20

ADJUSTMENT (Continued)

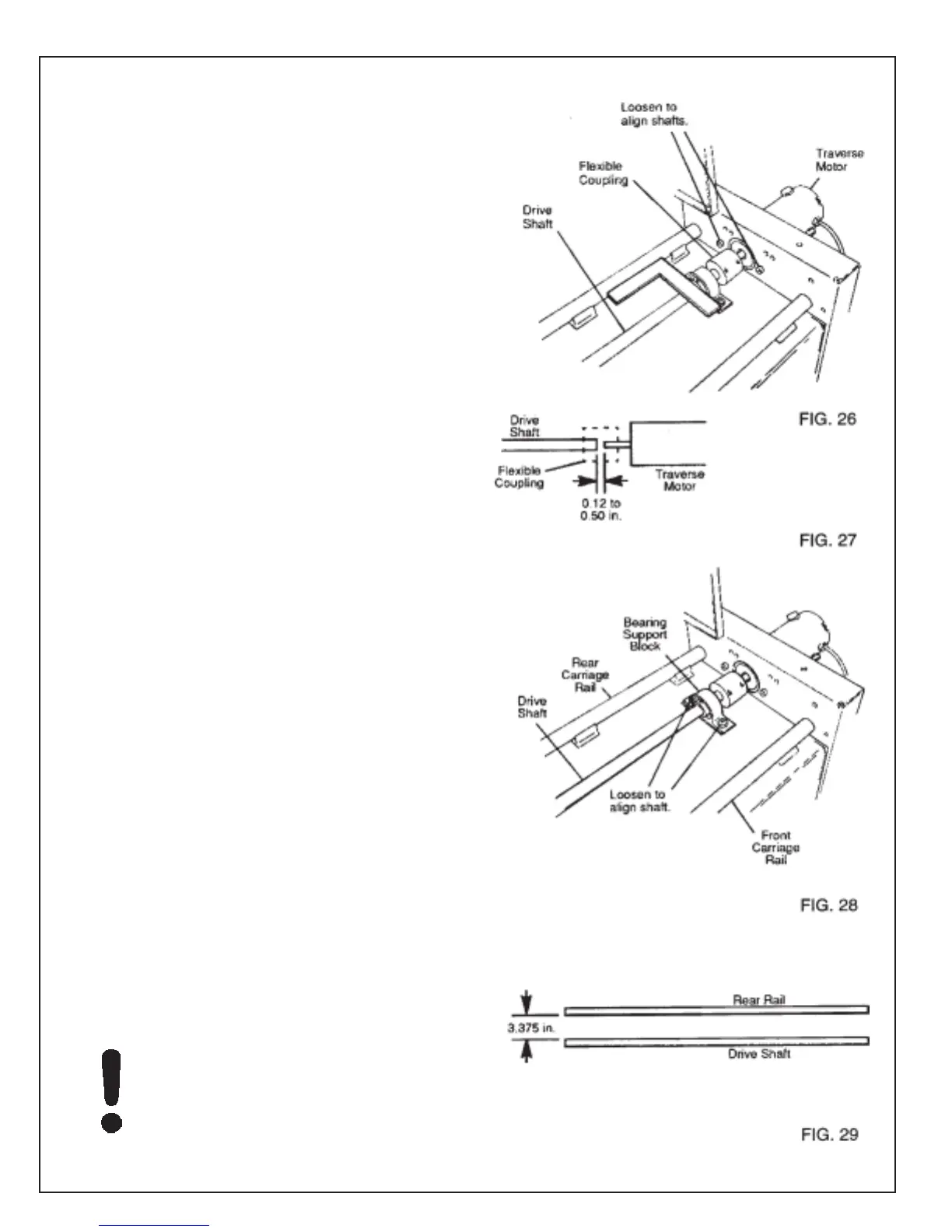

TO ALIGN THE MOTOR SHAFT AND DRIVE

SHAFT

There must be 0.12 to 0.50 in. (3.0 to 12.7 mm) end

clearance between the traverse motor output shaft and

the drive shaft, inside the flexible coupling (FIG.27).

To prevent drive shaft "whipping" at higher traverse

speeds, the two shafts must be aligned so they are

concentric within .010 in. [0.25 mm]. To align:

1. Loosen the two set screw in the coupling.

2. Remove the cover on the outside of the right leg.

3. Loosen the two bolts which secure the motor

assembly to the leg.

4. Visually align the two shafts, then tighten the

motor mounting bolts. Reinstall the leg cover.

5. Check that the spiral gaps in the flexible

coupling are equally spaced, with no compression

or extension load on the coupling, then tighten the

coupling screws.

6. Check that the bearing load block is at 90

o

to the drive shaft (within +/- 1/4 degree). Use a

precision square held against the bearing

shoulder and the rear rail, as in FIG. 26.

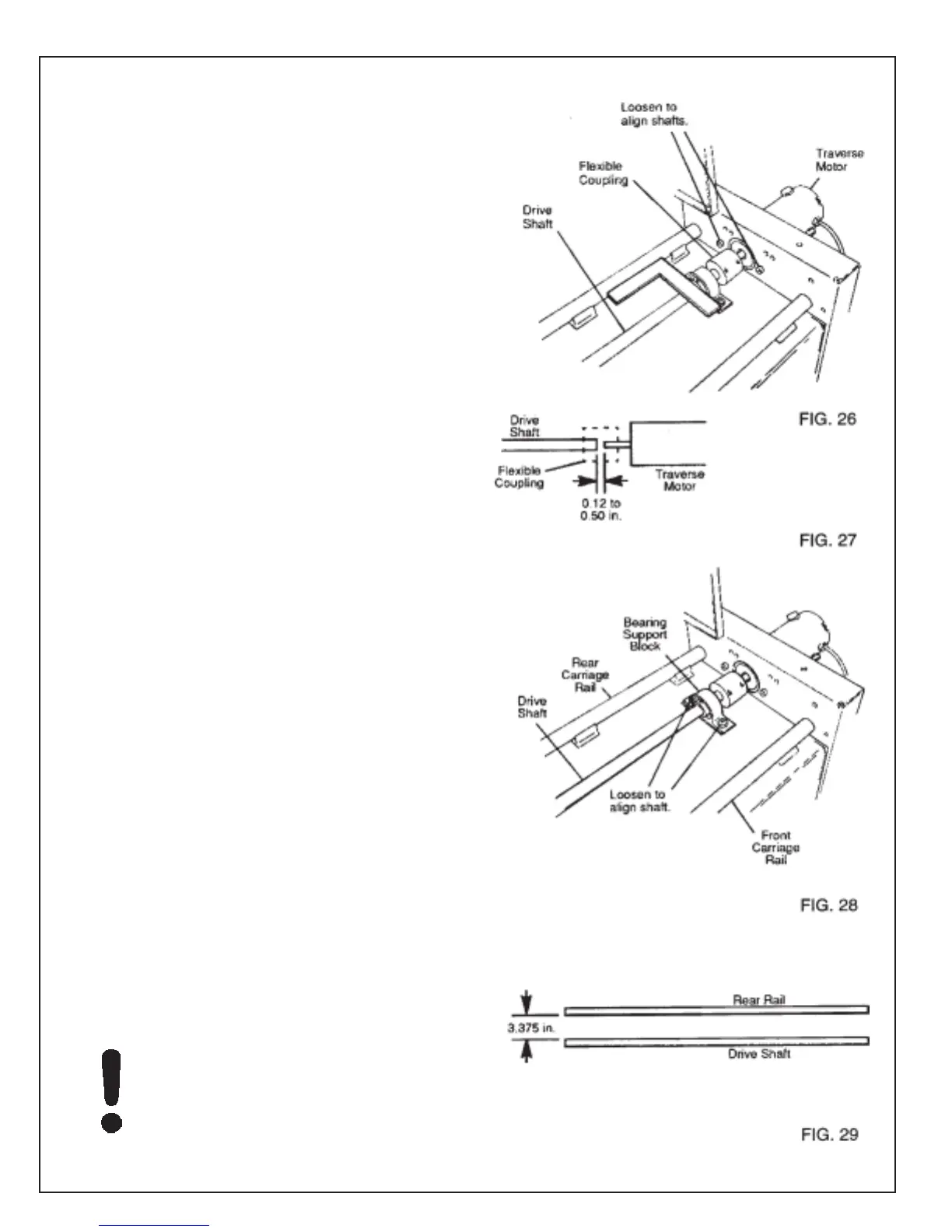

TO ALIGN THE REAR RAIL AND DRIVE SHAFT

The rear carriage rail and the drive shaft must be

precisely aligned:

1. Loosen the two bolts holding the bearing support

blocks at each end of the drive shaft. FIG. 28.

2. Align the drive shaft and rear carriage rail (FIG.

29) so the distance between their facing surfaces

is 3.375"+/- .010 [85.75 mm +/- 0.25]. See FIG.

29.Then tighten the support block bolts.

3. Check that the bearing support blocks are still at

90

o

to the drive shaft (within +/- 1/4 degree).

Use a precision square held against the bearing

shoulder and the rear rail.

4. If you have difficulty obtaining the above alignment,

check the straightness of the carriage rails (see

below).

NOTE: The vertical and horizontal straightness of the

rails is very accurately set at the factory, so they are

unlikely to be incorrect. Contact the factory if you sus-

pect a problem after making the following tests.

If the drive shaft is adjusted, you

may have to realign the motor shaft

and drive shaft (see above).

Loading...

Loading...