29

foreign particles suspend in it and can easily drain with lubricating oil.

(2) Clean the installation surface of the oil drain plug on the oil pan. Fit the drain plug with a new gasket and tighten it

by 80 N·m.

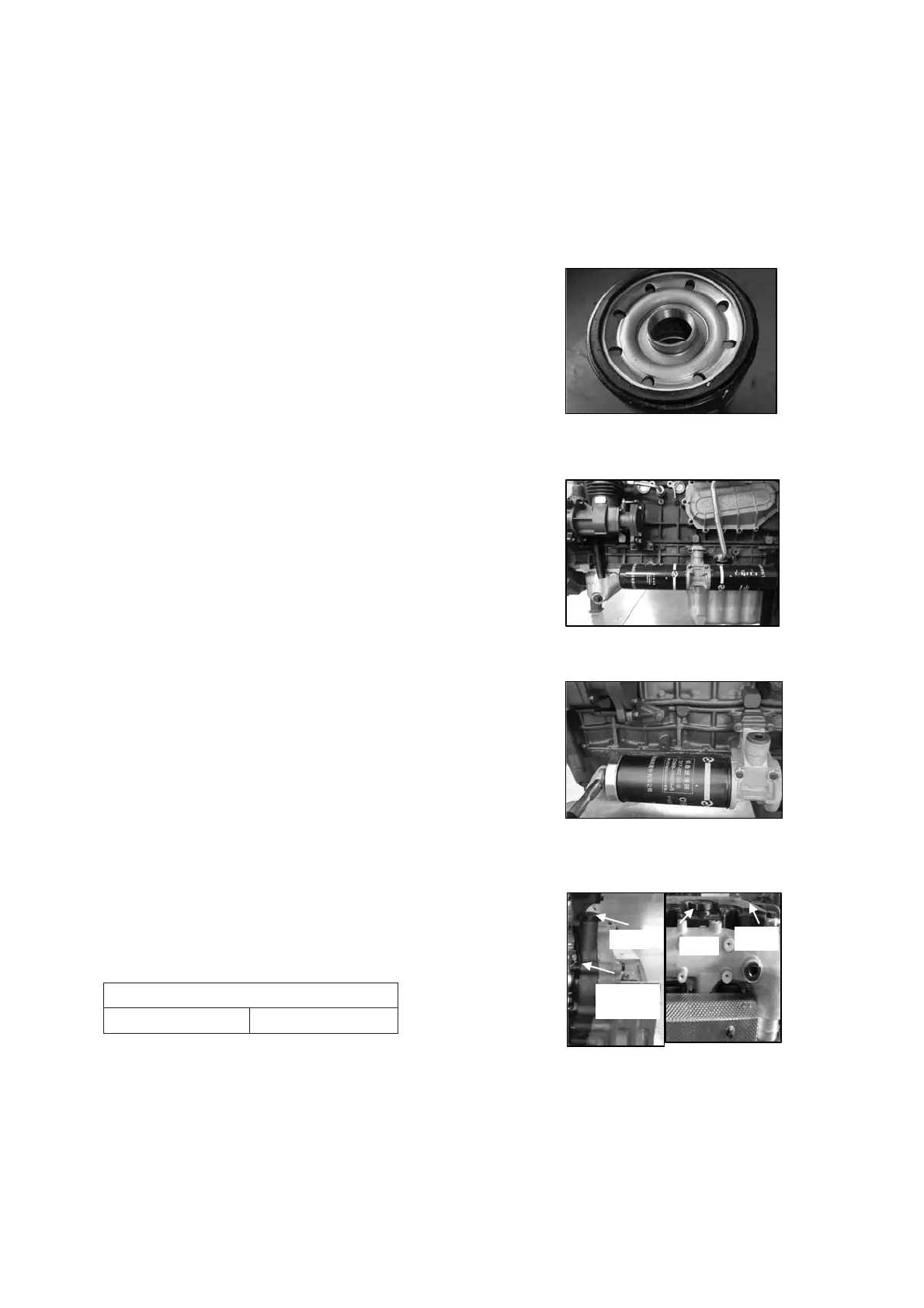

(3) Clean the outside surfaces of the oil filters. Remove the oil filters with tool and scrap them.

(4) Clean the sealing surfaces of the filter heads, and there should be no old O-ring left.

(8) Start the engine and keep it running at idle, and then check the oil filter and drain plug for oil leaks.

(9) Shut off the engine, wait for about 10 minutes to provide enough time for the oil to flow into the oil pan, and check

the oil level. If required, add lubricating oil until it is near the upper mark in the oil dipstick (high oil level).

(10) Install the filler cap and tighten it until you feel suitable.

(5) For the SC12E engine, fill the filters with clean oil from

the peripheral holes before installation. The oil level should

be 3-15mm below the threaded hole. Apply a light film of

clean lubricating oil to the O-rings on the new filters to form

a lubricating film.

Caution: Do not add oil from the central hole of a

filter.

For the SC10E engine, only apply a light film of clean

lubricating oil to the O-rings on the new filters to form a

lubricating film.

(6) Turn the filters by hand until the O-rings touch the

sealed surfaces of the filter heads, and further tighten

them by 38-42 N·m with tool. For the SC10L engine, it is

required to use a special too to tighten the filters.

(7) Open the filler cap, and fill the engine with clean

lubricating oil until the oil level is near the upper mark in

the oil dipstick (high oil level).

Engine lubricating system capacity

40 L (SC10E) 45 L (SC12E)

Fille

Rear gear

housing

Cover

Fille

Loading...

Loading...