RevC 07/15/13 Page 30

attempt to add enough fuel to hit the target AFR.

Note:

The

calculated

LambdaTarget

influences

the

fuel

delivered

to

the

engine

at

all

times,

even

when

closed-loop

02

feedback

is

disabled.

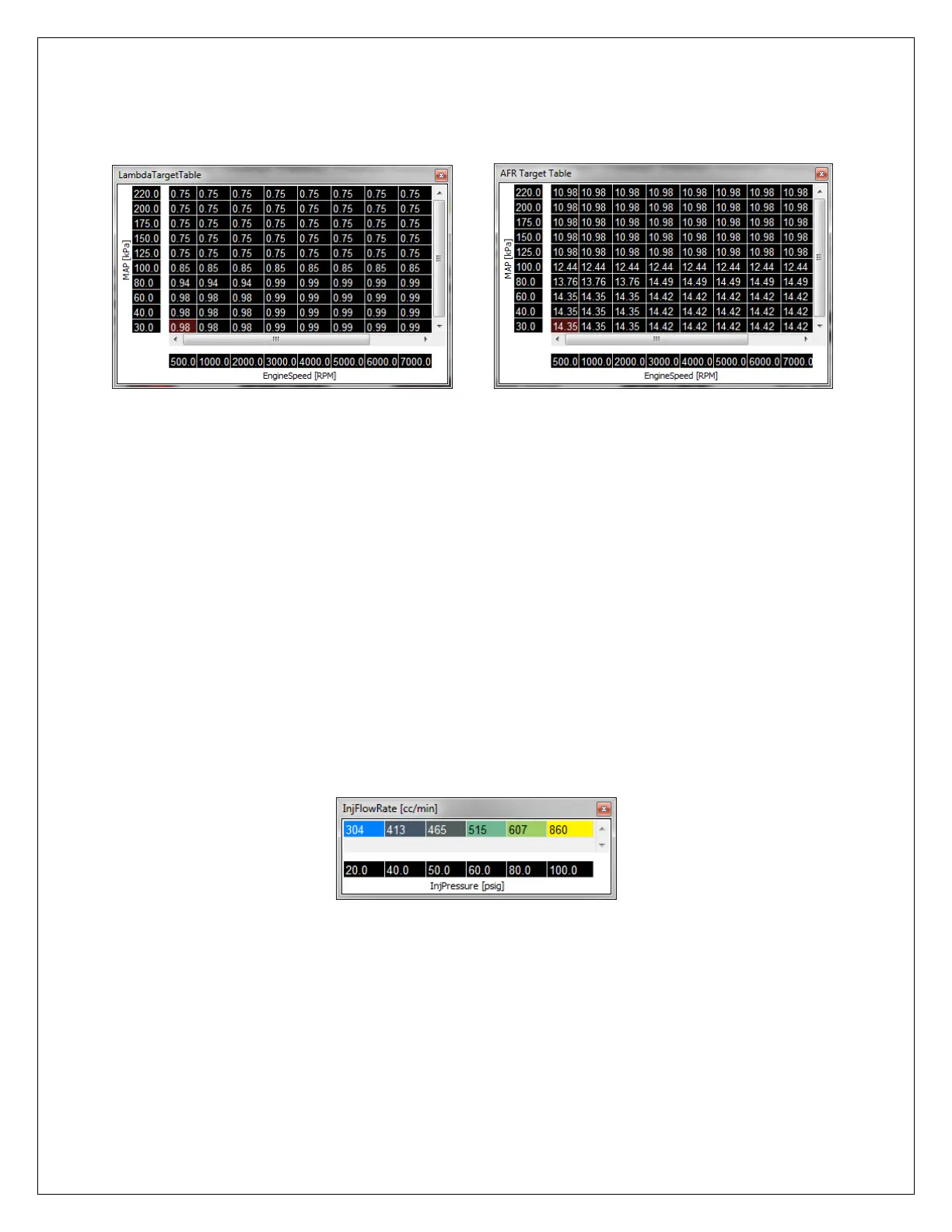

The suggested tuning method is to set the AFR using the LambdaTargetTable or AFR

Target Table to a value safe and suitable for the engine. For normally aspirated

engines a value of 13.0:1 or 0.887 lambda is usually sufficient at all operating

conditions. For boosted applications, the operating conditions dictate a safe AFR.

Please consult a tuner knowledgeable in your engine’s requirements for help. Once the

target lambda (AFR) values are chosen, run the engine at as many operating conditions

as possible and adjust the VE Table to reach the AFR Target Table values. Once the

VE Table has been tuned to accurately reach the AFR Target Table values at all

operating ranges, then you can change the AFR Target Table to use different AFR

settings later. Never adjust VETable to run a different AFR, only to achieve the

LambdaTarget value.

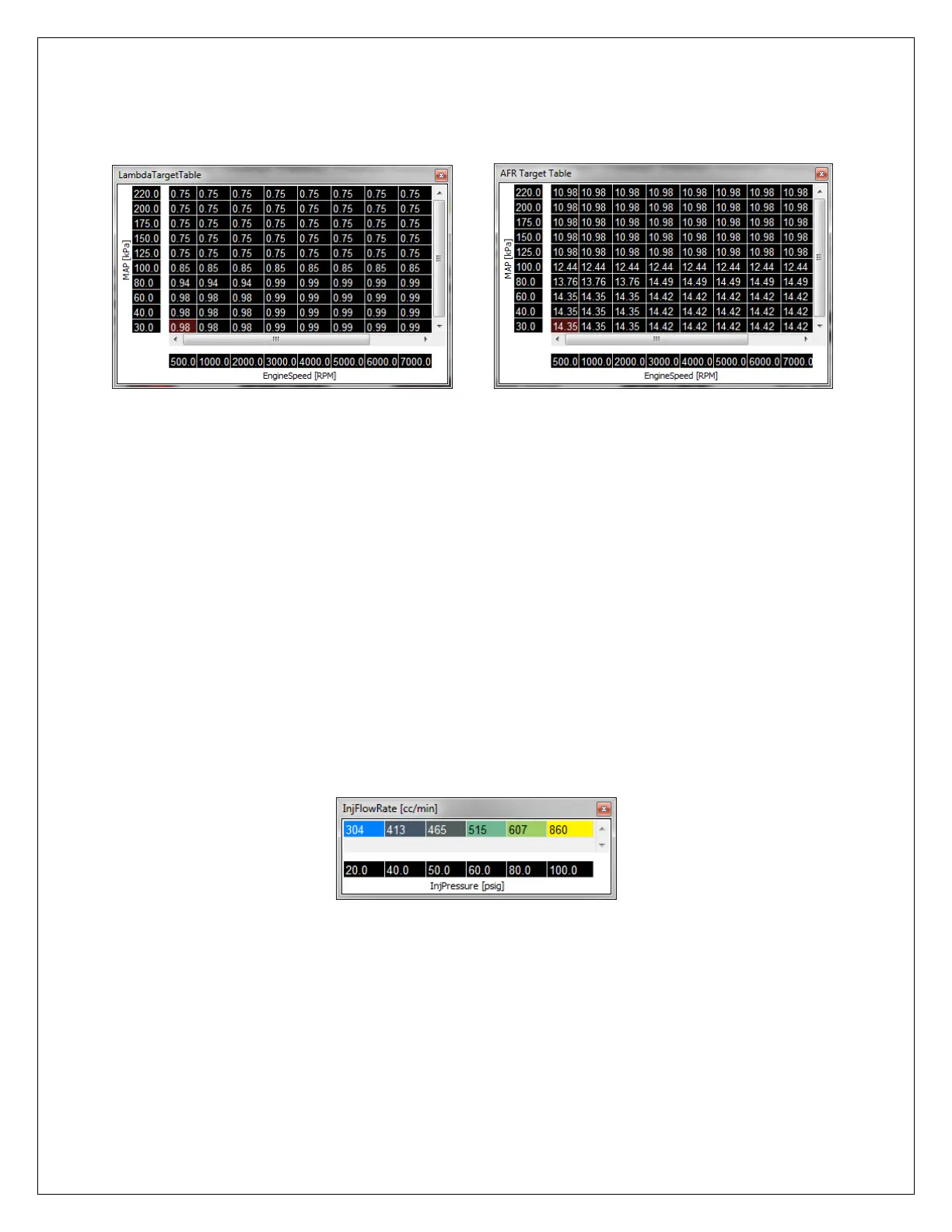

The Injector Flowrate is very important in determining the fuel requirements. The Infinity

ECU uses actual Injector Flowrate [cc/min] to determine the proper injector pulse width.

The InjFlowRate [cc/min] table is calibrated from the Setup Wizard: Injector Flow,

however the table can be modified manually for unlisted injectors.

Now that the base injector flow rate has been determined, the Infinity ECU applies a few

more compensating factors. Wall Wetting is a function of fuel condensing in the intake

manifold at the injection point. At different rates of change in the MAP [kPa] values, and

at different Coolant Temperatures, fuel enrichment compensations are used to prevent

lean and rich conditions during rapid manifold pressure changes. The WallWetting 2-

axis table can be adjusted to create a smooth fuel response. Note that this table has

several different functions. It can be used for dynamic transients by nature of its “MAP

Rate” x-axis. It can also be used for more steady state compensations by adjusting the

values in the “middle band” of the table where MAP rate changes are very small.

Positive numbers in this table will effectively add fuel to enrichen the mixture. Negative

numbers have the opposite effect.

Loading...

Loading...