2

ACDC Motorized Solutions Pty. Ltd.

RollerGlide Rolling Door Operator

Installer fitting instructions

Introduction

If this is your first installation of a RollerGlide automatic rolling door operator, please

read and fully understand the instructions before proceeding. For more information

and product updates visit our Web site http://www.acdcms.com.au.

Check contents in the installation kit

RollerGlide automatic rolling door operator

Power lead

Two remote transmitters

Owner manual & Warning label

Extension forks & weight bars (x2)

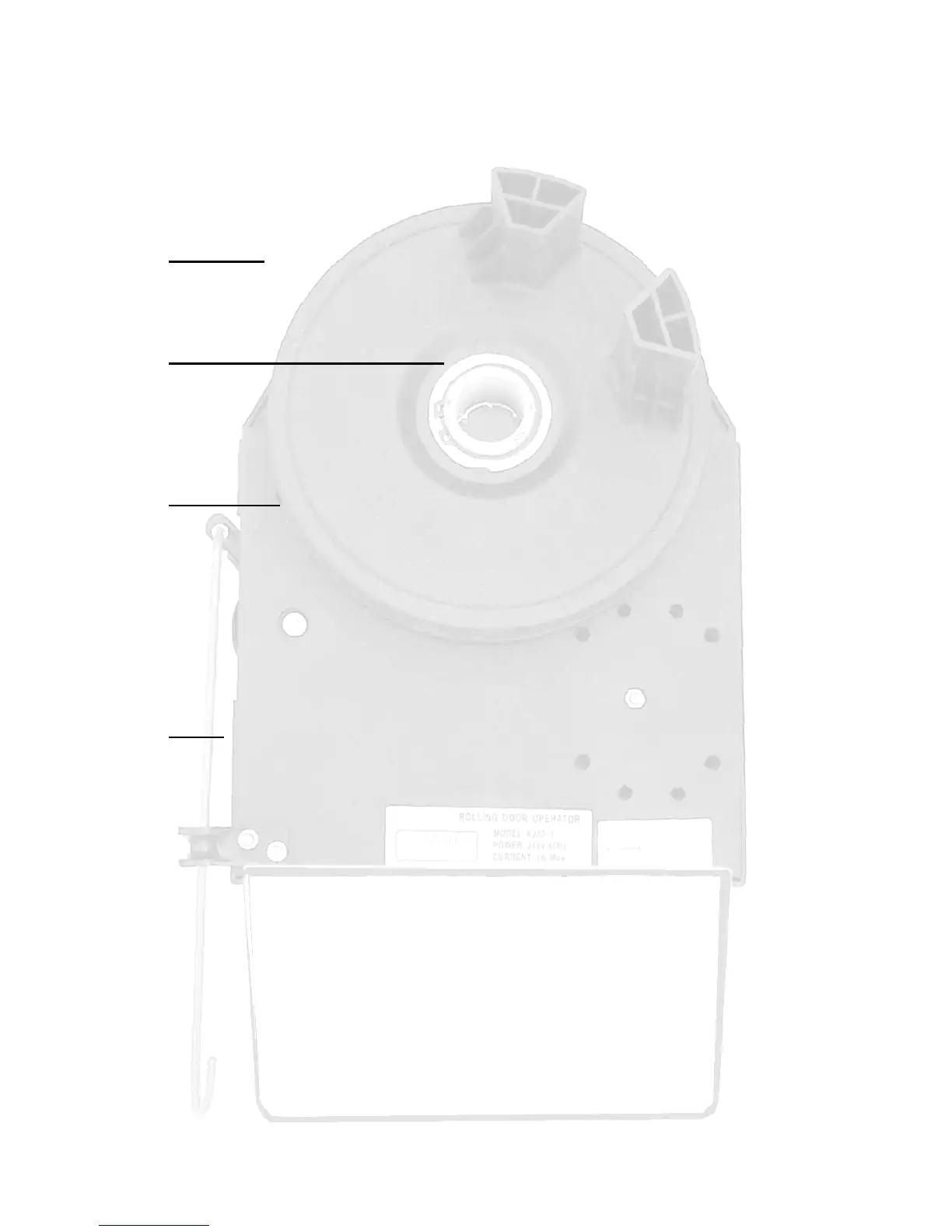

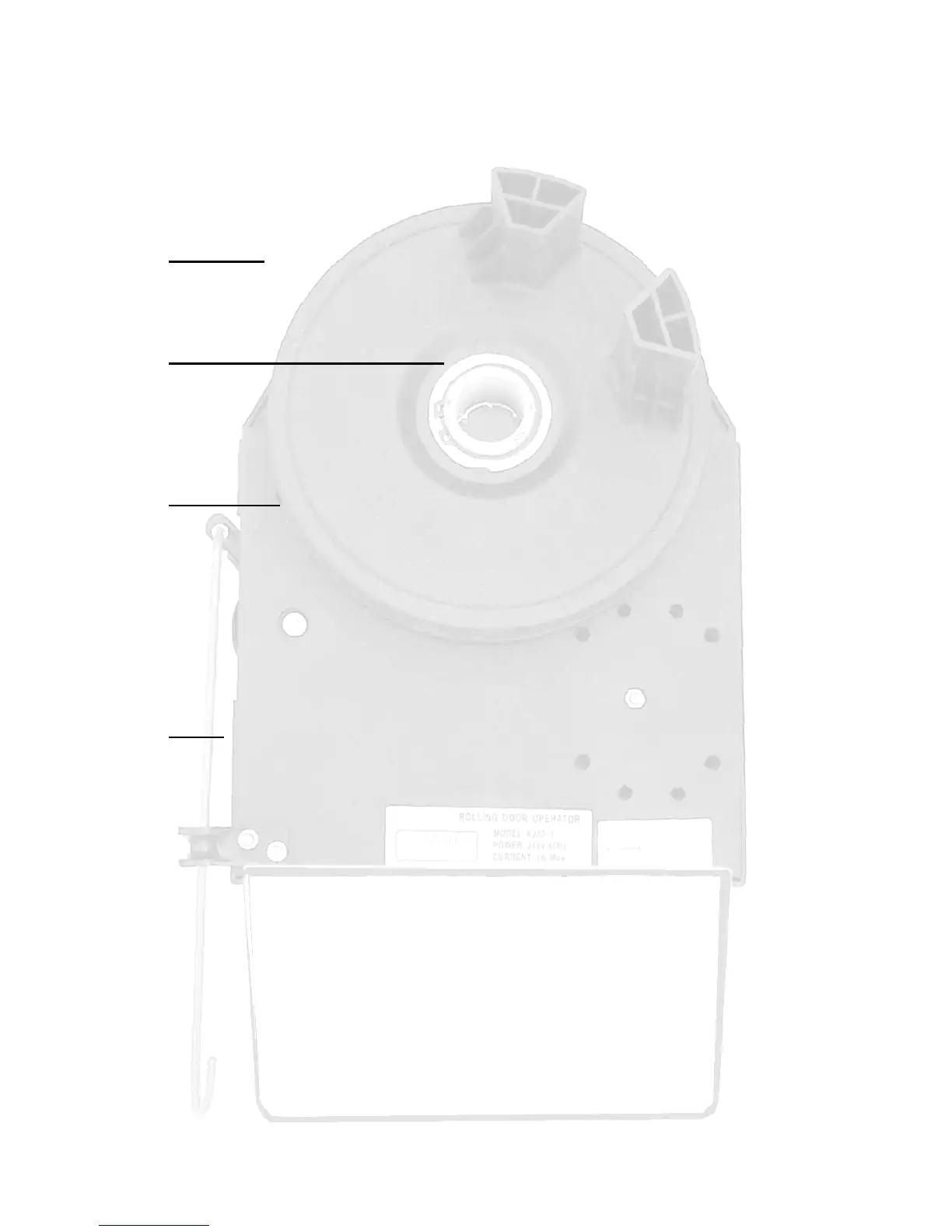

Tools required (see figure 1)

Extension socket set, to fit the existing U-bolts on the door

• A 14mm spanner or socket to tighten the RollerGlide bolts

• Door support or prop

• A ladder to reach the top of the door

• Rope or strap to secure door curtain

• Lifting bar (piece of strong steel pipe) to fit inside the door support shaft to aid

lifting

• Small bladed screwdriver to adjust internal controls

• Use a helper if possible to assist with the installation

Checks (see figure 1)

• The door must be in good working order

• Some doors require the fitting of a weight bar that sits in the bottom of the

door to provide a small amount of extra weight; this stabilizes the bottom of

the door when closing and provides inertia to allow the door to fully close.

They are usually a rectangular length of mild steel weighing about 2kg

• Tighten the U-bolt clamp on the opposite end to where the RollerGlide is to

be installed

• All existing door locks should be removed or warranty will be void

• The RollerGlide is fitted between the door mounting bracket and the door

roller. The minimum distance needed is 70mm. If the distance is not sufficient

the mounting bracket may need to be adjusted.

• The unit is shipped to fit a right hand installation

(Viewed from inside the garage)

• Use the service lever to disengage the unit so that the large fork wheel freely

rotates

• Changing from right to left mounting (see figure 3)

• The motor power plug is moved from socket A to socket B changing the

operator from right to left hand operation

Loading...

Loading...