11

GB

IMAT PT- E

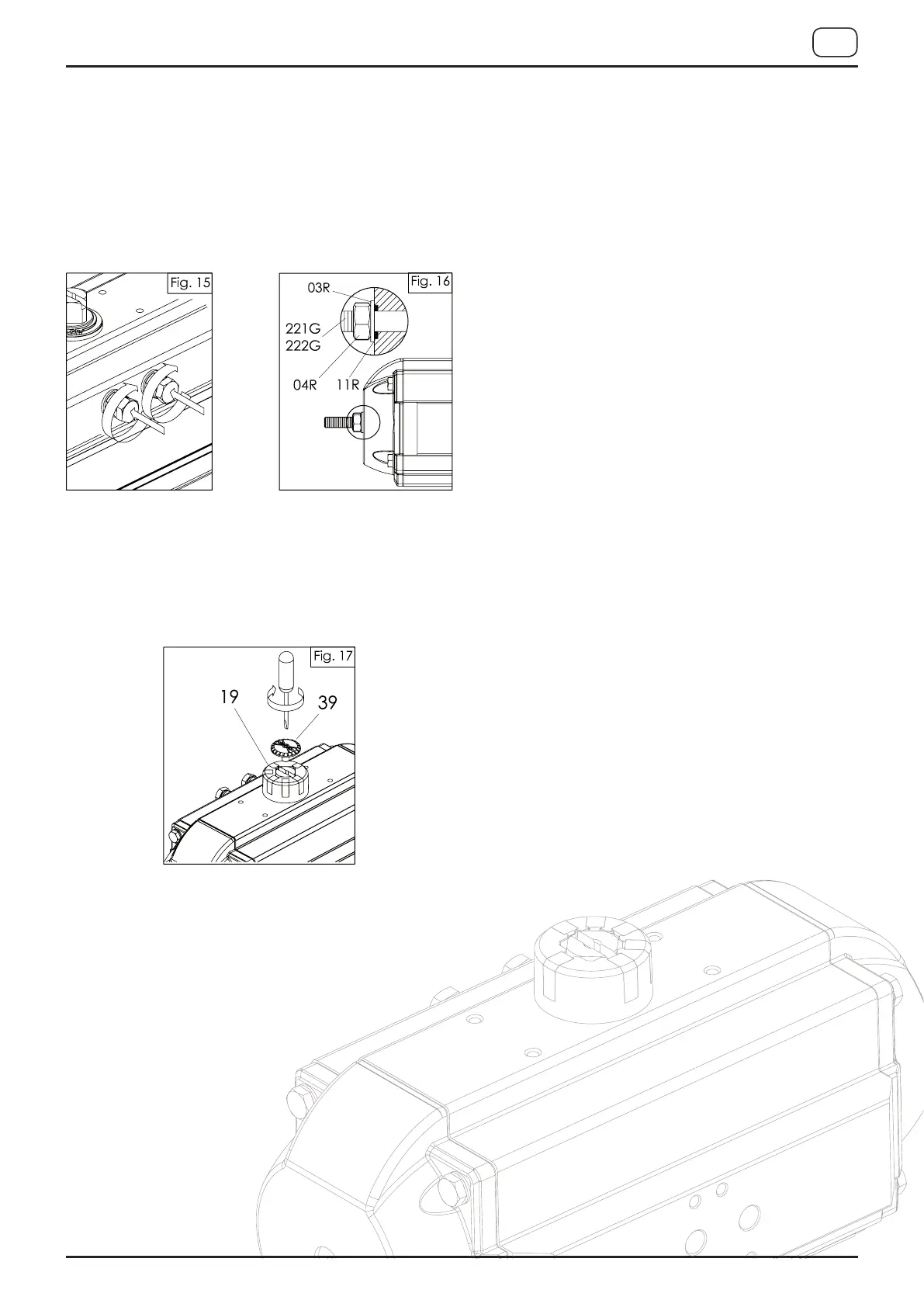

• Only for actuators with adjustment 50% or 100%, fi t

on end-cap adjustment screws 221G/222G the o-rings

11R, the washers 03R and the nuts 04R.

To adjust the stroke in open position: with the actuator

in partially or totally open position, screw or unscrew

the end-cap adjustment screw 221G/222G until the de-

sired position is achieved. It is important that the two

end-cap adjustment screws are both in contact with the

pistons. Then lock the nuts 04R.

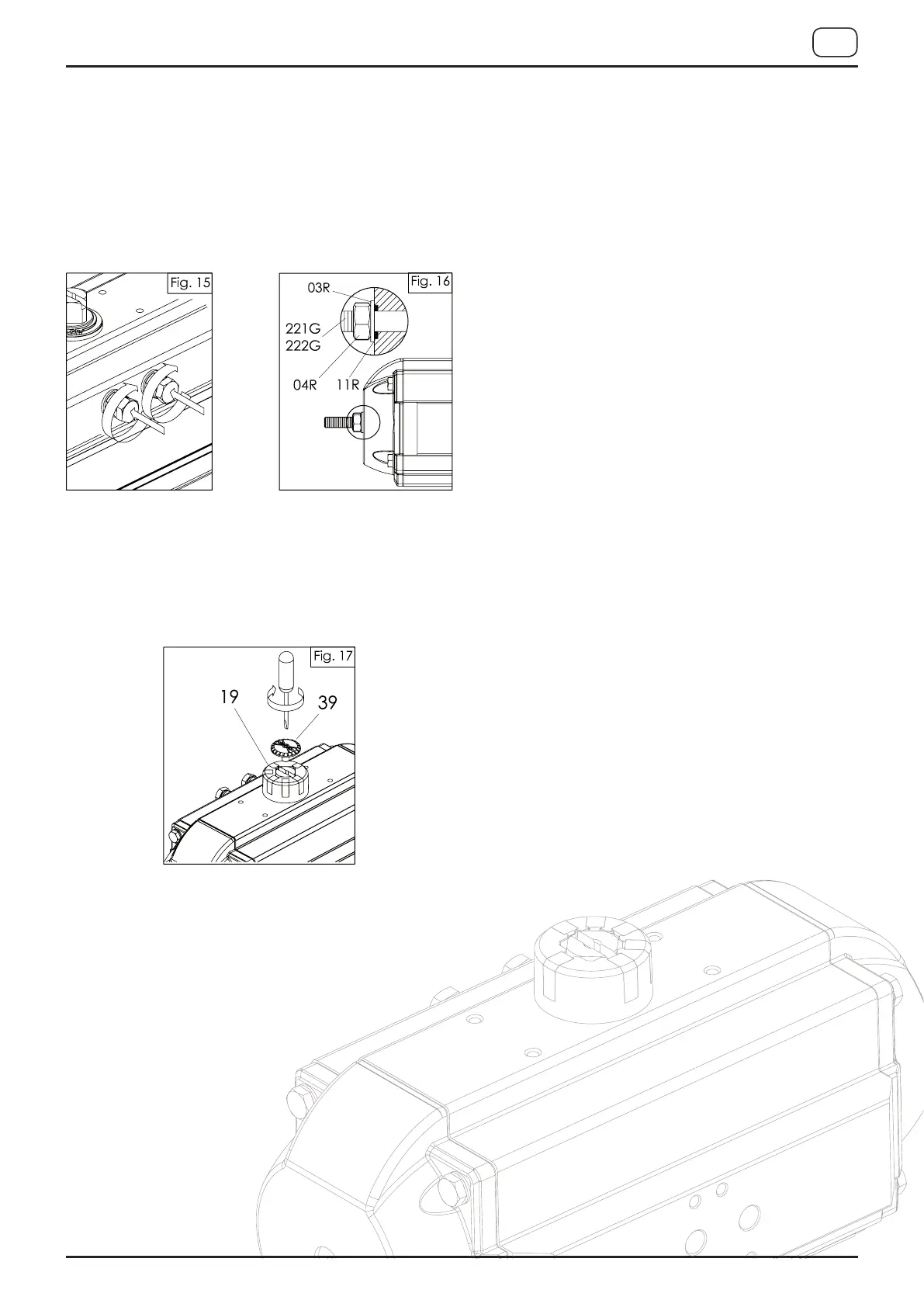

E) Assembly of graduated ring and position indicator

(Part N° 19), fi gures 17:

• Insert the indicator (19) making sure that it indicates the

correct actuator position.

• Screw the indicator screw (39, 39.1, 39.2) if assembled.

7) STORAGE INSTRUCTIONS

If the actuator is not for immediate use, the following

precaution must be taken for storage:

• Store the actuator in a clean and dry environment and at

temperature between -20°C (-4°F) and +40°C (+104°F).

• It is recommended that the actuator be stored in its orig-

inal box.

• Do not remove the plastic plugs on air supply ports

8) LIFTING and HANDLING

It is recommended to lift the actuators with proper, ad-

equate and permitted systems in relation to the actuator

weight and by following the ruling laws in terms of safety

and health protection. The weight of the actuators is in-

dicated on the Air Torque catalogue and on the related

technical data-sheets.

During the lifting and the handling of the actuators, it is

recommended to avoid clashes and/or accidental falls in

order to avoid irreparable damages to the actuators and

to compromise the functionality.

Contact Air Torque for any information and technical

data-sheets.

Loading...

Loading...