13

MAINTENANCE

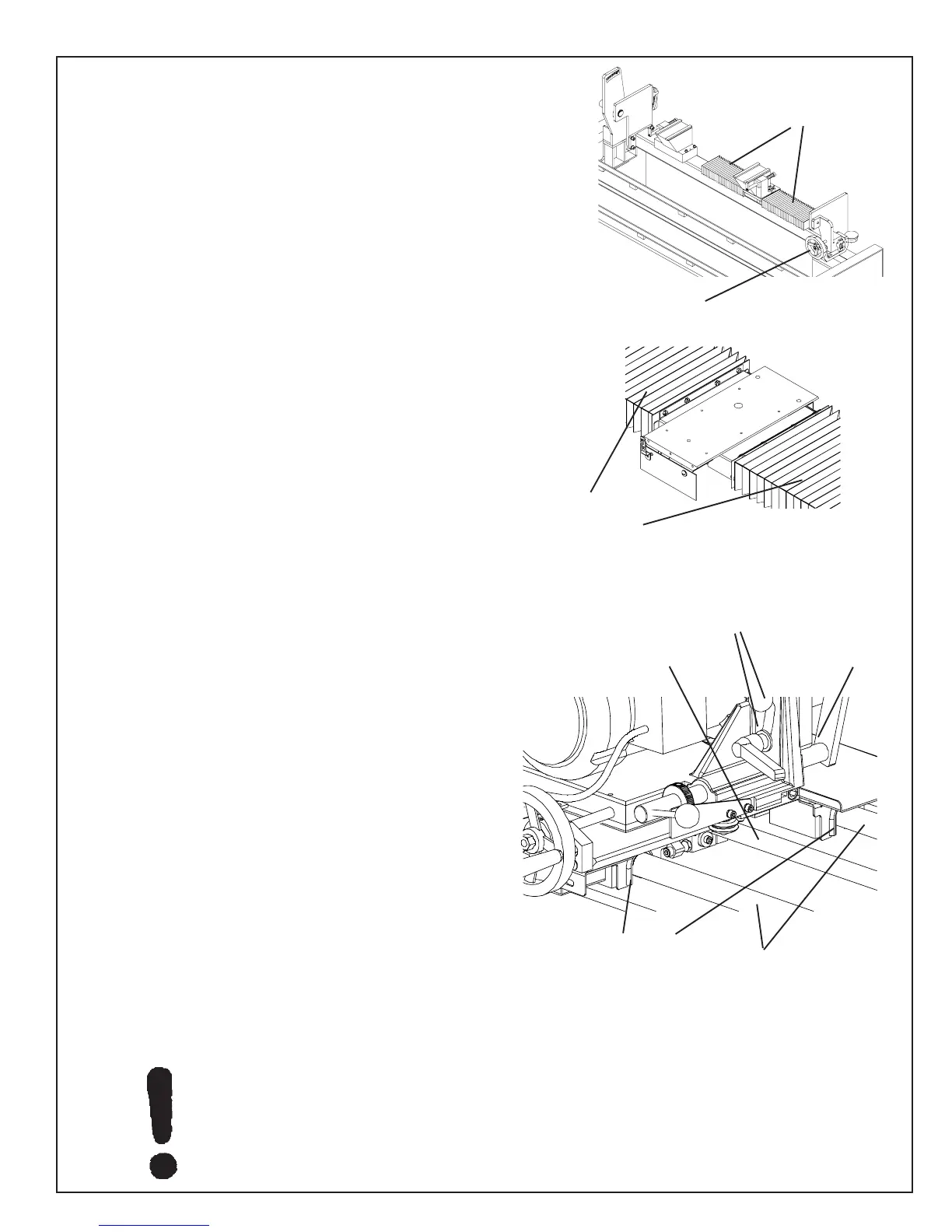

FIG. 14b

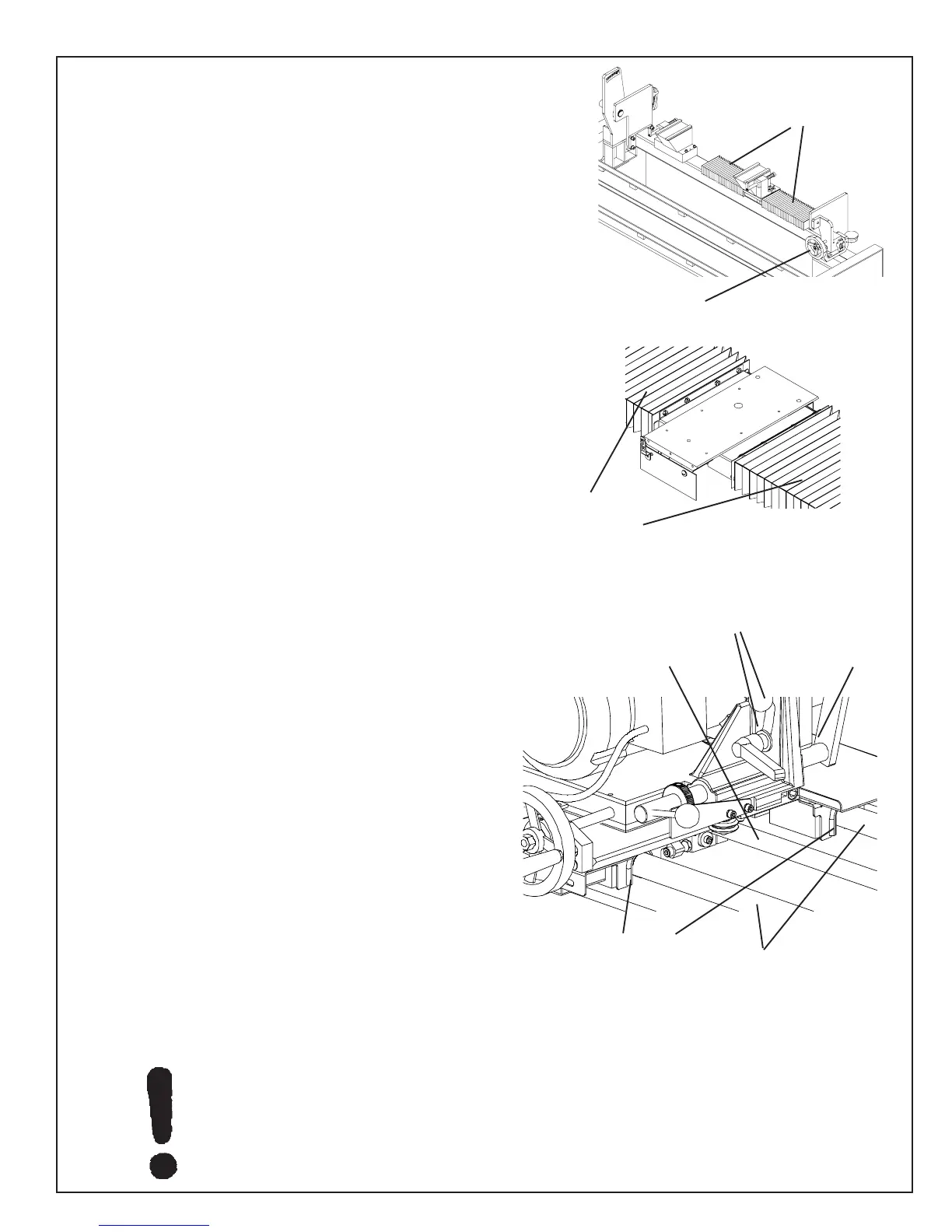

FIG. 15

DAILY MAINTENANCE IS SPECIFIED ON PAGE 6 OF

THE OPERATOR'S MANUAL, AND IS TO BE PER-

FORMED BY THE OPERATOR.

LISTED BELOW ARE PERIODIC MAINTENANCE

ITEMS TO BE PERFORMED BY YOUR COMPANY'S

MAINTENANCE DEPARTMENT:

1. Lift the bellows located on adjustable electromaget (see

FIG 14a) and wipe off the bearing rail monthly. Every 3

to 6 months throughly cleean the rail and flood spray

with WD-40 or an equivalent lubricant. Run the adjust-

able electromagent back and forth through its full range

of travel. With a clean rag, wipe off the excess lubri-

cant. Run the carriage back and forth and wipe the rail

after each pass. Repeat until the rail feels dry.

2. Lift the bellows, (See FIG. 14b) if used, and wipe off the

traverse driveshaft and the bearing rails monthly. When

a squeaking noise is coming from the actuator bearings,

follow the lubrication procedure for actuator and linear

bearings located on the following page. Generally, this

will be every 6 months to a year.

3. Replace the four foam rail wipers (FIG. 15) every 6

months of operation. Note: Wipers are removed if

optional bellows are installed.

4. Clean the interior and the top cover of the Coolant Tank

as necessary and at least every 6 months.

5. Clean the exterior of the diamond dresser arm and

spray with WD-40 or equivalent at least every 6

months.

6. Clean the exterior of the grinding head hieght adjuster

and spray with WD-40 or equivalent at least every 6

months. Move head through full range of motion to

maintian function.

7. Clean the exterior of the right side tooling alignment

adjuster and spray with WD-40 or equivalent at least

every 6 months.

8. Check the brushes on the auto traverse drive motor

once every 36 months. Replace as necessary.

THE UNINTERUPTABLE POWER SUPPLY (UPS) WHICH IS

USED AS A BACKUP TO HOLD THE BEDKNIFE TO THE

ELECTROMAGNETS DURING A POWER INTERUPTION

HAS A BATTERY. THIS BATTERY HAS A THREE YEAR LIFE

AND MUST BE REPLACED AFTER THREE YEARS OF

SERVICE LIFE. SEE THE PARTS LIST FOR REPLACE-

MENT BATTERY PART NUMBER.

Carriage Rails

Foam Rail

Wipers

Drive Shaft

Carriage

Bellows

Diamond

Dresser Arm

Grinding Head

Height Adjuster

FIG. 14a

Adjustable Electro-

magnet Bellows

Right Side Tooling

Alignment Adjuster

Loading...

Loading...