Maintenance

8-10 Flying Cloud

Refer to the following table for wheel specications.

Wheel Specications

Size/Center Size

In Inches

Lug Pattern Model

14x6 / 4.5 5 23 ft. Models only

15x6 / 5 6 All others

All wheels have zero offset.

Lug Nut Torquing

NOTE

Use a torque wrench to tighten lug nuts.

Tightening by hand or with an impact wrench is not

recommended. See the Specication Chart in this

manual for wheel torque ratings.

Trailer wheels must carry much higher loads per wheel

than passenger car or truck wheels. Each wheel may

carry 1000 pounds and higher. Furthermore, wheels on

tandem axle trailers do not steer, and are subjected to

very high side load stress whenever the trailer makes

a tight turn. When going around corners, especially on

slow, tight turns, the wheels are subject to very strong

side loads. This tends to ex the wheel and gradually

loosen the wheel nuts. Although the materials and

manufacturing methods are maximized for this kind of

service, these extra loads can cause stress, which can

result in exing and loosening of wheel nuts.

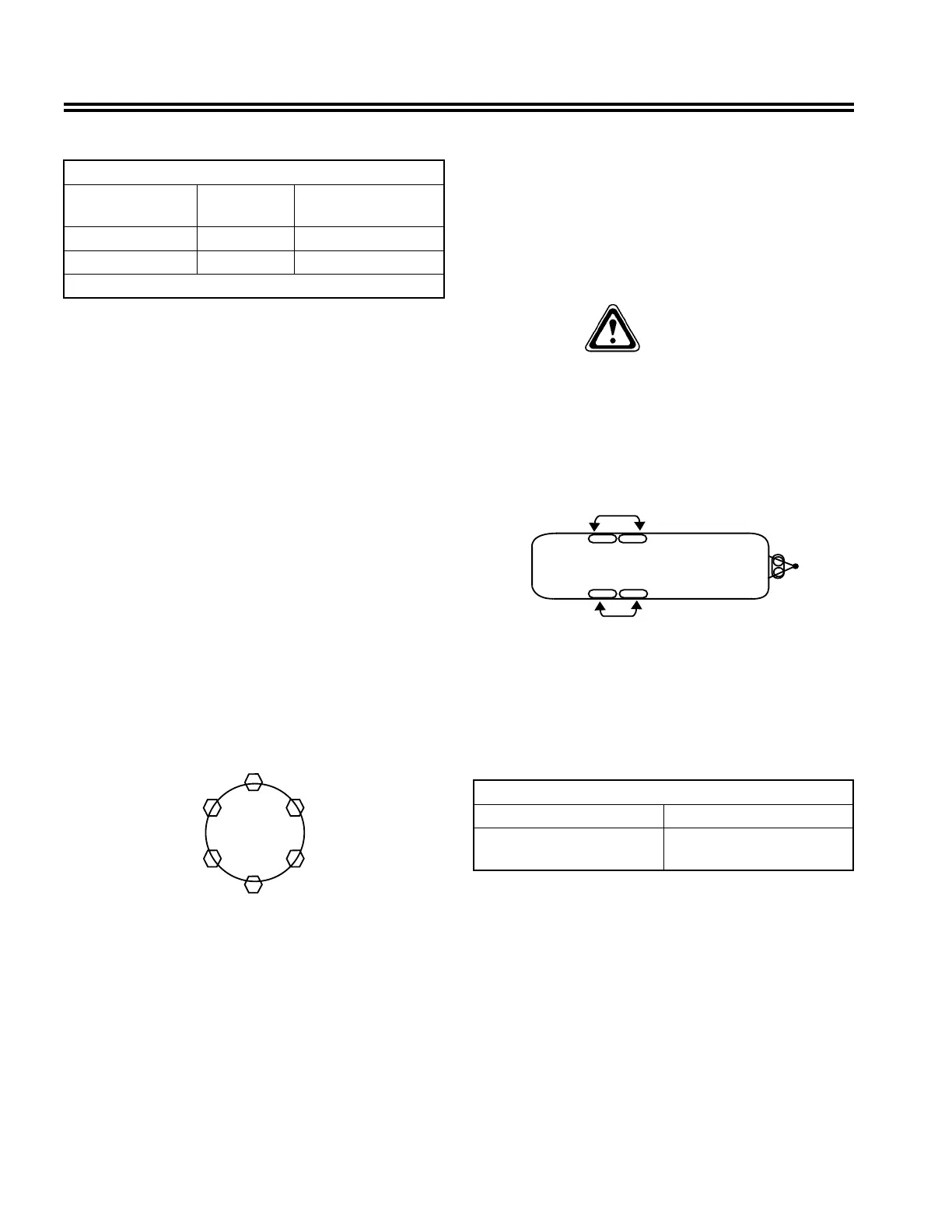

Before each trip and any time a wheel is replaced, be

sure to tighten the wheel nuts, following one of the

lug-pattern sequences shown below. If the wheel was

replaced, check the torque every 10, 25, and 50 miles.

1

2

3

4

6

5

If you notice wheel wobbling, or hear a rattling sound

coming from a wheel, especially at low speeds, a

wheel lug nut may have come loose. This problem is

usually caused by improper tightening, or by faulty or

damaged lug bolt threads.

If suspicious of a loose lug nut, safely stop vehicle as

soon as possible. Put up warning devices. Remove the

lug caps and check the tightness of all the lug nuts.

Tighten all lug nuts to the specied torque, using a

torque wrench. If stud threads are damaged or faulty,

get professional service help.

Spare Tire Carrier

The spare tire for Airstreams is stored under the front

of the trailer. The front handle of the tire carrier is a 1

in. tube protruding out from under the front A-frame

on the curbside. It is secured by a bracket and bolt

along the inside of the A-frame rail. Removing the bolts

allows the front on the tire carrier to be lowered and the

spare tire to be removed.

WARNING

The spare tire carrier is designed to carry an

undamaged tire and rim assembly of the type and

size specied for the trailer. Never place a severely

damaged wheel assembly with a damaged partial

tire, or a rim only, in the carrier.

Tire Rotation

(10,000-mile intervals)

Radial Tires

Axles and Bearings

NOTE

Never allow heat to be applied to the axle tube

since the rubber providing the spring torsion

action will be severely damaged.

Rubber Torsion Axle Alignment Specications

Toe-In and Camber Specications

Toe-In each side 1/16 in. Tolerance 1/8 in. + or -

Camber each side 3/4

degrees positive

Tolerance 3/4 degrees +

or -

Nev-R-Lube Drums/Bearings

Wide-body trailers, 25 ft. and over, are equipped with

Nev-R-Lube bearings. Dexter’s Nev-R-Lube bearings

are comprised of opposed tapered roller bearing cones

sealed inside of a precision ground, one-piece double

cup arrangement. These bearings are designed with

a small amount of axial end-play. The end-play is

essential to the longevity of the bearings service life.

Loading...

Loading...