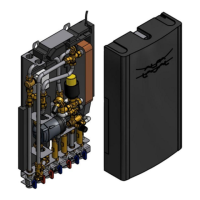

What to do if a flashing symbol appears on my Alfa Laval Micro STC Water Heater display after it's been running?

- NnicholaswellsAug 2, 2025

If a flashing symbol appears on the display of your Alfa Laval Water Heater after it has been operating for a while, it indicates that the heating appliance is showing an error. Press the button to see the error code. This fault code depends on the type of heating appliance.