5

GB

IMAT PT- E

• For spring return actuators, avoid that dangerous and/

or corrosive substances in the working environment en-

ter into the external chambers by using adequate filters

and/or solenoid valves.

• Remove plugs from actuator air connections during in-

stallation and operation. Protect the air connections of

actuators not being used immediately.

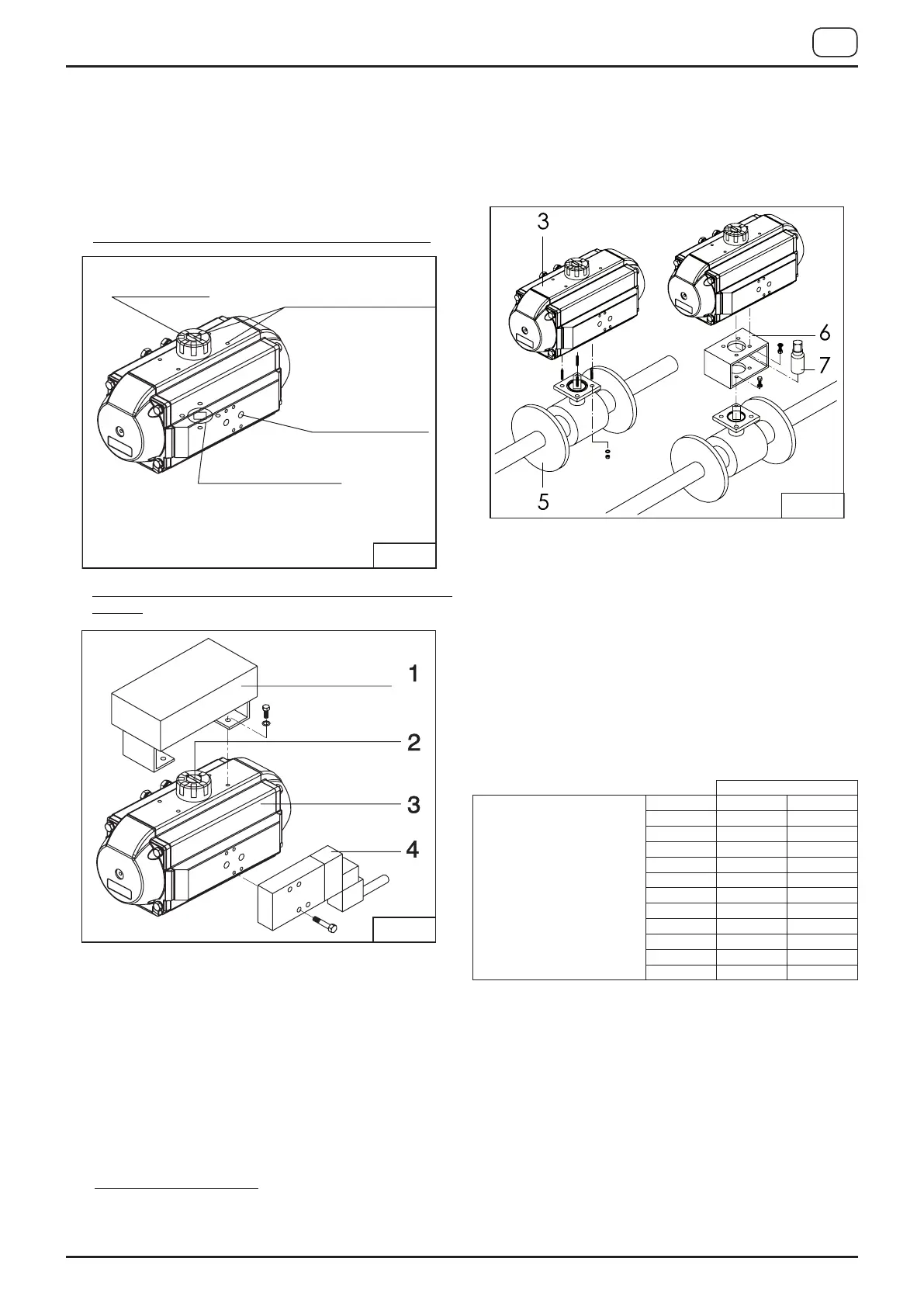

5.2) Interfaces for actuator controls and connections, Fig. A:

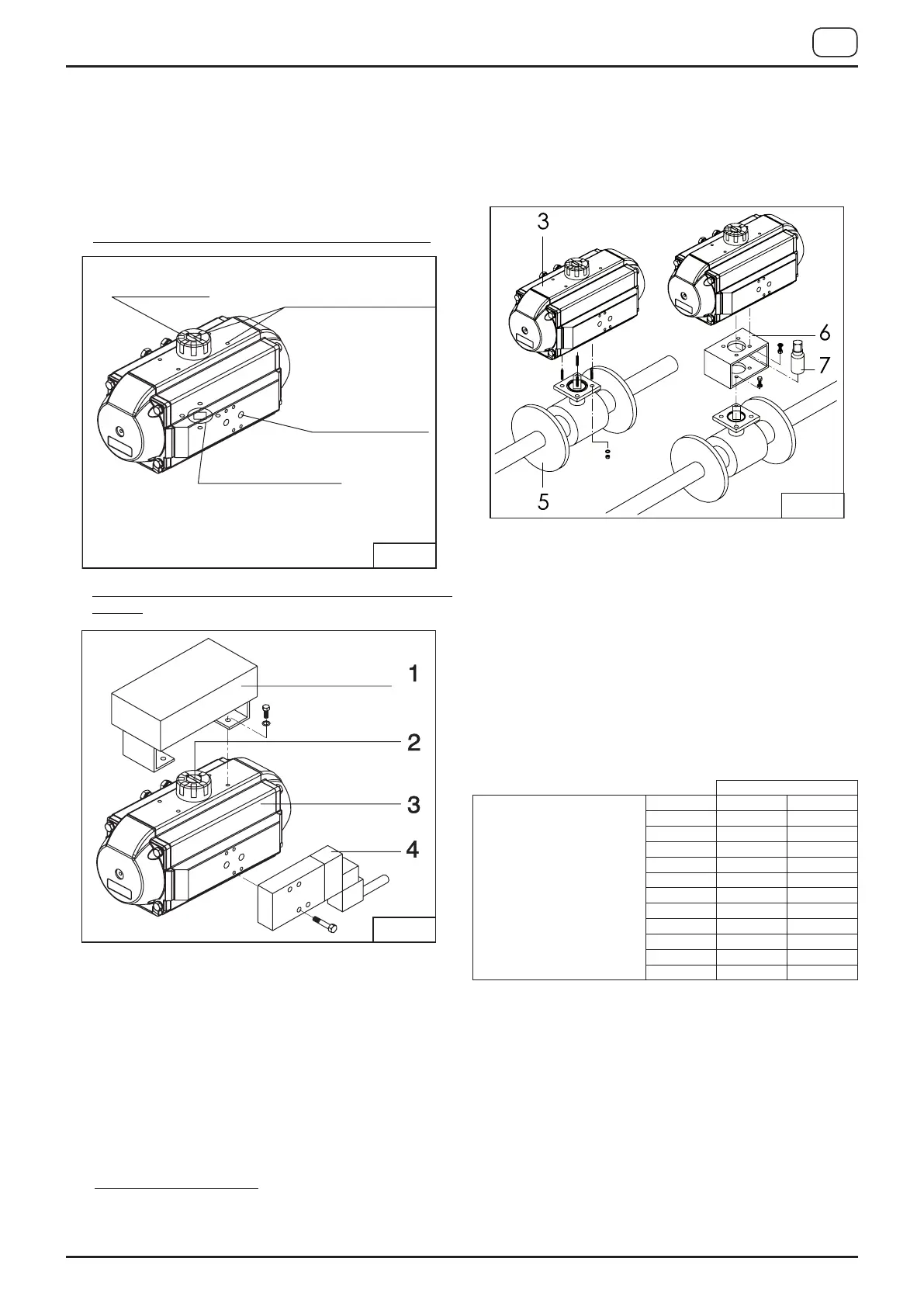

5.3) Assembly of accessories: solenoid valves and switchboxes,

figure B:

• Solenoid valve mounting:

Before mounting a solenoid valve, ensure that the actuator is

in its normal position (closed position) with pistons inwards.

For standard rotation type “ST” (clockwise to close) as-

sembly: the groove on the drive shaft or on the position

indicator 2 must be horizontal to the longitudinal axis of

the actuator in closed position.

Fit the solenoid valve 4 onto the actuator 3 using the pro-

vided screws (max. tightening torque see table).

• Switchbox mounting:

Fit the switchbox and bracket 1 onto the actuator 3 using

four provided screws (max. tightening torque see table).

5.4) Assembly of Valve Fig. C:

Before installing the actuator onto a valve, verify that the

maximum transmissible torque for available ISO Flange and

drive shaft connection is not exceeded according to ISO

5211 considering: the maximum actuator output torque,

the maximum air supply pressure and the maximum valve

torque. Before proceeding with the assembly of the actua-

tor onto the valve, be sure that the actuator operates in

the desired direction of rotation when pressurised and both

actuator / valve are in the correct position.

Important: when using a spring return actuator for a fail

safe operation, ensure that when air or electricity failure oc-

curs the direction of rotation is correct for your application.

Fit the actuator 3 onto the valve 5. It is possible to assem-

ble the valve onto the actuator in two ways:

•

Direct-mount: fit the stem of the valve 5 directly into the fe-

male connection of the actuator 3 and bolt together through

the valve ISO pad (max. tightening torque see table).

•

Bracket-mount: mounting with a bracket 6 and coupling 7,

the bracket is bolted to the actuator / valve to join them to-

gether and the coupling is used to connect the actuator out-

put drive to the valve stem (max. tightening torque see table).

6) MAINTENANCE INSTRUCTION

With the information given below, AIR TORQUE provides

the end user with all the required information necessary

for maintenance. Under normal conditions, the actuator re-

quires only periodic observation to ensure proper operation.

Maintenance (disassembly, maintenance and rebuilding) of

AIR TORQUE actuators is allowed only to AIR TORQUE

personnel or properly instructed personnel. In case of con-

troversy the product guarantee will expire! Spare kits for

maintenace are available to replace all seals and bearings

(soft parts indicated into the table), that may be necessary

between 200.000 and 1.000.000 cycles depending on oper-

ating and environmental conditions and actuator size.

Position indicator

VDI/VDE 3845

Pressure connections

VDI/VDE 3845

Ancillaries attachment

ISO 5211/ DIN 3337

Valve actuator attachment

Nm

Tightening torque table for

DRY (A) and LUBRICATED (B)

condition.

M… A B

M5 5 ÷ 6 4 ÷ 5

M6 10 ÷ 11 7 ÷ 8

M8 23 ÷ 25 18 ÷ 20

M10 48 ÷ 52 34 ÷ 36

M12 82 ÷ 86 60 ÷ 64

M14 132 ÷ 138 96 ÷ 102

M16 200 ÷ 210 150 ÷ 160

M20 390 ÷ 410 290 ÷ 310

M24 675 ÷ 705 500 ÷ 530

M30 (A.. 50) 620 ÷ 650 470 ÷ 500

M30 (A.. 70) 1340 ÷ 1400 1000 ÷ 1050

Loading...

Loading...