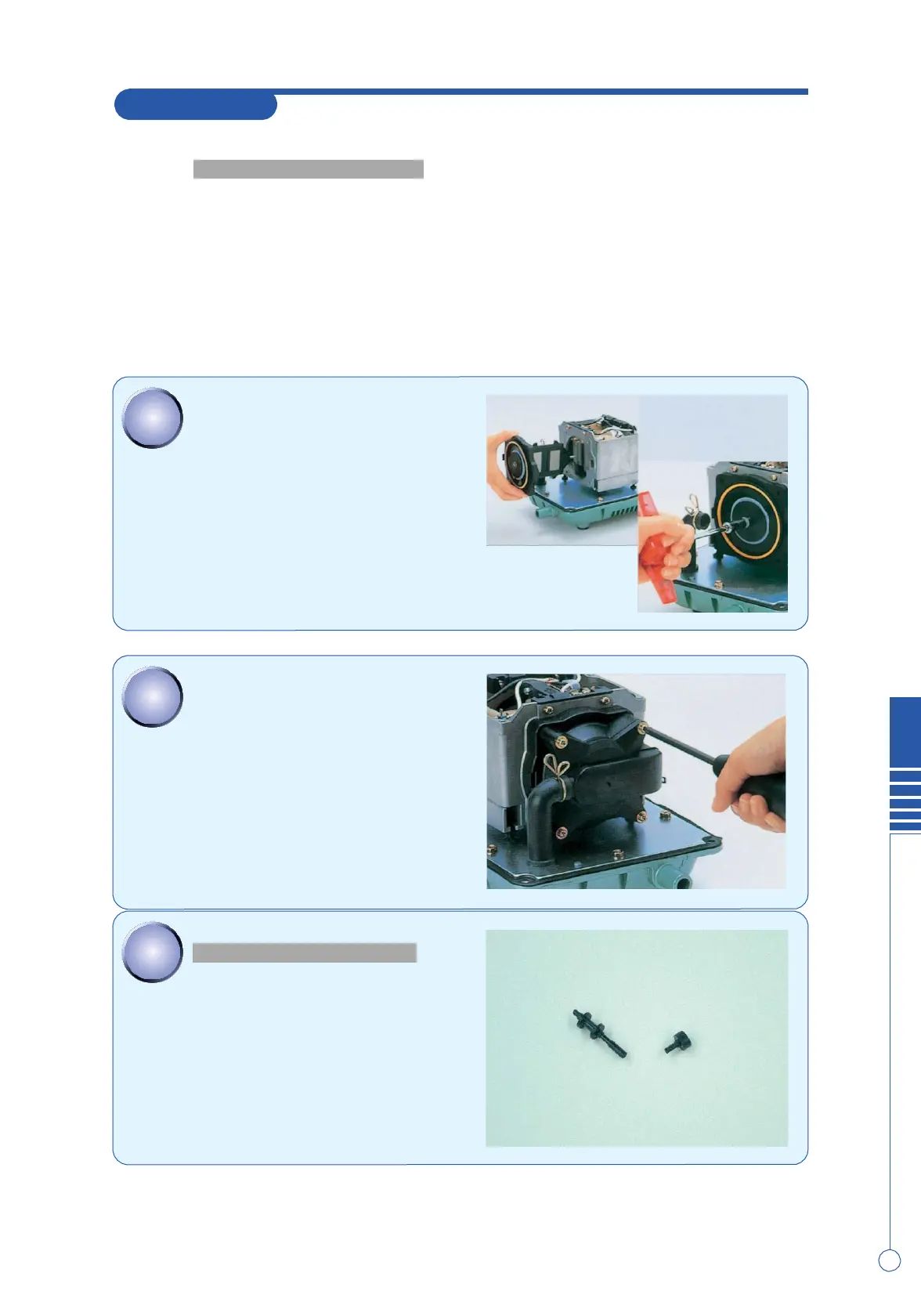

REPLACEMENT OF SAFETY PIN

Check that the broken pin is removed from

unit.

●If the broken pin is left inside the unit, it can get

caught

in between electromagnets and actuating rod,

which

can cause

breakdown.

5

Loading...

Loading...