Allied Construction Products, LLC www.alliedcp.com

SOM576701_14jan

45

14.0 Technical Information –[cont’d]

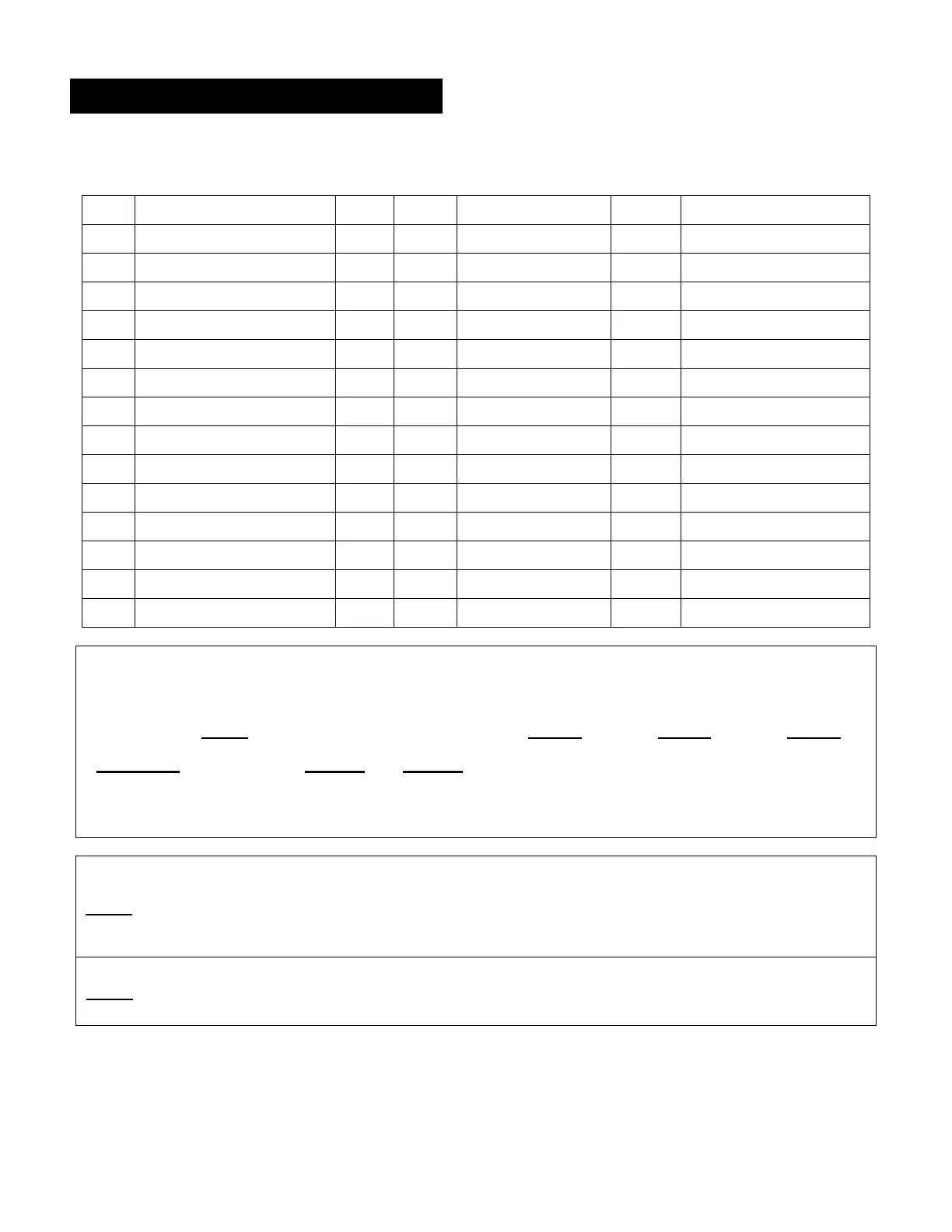

Table 14.4 Fastener Torque Model AR110C AR120B

Item Description Qty Size Ft-Lbs. [N·m] Size Ft-Lbs. [N·m]

9 Accum Top Bolt 8 370 [500] 480 [650]

11* Side Rod (Torque + Turn) 4 --- 370 [500] + 100º --- 370 [500] + 100º

43 Accum Bottom Bolt 12 M20 260 [350] M22 390 [530]

44 Gas Charge Bolt 1 M08 15 [20] M08 15 [20]

45 Flg Mtg Bolt [OUT] 4 M12 70 [130] M14 110 [150]

47 Flg Mtg Bolt [IN] 4 M10 45 [60] M12 70 [130]

48 Flg Plug 3 R1/4 24 [33] R1/4 24 [33]

49 Main Spool Cover Bolt 12 M14 175 [240] M16 103 [140]

53 Oper Valve Cover Bolt 4 M12 115 [160] M12 73 [100]

55 Flg Plug 1 R1/2 65 [90] R1/2 65 [90]

56 Flg Plug 2 R3/8 50 [70] R3/8 50 [70]

57 Flg Plug 1 R R

65 Check Valve Cover Bolt 4 M12 115 [160] M12 115 [160]

--- Top Mtg Brkt Bolts 14 M24 580 [800] M24 580 [800]

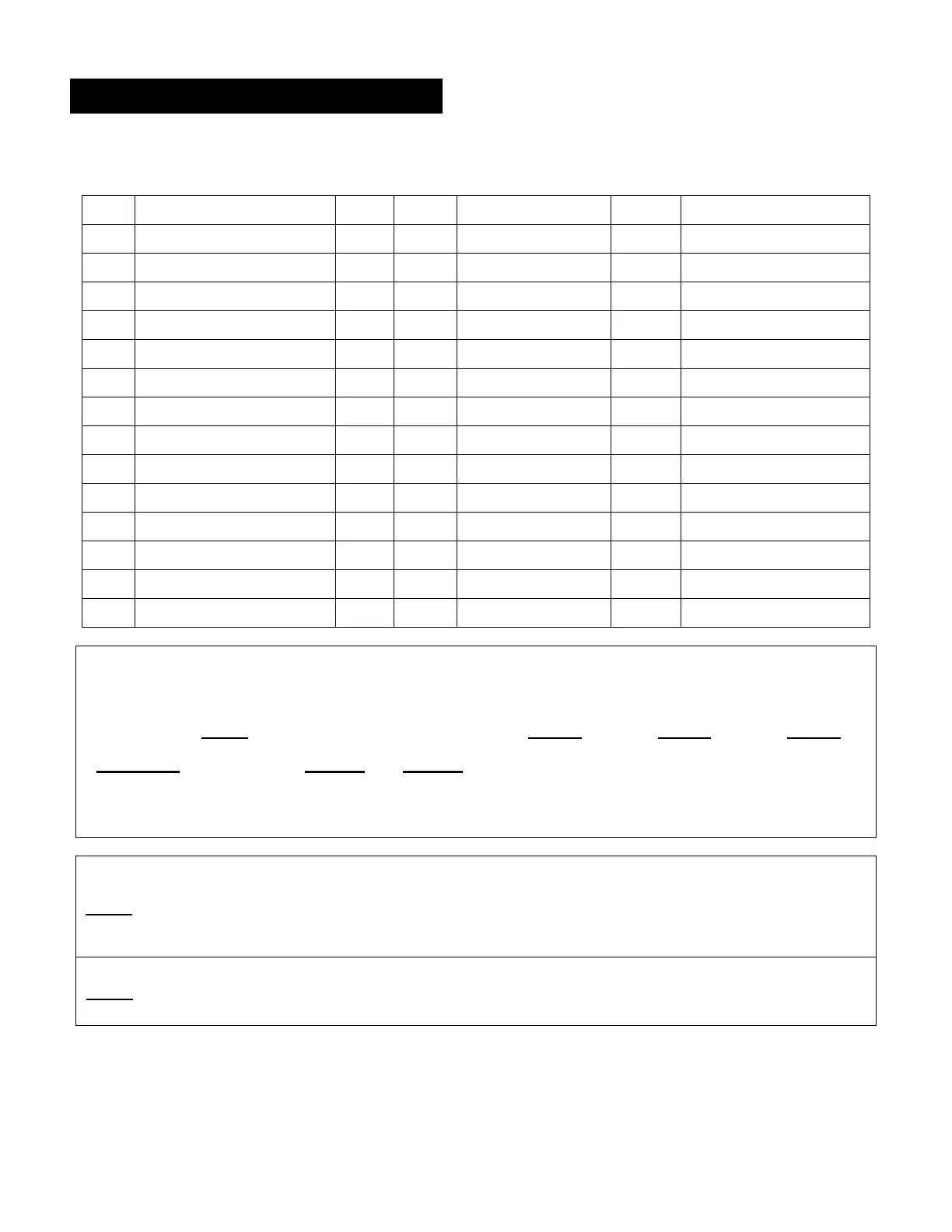

Table 14.5 Side Rod Tightening Item 11*

IMPORTANT! Apply Moly-Paste 676927 to threads before assembly.

Step 1 Level-1 Level-2 Level-3

Pre-torque Ft-Lbs. [N·m] AR110C AR120B

125 [165] 245 [330] 370 [500]

*Use progressive tightening technique to draw side rods up evenly. Torque the side rods* in diagonal

sequence (Fig 14-5), in small increments (Level 1, Level 2, Level 3), until torque level (3) is achieved.

Step 2

Apply heat evenly to

side rods

IMPORTANT! Do not over-heat the side rods. Excessive heat will

damage side rod beyond use. Do not exceed 390 F [200 C]. Heat until

side ride can be turned with hand wrench* and minimal effort applied. (*3/4"

drive and breaker bar)

Step 3

Final Torque + Turn º

Turn each side rod according to +º (or flats) shown in table. Follow

tightening sequence Fig 14-5. Use hand wrench only - Impact tools

prohibited!

Loading...

Loading...