Copyright © 1996 General Motors Corp. 6–27

REBUILD OF SUBASSEMBLIES

(6) Repeat Steps (2), (3), (4), and (5). When

the running clearance is within 0.0765–0.1265 inch

(1.944–3.213 mm), remove snapring 1, clutch back-

plate 2, clutch plates 3 and 4, and piston. Keep the

clutch plates together as a package until required.

c. Assembly (Foldout 9,A)

(1) If check ball 12 was removed, place the

new ball into the bore. Stake the bore at three equally

spaced locations. The bore is properly staked when the

ball has the minimum axial movement specified in Fig-

ure 6–45 and when the ball is retained by the staking

when a 30 lb (133 N) load is applied against the ball.

(2) Install sixteen return springs 7 (Foldout

9,A) into their pockets in piston 8. Install spring re-

tainer 6, recess side first, onto the springs.

(3) Place the clutch assembly in a press,

spring retainer upward. Lay snapring 5 in its approxi-

mate installed position, on spring retainer 6.

(4) Using compressor J 23616, compress the

spring retainer until it clears the snapring groove in the

housing hub (Figure 6–43). Install snapring 5 (Foldout

9,A) into the groove in the hub in clutch housing as-

sembly 11. Release the press and remove the clutch as-

sembly.

(5) Beginning with an external-tanged clutch

plate, install the clutch pack removed in Paragraph 6–

12b(6) or that which was determined in Paragraph 6–

17c.

(6) Install backplate 2, flat side first, onto the

clutch plates. Install snapring 1 to retain the backplate.

6–13. CENTER SUPPORT ASSEMBLY

a. Disassembly (Foldout 9,B)

(1) Remove pistons 9 and 18 with attached

parts, from center support assembly 13

(2) Remove eight retainer washers 6 and 21,

(Figure 6–46).

(3) Remove spring retainers 7 and 20 (Fold-

out 9,B). Remove twenty-four piston return springs 8

and 19.

(4) Remove piston sealrings 10 and 11 from

piston 9.

(5) Remove piston sealrings 16 and 17 from

piston 18.

(6) Remove the two hook-type sealrings 12

from center support and bushing assembly 13.

(7) Insert, but do not force, rotating sealring

gauge J 29198-1 into the hub sealring grooves. Rotate

the gauge 360 degrees. If the gauge will not rotate

freely, the front support must be replaced.

(8) If bushing replacement is necessary,

place support and bushing assembly 13 in a press,

sealring grooves side upward. Press bushing 14 out of

the support.

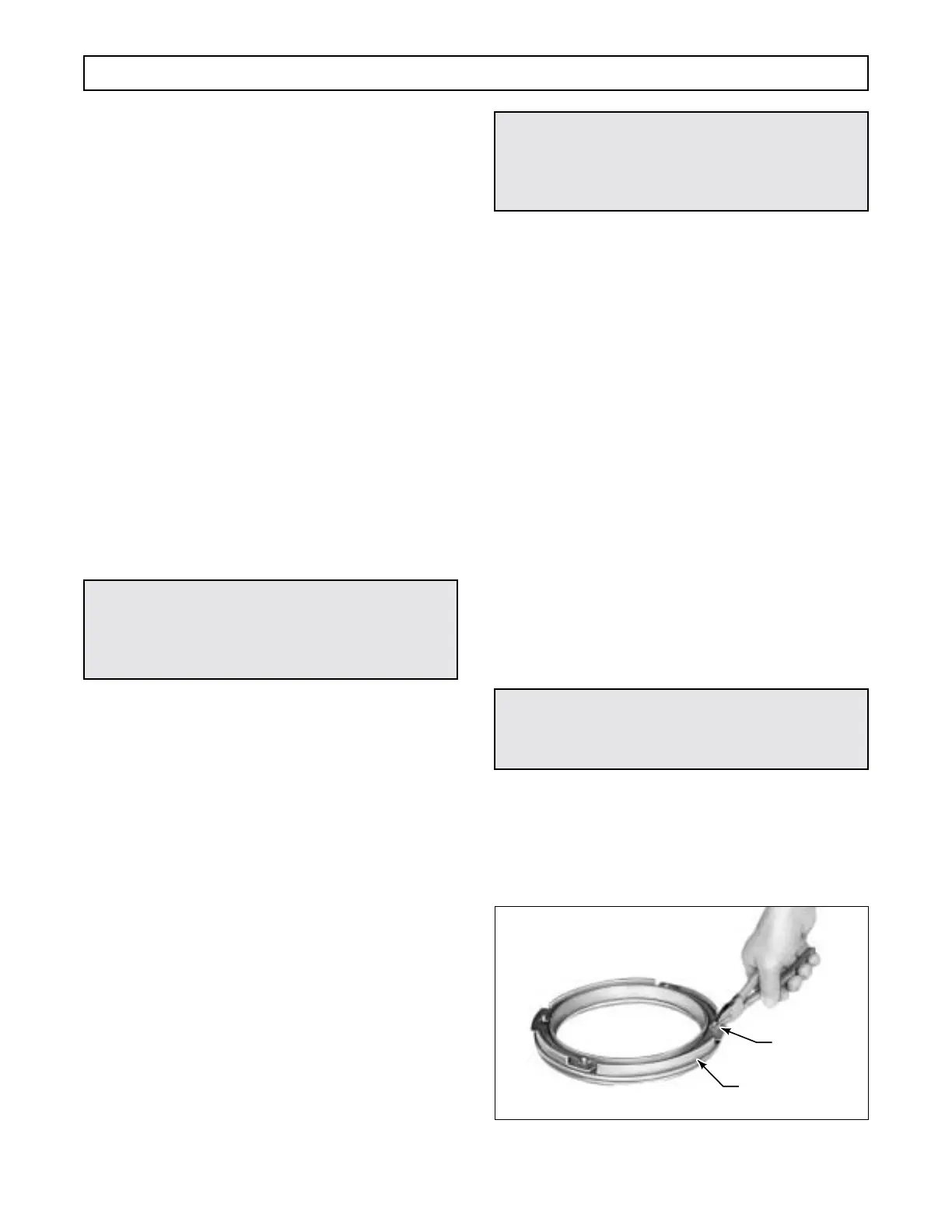

Figure 6–46. Removing Self-Locking Retainer Washers

CAUTION:

When installing the fourth clutch snapring, do

not allow the spring retainer to catch in the

snapring groove.

CAUTION:

When removing piston retainer washers, cut the

retainer washers carefully to prevent damaging

the piston projections.

CAUTION:

When removing the center support bushing be

careful not to damage the bushing bore.

THIRD CLUTCH

PISTON

RETAINER

WASHER

H02260

Loading...

Loading...