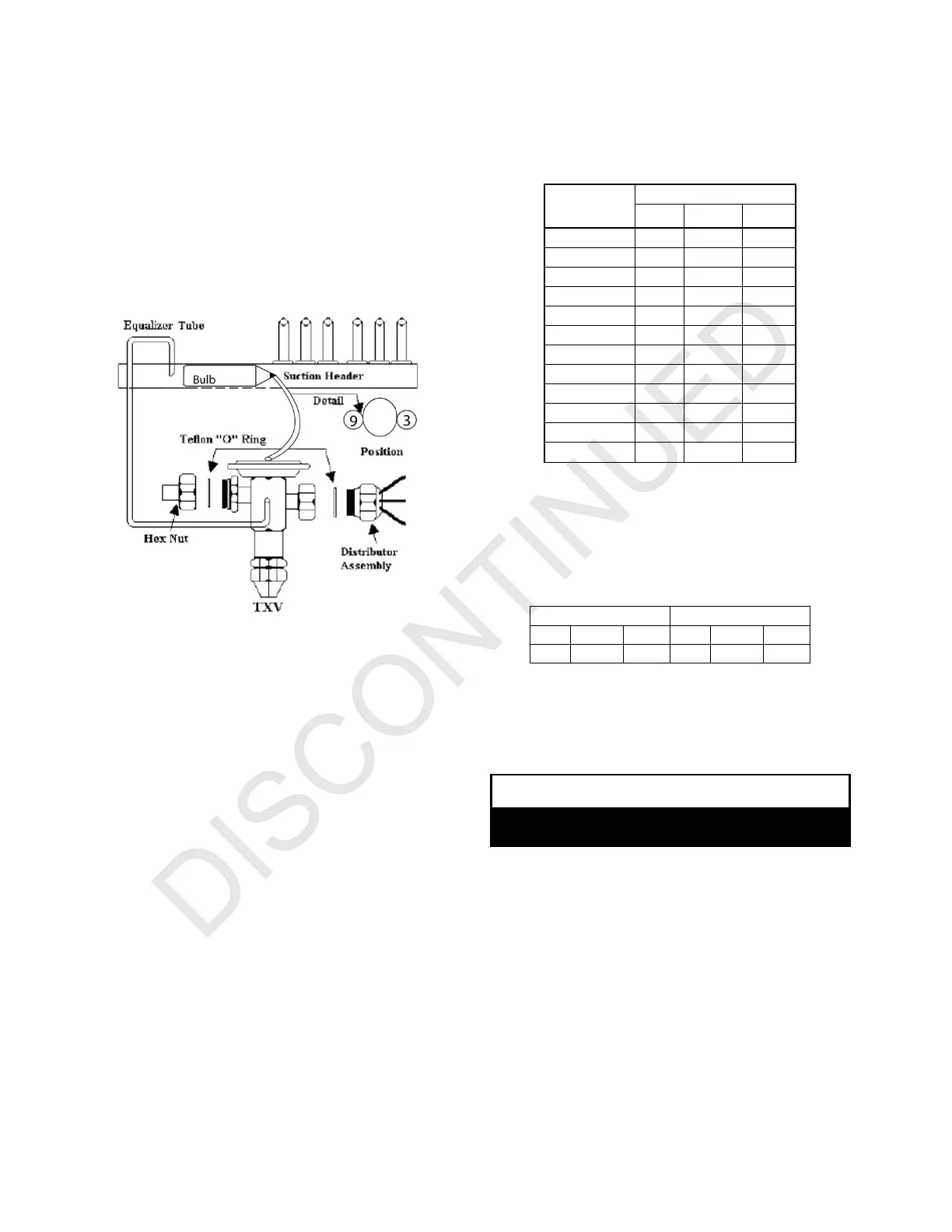

When changing pistons use the following procedure:

1. Loosen hex nut located on liquid line and separate

from distributor assembly.

2. Remove the existing piston from inside the distributor

assembly

3. Insert the desired ADP piston into the distributor

assembly.

4. Inspect “O” ring and replace if damaged. Ensure

gasket is in place.

5. Re-install florator nut to body and torque to 10 ft-lbs.

THERMAL EXPANSION VALVES

As shipped from the factory, the TXV installed in each coil is

chosen for the nominal BTUH capacity of

the coil.

If the sensing bulb on the TXV is removed during

installation of the air handler be sure the bulb is relocated to

the suction header as shown above. Wire ties or straps

should be used to hold bulb in position. Cork tape or

insulation wrapped around bulb will improve accuracy of

mechanism.

Field installed TXV kits are also available. Refer to

engineering guide or price sheet for sizes, and kit

instructions for installation procedures.

REFRIGERANT CHARGING INSTRUCTIONS

Outdoor temperature should be 60°F or higher. Set the

system to cooling mode and charge per the applicable

method listed below. For Heat Pump units initially charged

in cooling mode, final adjustment to charge in heating mode

is acceptable if necessary. When charging Heat Pumps in

the heating mode please refer to the outdoor unit’s charging

instructions.

FIXED ORIFICE 1. Run system for at least 10 minutes to

allow pressure to stabilize. 2. Add or recover refrigerant

until the superheat matches the table below.

Outdoor Air

Temp. (°F)

Min Nom Max

EXPANSION VALVE 1. Run system for at least 10

minutes to allow pressure to stabilize. 2. Add or recover

refrigerant until the subcooling matches the table below. 3.

If equipped, adjust the valve until the superheat matches

the table below.

CONDENSATE DRAIN

CAUTION!

Unit is equipped with side and bottom openings. If

bottom openings are not used- they must be plugged!

Determine the drain connections to be used and note the

difference between the primary and

secondary openings.

If side openings are used, use screwdriver to remove

webbing from selected openings.

It is recommended that ¾‘’ male pipe thread PVC fittings be

used at the condensate pan. Do not over-tighten.

Tubing for all condensate drains should be a minimum of

7/8‘’ OD. The drain should be pitched downward 1‘’per 10‘.

Install a 3‘’ trap as close to the coil as possible.

Loading...

Loading...