MK Series Portable Chiller : Air-Cooled : HE INSTRUMENT

Page: 60

ADVANTAGE ENGINEERING, INC.

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-0729 Fax: 317-881-1277

Service Department Fax: 317-885-8683

Email: service@AdvantageEngineering.com

6.1 WATER SYSTEM

A. MOTOR/PUMP ASSEMBLY: the

motor/pump assembly circulates

chilled fluid to the process loop.

The pump assembly is built of total

stainless steel to maintain water

quality (figure 6.1A).

B. FLOW SWITCH: the flow switch is

a paddle-type switch mounted in

the from process water line. The

primary function of the flow switch

is to monitor water flow. If the flow

drops 33%, the switch will stop the

refrigerant circuit. This protects the

evaporator from freezing due to

low flow (figure 6.1B).

C. FREEZESTAT: the freezestat aids in

protecting the evaporator from

potential freezing. The freezestat is

factory adjusted to 40°F. The

freezestat must be field adjusted for

operating with setpoints below

48°F (figure 6.1C).

6.2 REFRIGERATION SYSTEM

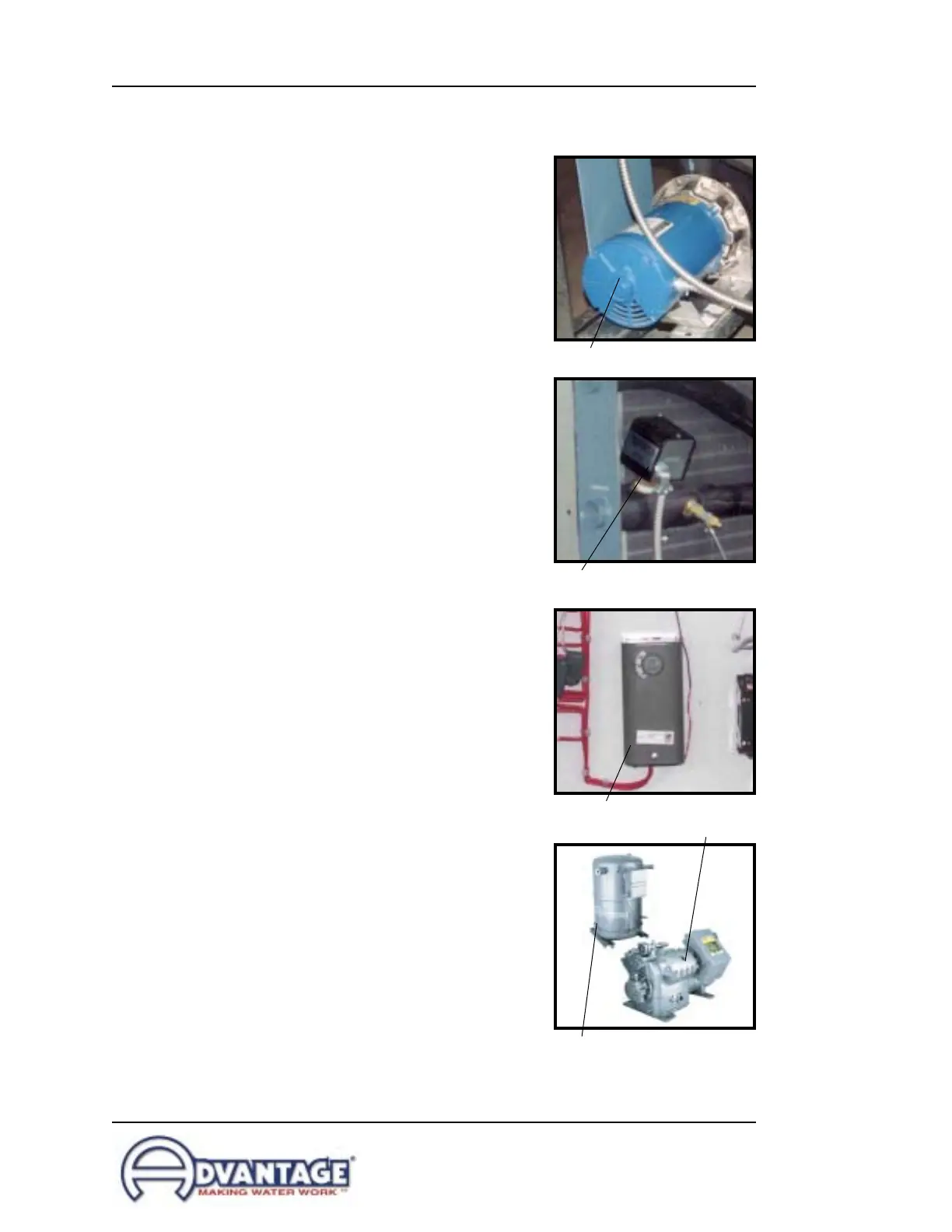

A. COMPRESSOR: hermetic or semi-

hermetic compressors take low

pressure/low temperature

refrigerant gas and compress the

gas into high pressure/high

temperature gas (figure 6.2A).

B. AIR COOLED CONDENSER: the air

cooled condenser removes BTU’s

from the compressed refrigerant

gas. The action causes the gas to

“condense” into a liquid state still

under high pressure. Air flow across

the condenser is achieved via a

motor driven fan assembly or

centrifugal blower (figure 6.2B).

C. FILTER-DRIER: the filter-drier

removes contaminants and

moisture from the liquid refrigerant

(figure 6.2C).

Flow switch

Figure 6.1B

Mechanical freezestat

Figure 6.1C

Hermetic compressor

Semi-hermetic compressor

Figure 6.2A

Pump Motor Assembly

Figure 6.1A

Loading...

Loading...