8

Functions

– Hole patterns (DRO203, DRO300)

– Programming of machining steps (DRO300)

Automatic calculation of bolt hole

patterns for milling and drilling

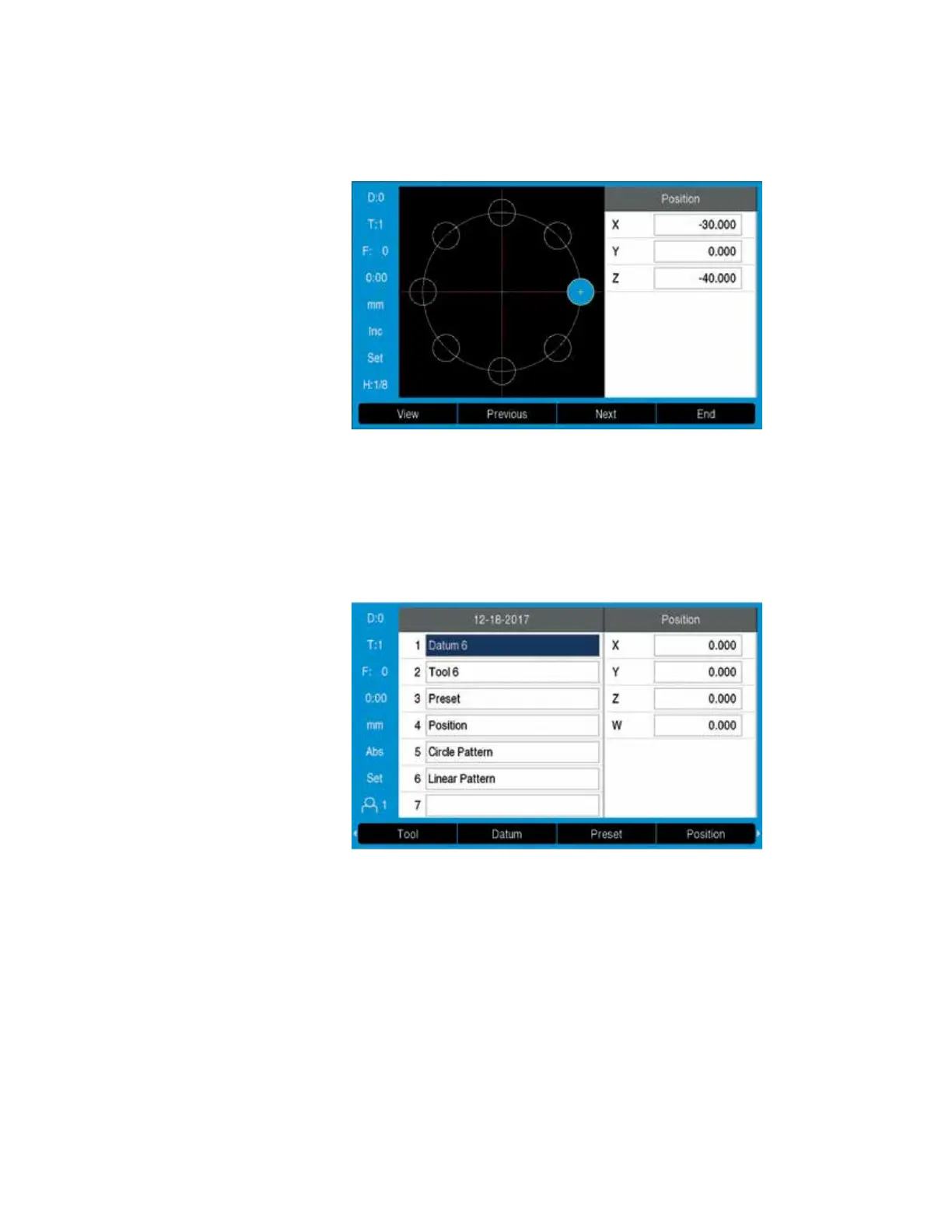

In milling machine mode, you can machine

circular hole patterns (full circle or circle

segments) and linear hole patterns without

much calculation.

You simply enter the geometric dimensions

and the number of holes from the drawing.

The display calculates the coordinates of the

individual holes in the working plane. You

only need to traverse “to zero” and drill. The

display then shows the next position. The

graphic display is a particularly useful

feature: it lets you verify your input for the

programmed bolt-hole pattern before

machining.

Programming machining steps

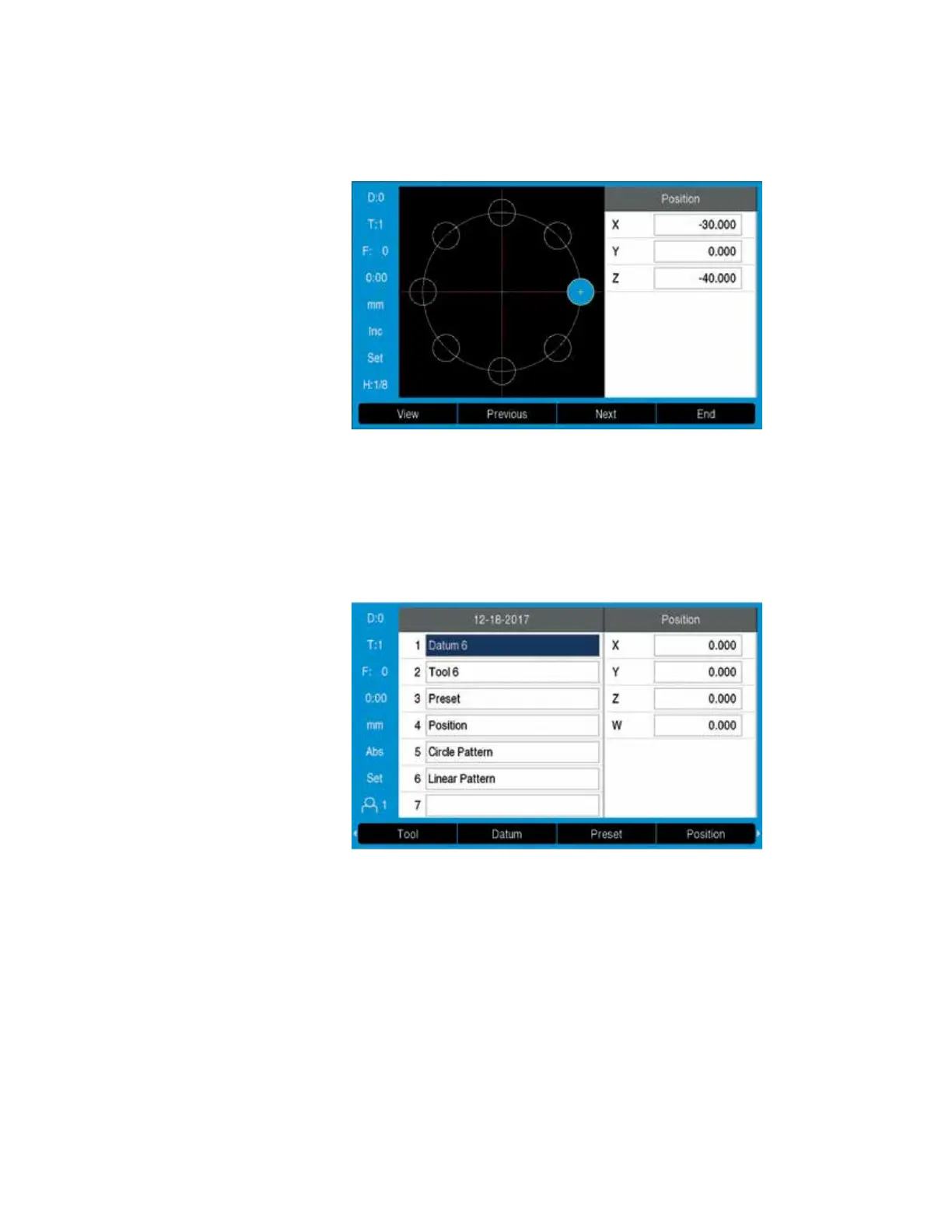

The programming functions of the DRO300

allow you to save repetitive machining steps.

For example, you can save all of the

machining steps required for a small batch in

the form of a program. In the RUN mode of

operation, the distance-to-go display will

guide you step-by-step to the programmed

positions.

You create programs by typing in the

positions step by step. The xed cycles such

as Bolt Hole Circle, Linear Hole Pattern,

Incline Mill Form or Circular Arc keep your

programs short and save you programming

time. In the course of your work, the readout

presents each nominal position in the proper

sequence. You need only move from one

position to the next.

Loading...

Loading...