Yrittäjäntie 14, FI-27230 Lappi • tel. +358 0207 416 740 • fax +358 0207 416 743 • www.narvi.fi/en

6

EN

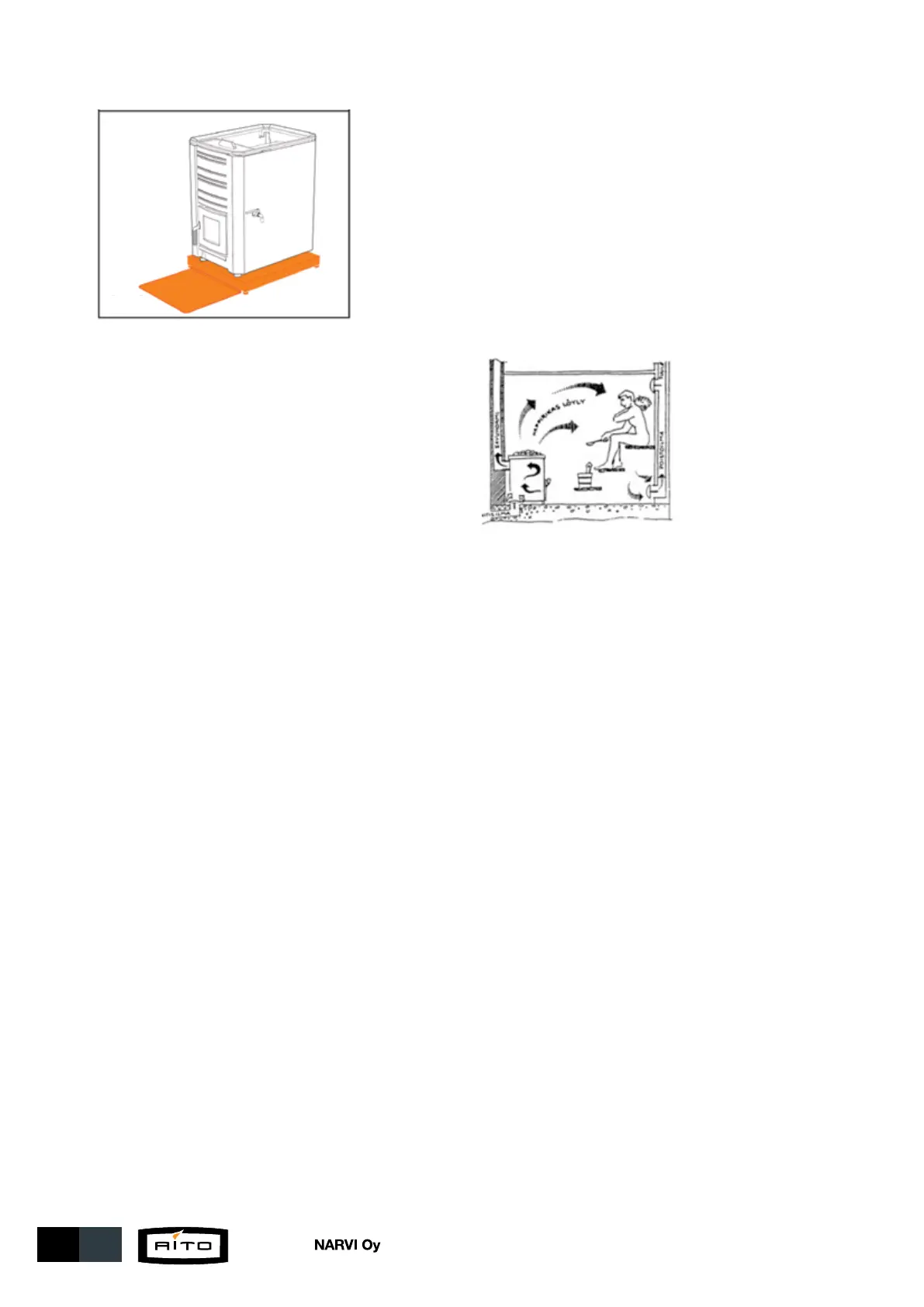

Protecting a floor made of combustible material

Figure 3. If the sauna heater is installed on a oor made of

combustible materials, an installation base must be used.

A piece of sheet metal must be installed in front of the in-

stallation base, which extends at least 100 mm over the

sides of the heater door and at least 400 mm in front of

the sauna heater. The sheet metal edges facing the sauna

heater must be turned up, so that coal cannot get under

the installation base.

Please observe that the safety clearance of an uninsu-

lated smoke ue from structures made of combustible

materials is 1000 mm or any other distance stipulated in

the manufacturer’s instructions.

2.3.2 Non-combustible structure

If the wall is masonry or other structure classied as non-

combustible, it is sufcient to have a 50 mm air gap be-

tween the upright surfaces and the wall.

2.4 Smoke flue

A smoke ue of the sauna heater must meet the require-

ments of class T600 irrelevant of the material of the smoke

ue. The minimum recommended draft of the smoke ue

is 12 Pa.

A modular smoke ue must meet the requirements of class

T600 and provided with CE-marking. When installing a

modular smoke ue safety clearances stipulated in the in-

stallation manual of the smoke ue shall be followed. The

minimum recommended diameter of a modular smoke ue

is 120 mm. The weight of the smoke ue must not cause

load on the sauna heater. The sauna heater should be con-

nected to a separate smoke ue. A smoke ue made of

bricks must be at least the so-called half-brick smoke ue.

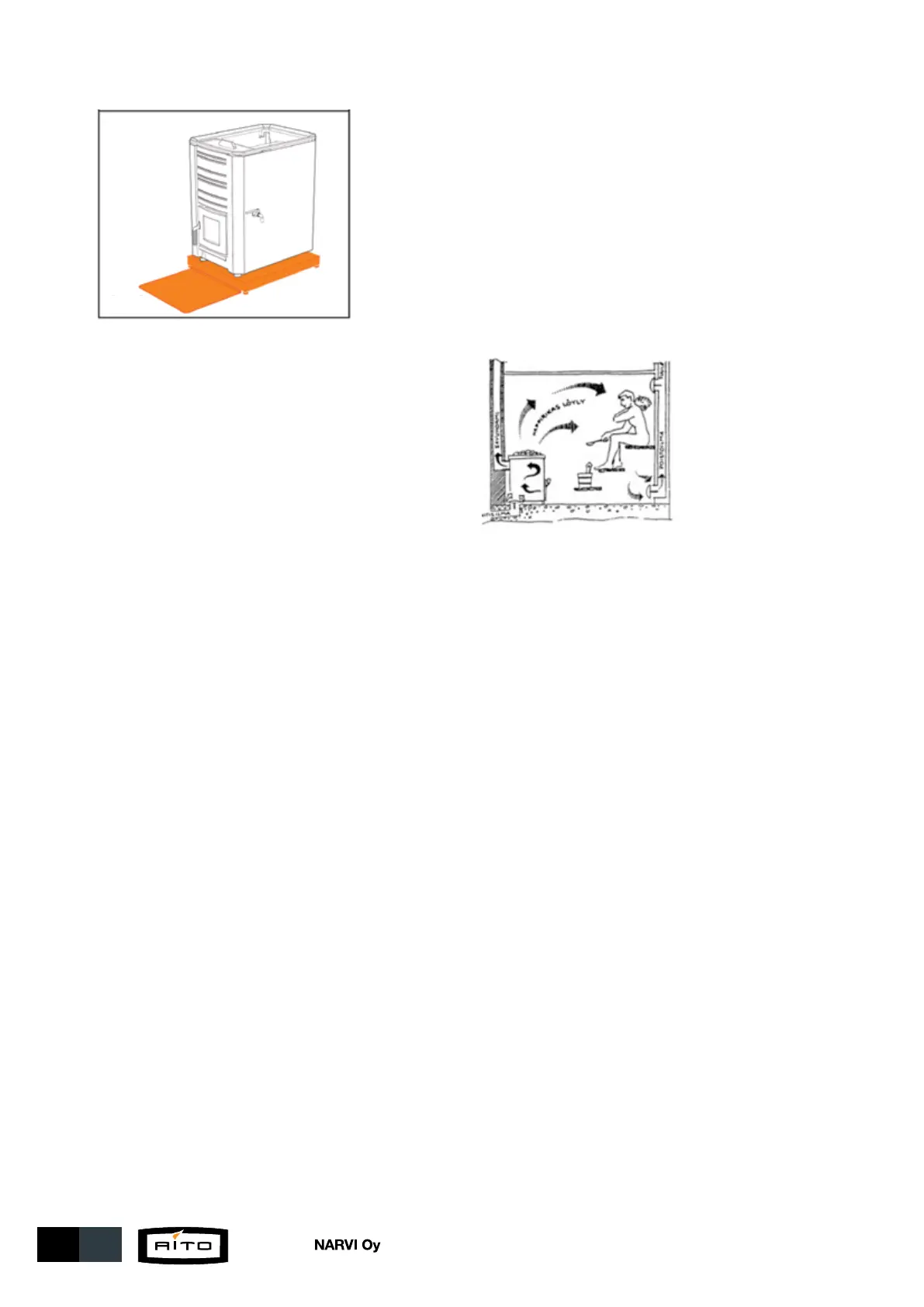

2.5 Ventilation

Ventilation of the steam room should be sufciently ef-

cient and should function so, that fresh incoming air

is routed as close to the sauna heater as possible. Also

proper air circulation has to be provided in the steam room

during using the sauna so that air can exit from under the

sauna bench or from under the door of the washing room

(sufcient gap).

Extraction fans working in the same room as the rebox

may cause problems. Inlets of incoming air should be lo-

cated so that they do not get blocked (for instance because

of snow). A rebox needs combustion air in a volume of

6–10 m

3

per kilo of red wood. The diameter of the ventila-

tion opening must be at least 100 mm. Forced air system

should be built according to the design prepared by the

designer of the heating, water and ventilation systems.

There shall be a possibility to ventilate sauna rooms after

using the sauna and to dry the rooms so that air will exit via

the upper part of the steam room.

Figure 3.

Loading...

Loading...