Internally-mounted accessories are listed for field

installation under UL File E64983. Accessory instal-

lation should be done before the MCP is mounted

and connected. Refer to individual accessory

instruction leaflets.

To install the MCP, perform the following steps.

2-1. Make sure that the MCP is suitable for the intended

installation by comparing nameplate data with existing

ratings and system requirements. Inspect the MCP for

completeness, and check for damage before mounting.

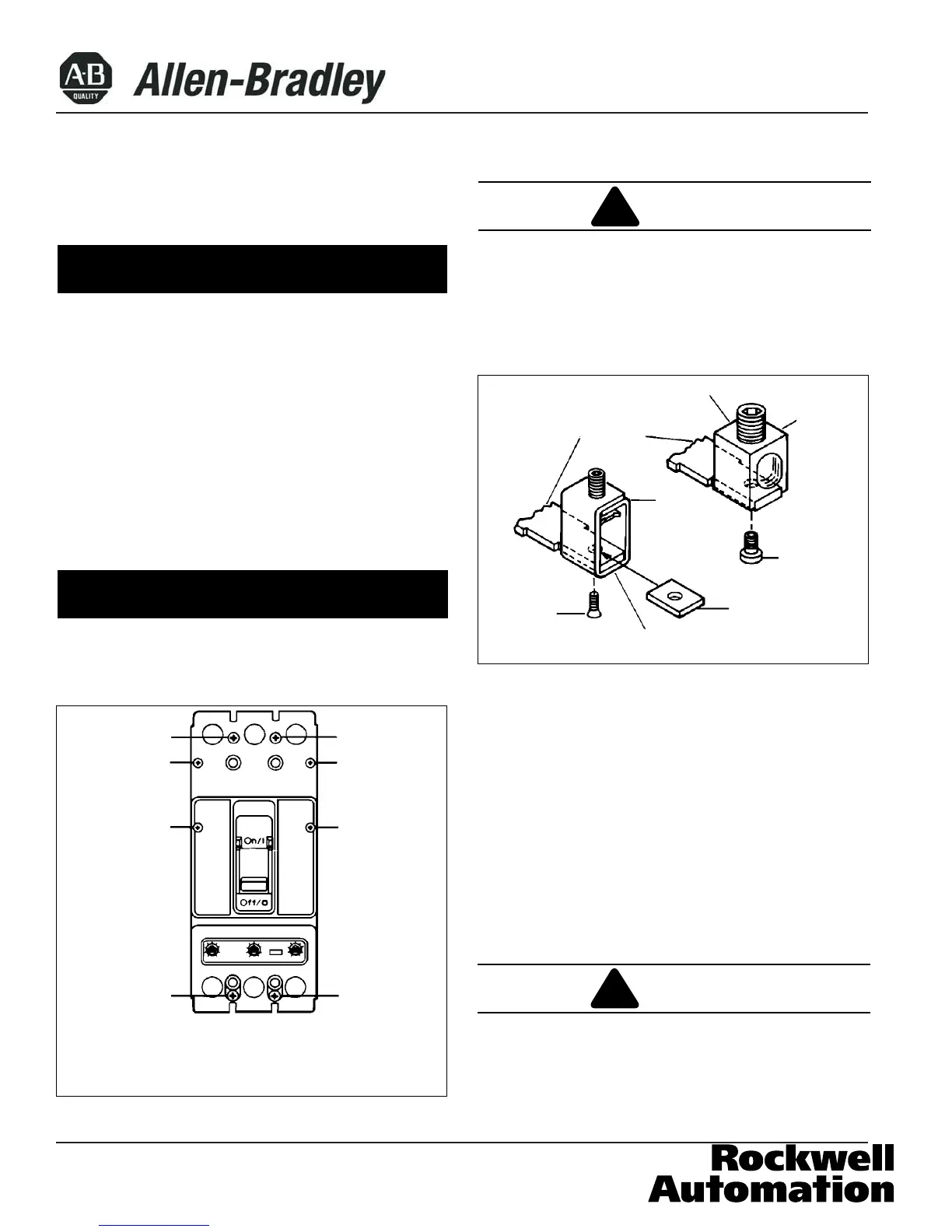

Perform Steps 2-2, 2-3, and 2-4 only if installation of

internal accessories is required.

2-2. Remove cover screws and cover.

2-3. Install accessories.

WHEN REMOVED AND REINSTALLED, THREAD-

FORMING SCREWS WILL TRY TO REFORM THE

THREADS IN THE BASE. CARE SHOULD BE TAKEN

EVERY TIME A THREAD-FORMING SCREW IS USED

TO ENSURE THE SCREW STARTS IN THE ORIGI-

NAL THREADS. DAMAGED THREADS CAN RESULT

IN IMPROPER MCP COVER RETENTION.

2-4. Install cover and secure with pan-head screws, fol-

lowed by thread-forming screws, as shown in Fig. 2-1.

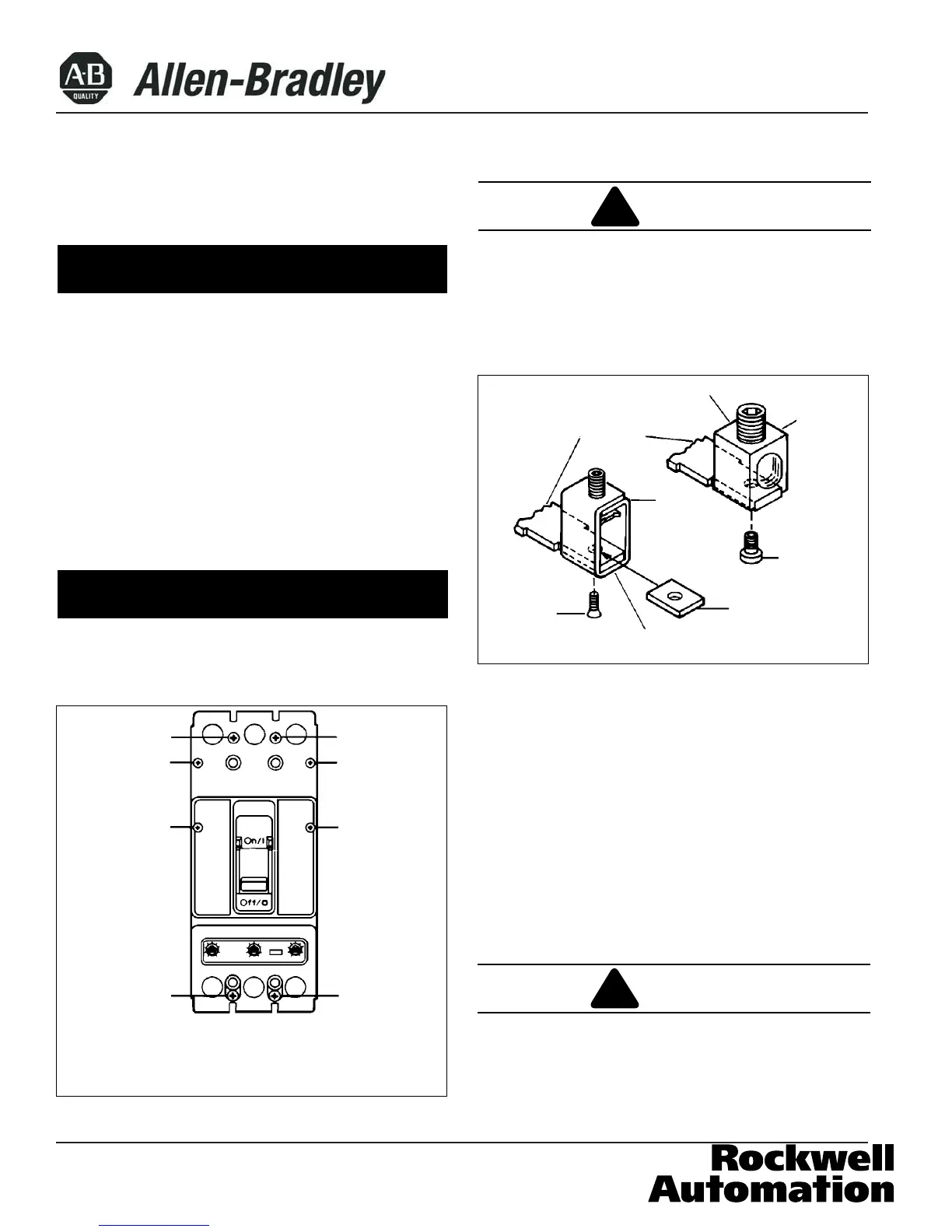

2-5. If not already installed, mount terminals as shown in

Fig. 2-2. When using aluminum body terminal (Catalog

No. TA250KB), secure the terminal to the MCP using a

1/8-inch socket wrench, and torque to 6-8 Ib-ft (8-11

N.m). After mounting the MCP and before installation of

the conductors, check or retighten the terminal mounting

screw through the terminal. Conductor securing screw

must be removed for this check. When using non-alu-

minum body terminal (Catalog No.T250KB), secure the

terminal to the MCP using screw and flat nut. Torque

the screw to 8-lb-in (1 N.m.).

THE VOLTAGES IN ENERGIZED EQUIPMENT CAN

CAUSE DEATH OR SEVERE PERSONAL INJURY.

BEFORE MOUNTING THE MCP IN AN ELECTRICAL

SYSTEM, MAKE SURE THERE IS NO VOLTAGE

PRESENT WHERE WORK IS TO BE PERFORMED.

40752-165(1) Effective March 2008

!

CAUTION

NOTICE

Also

Used

with

4-Pole

Circuit

Breaker

Figure 2-3 Cover Screw Installation Positions

① Screw, .190-32 x 3.13 Inch, Pan-Head, Cross-Recessed

➁ Screw, No. 8 x 1.88 Inch, Pan-Head, Cross-Recessed,

Thread Forming

①

①

①

①

➁

➁

➁

➁

!

WARNING

Figure 2-2 Terminal Installation

TA250KB Terminal

Terminal

Connectors

Collar

Socket

Screw

Collar

Nut

T250KB Terminal

Flat Head

Screw

NOTICE

Page 2

Loading...

Loading...