33

4.3.19 Checking belt tensioner

4.3.20 Checking fan bearing

4.3.21 Checking turbocharger

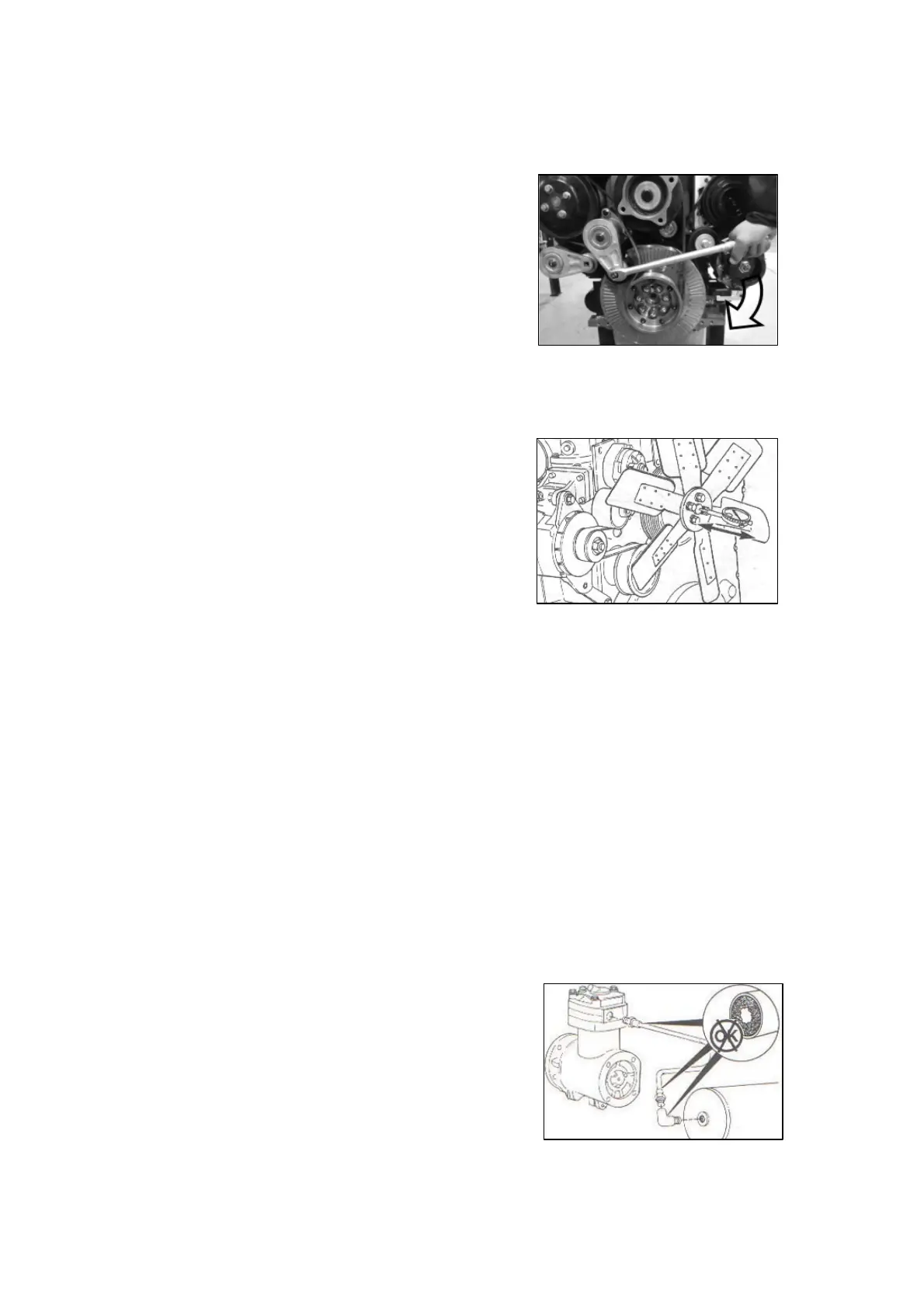

Perform visual check on turbine and compressor blades of the turbocharger for damage, crack, or contact with their

housings when a light finger pressure applied on them. And check the turbocharger shaft for not being free spinning.

In case that any of the above problems occur, the turbocharger should be replaced.

4.3.22 Checking vibration damper

Check the vibration damper for damping fluid (silicon fluid) leak and surface dents. Also examine the thickness of

damper to confirm if the damper has become deformed. In case that any of the above problems occur, the damper

should be replaced.

4.3.23 Checking air compressor

ŸWarning: Air pressure should be released from the air system before removing parts from the air

compressor to avoid personal injury.

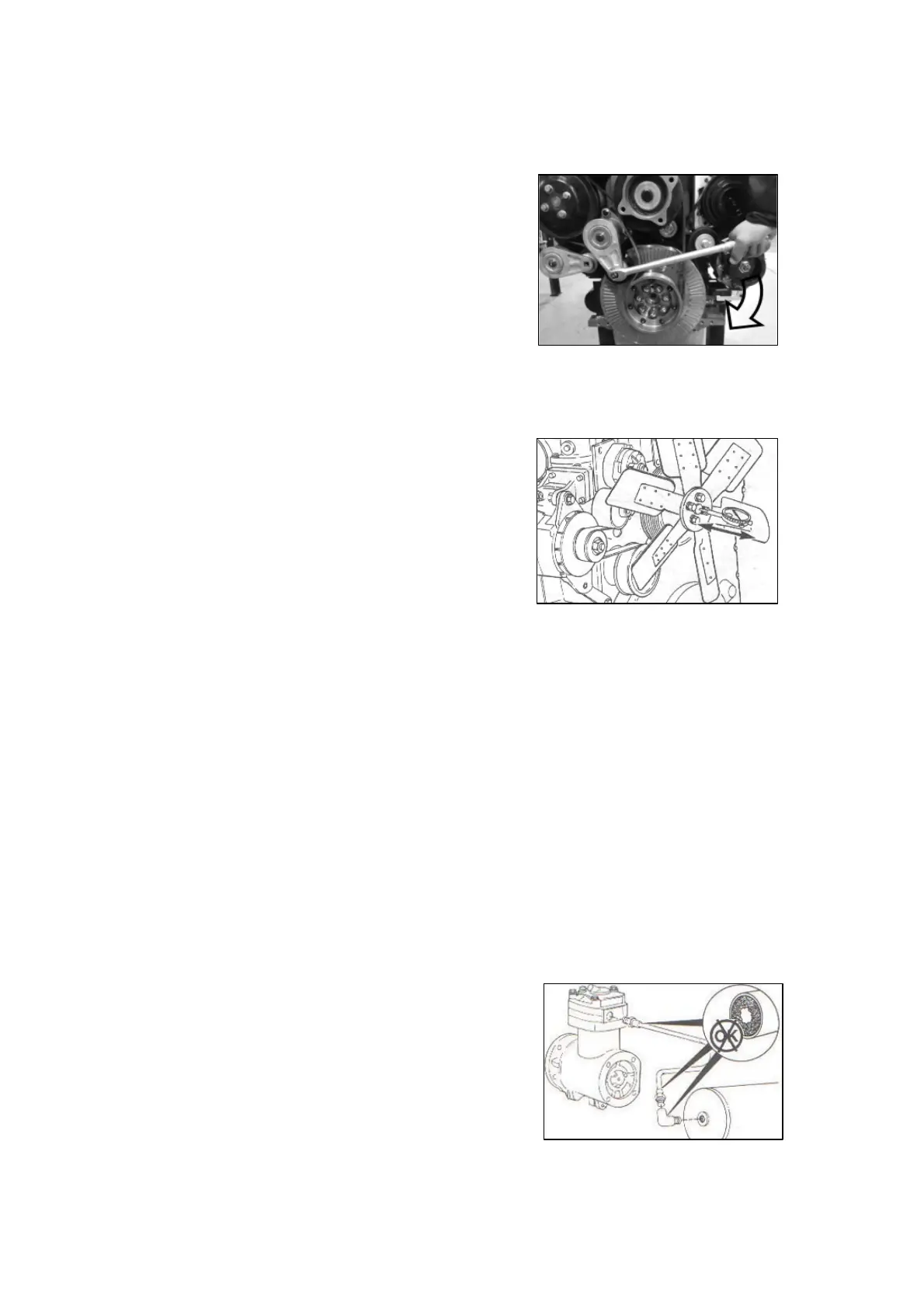

Rotate the belt tensioner clockwise and remove the drive

belt. Turn the fan to check the fan bearing for normality.

When rotating the fan, there should be no vibration or

excessive axial movement. Change the fan hub when

necessary.

(1) Rotate the belt tensioner clockwise, and remove the

drive belt. Turn the tensioner pulley to check it for seizure

or radial/axial movement, by which to determine if there is

scratch or wear on the bearing surface of the tensioner

pulley. Swing the tensioner arm to check if the spring

performs well.

(2) Install the drive belt and make a visual inspection after

the installation to make sure that the belt center line is in

alignment with the center lines of the pulleys.

Air outlet pipe

Check the air outlet pipe and joints for carbon deposit.

Clean or replace relevant parts based on the deposit.

Loading...

Loading...