GB

Translation of original user instructions

10

AL-KO Lifting Support

Installation

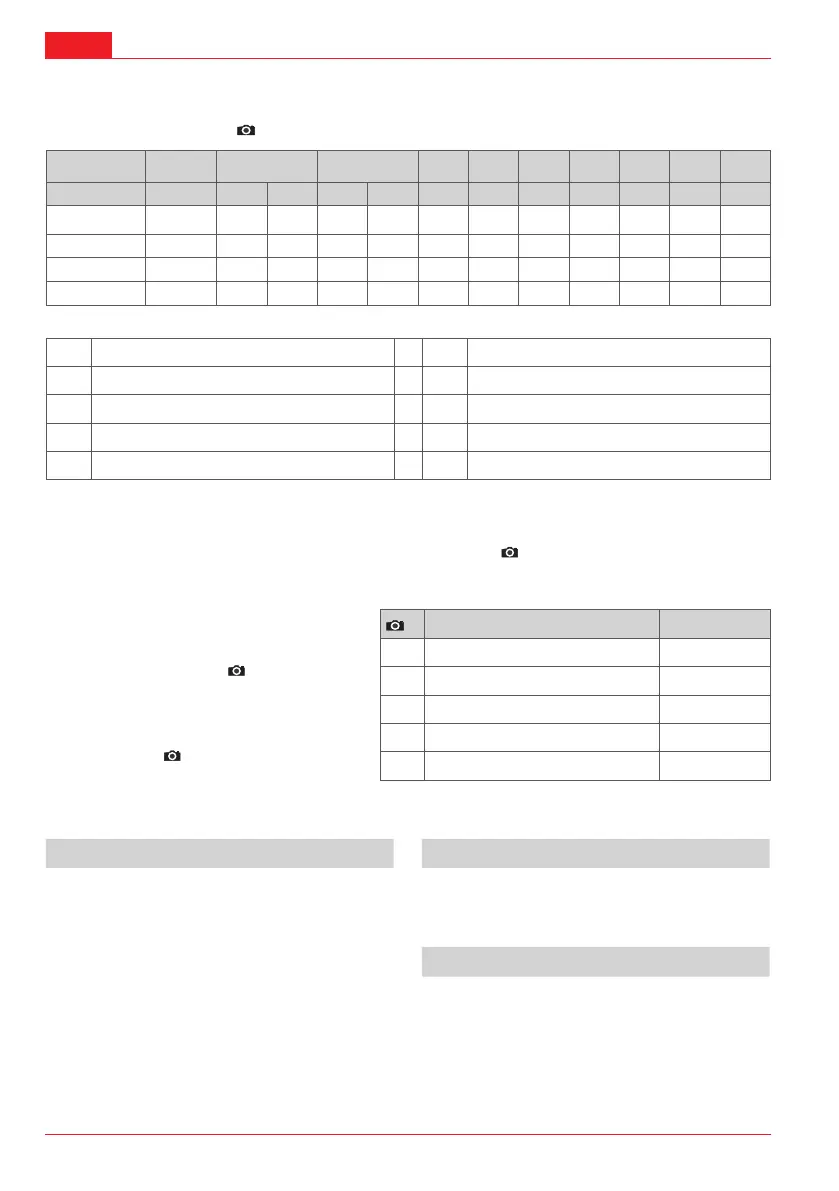

Installation dimensions - A

A B C D E F F

B

G H I M

min. max. min. max.

1239300/301 1239362 310 424 281 445 140 364 302 40 41.5 45 200

1239339/340 1239363 320 440 297 464 142 382 320 40 41.5 45 200

1239346/347 1239364 420 624 397 654 150 481 419 40 41.5 45 200

1239351/352 1239365 460 710 446 744 155 531 469 40 41.5 45 200

*

all dimensions in mm

A Order number for lifting support F Dimensions of support

B Order number for lifting support installation kit G Installation dimensions

C Required frame height H Installation dimensions

D Height of support I Installation dimensions

E Dimensions of support M Drive shaft length

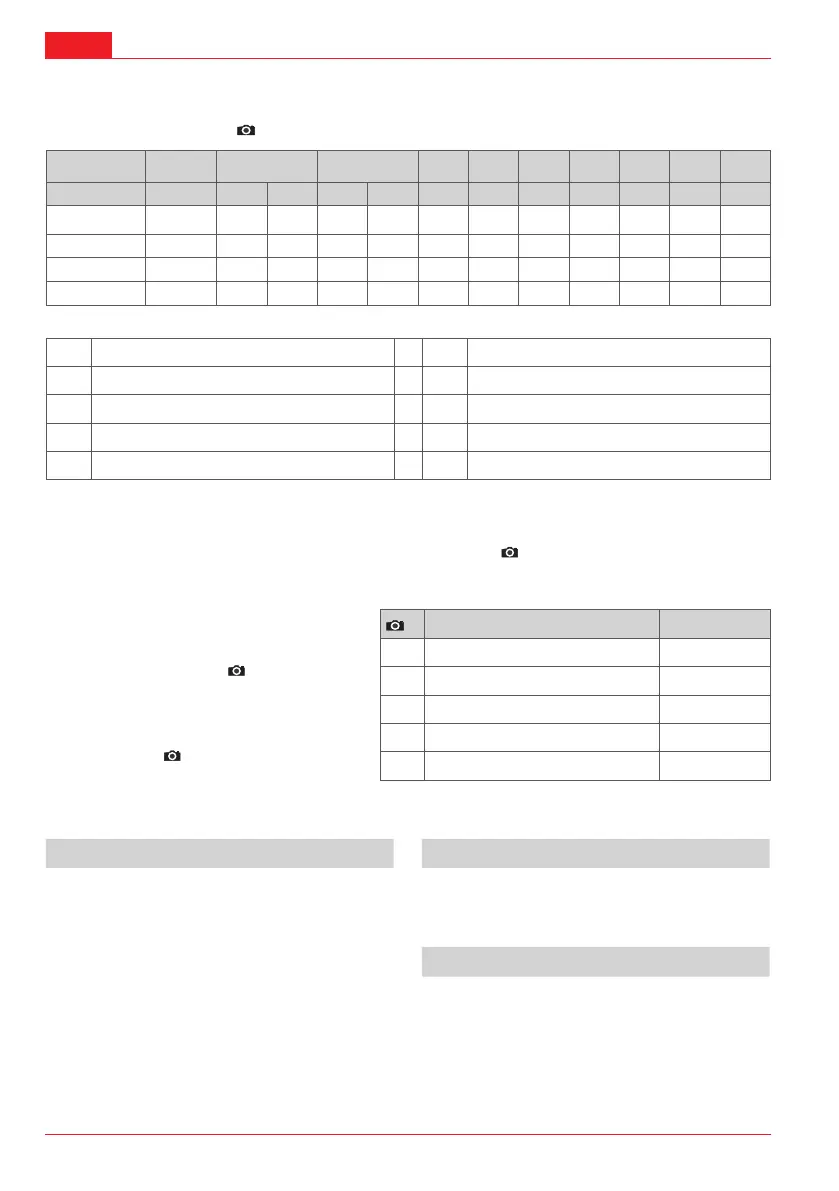

Installation variants

The lifting supports are screwed onto the frame in the specied positions ( A). Tightening torque: 45 - 50 Nm.

There are 2 different installation variants:

Installation variant A with collar knockouts

in the frame

Series installation (

2 -a)

2 Designation Quantity / side

1

Lifting support 1

2

Frame 1

Installation variant B without collar knock-

outs and holes in the frame

Retrot (

2 -b)

3

M10 hexagon nut (DIN 985-10) 2

4

Plate (604147) 1

5

Installation plate (1239370) 1

Operation

Before use Lowering the support

Apply the hand brake

On soft ground, use an appropriate base

On uneven ground, use chocks or levelling blocks

Avoid one-sided loading when lowering supports

Push on crank handle and turn in the direction indi-

cated by the arrow labelled “PARK”.

Retracting the support

Push on crank handle and turn in the direction indi-

cated by the arrow labelled “DRIVE”.

Loading...

Loading...