Copyright © 1996 General Motors Corp. 3–23

PREVENTIVE MAINTENANCE

PREVENTIVE MAINTENANCE

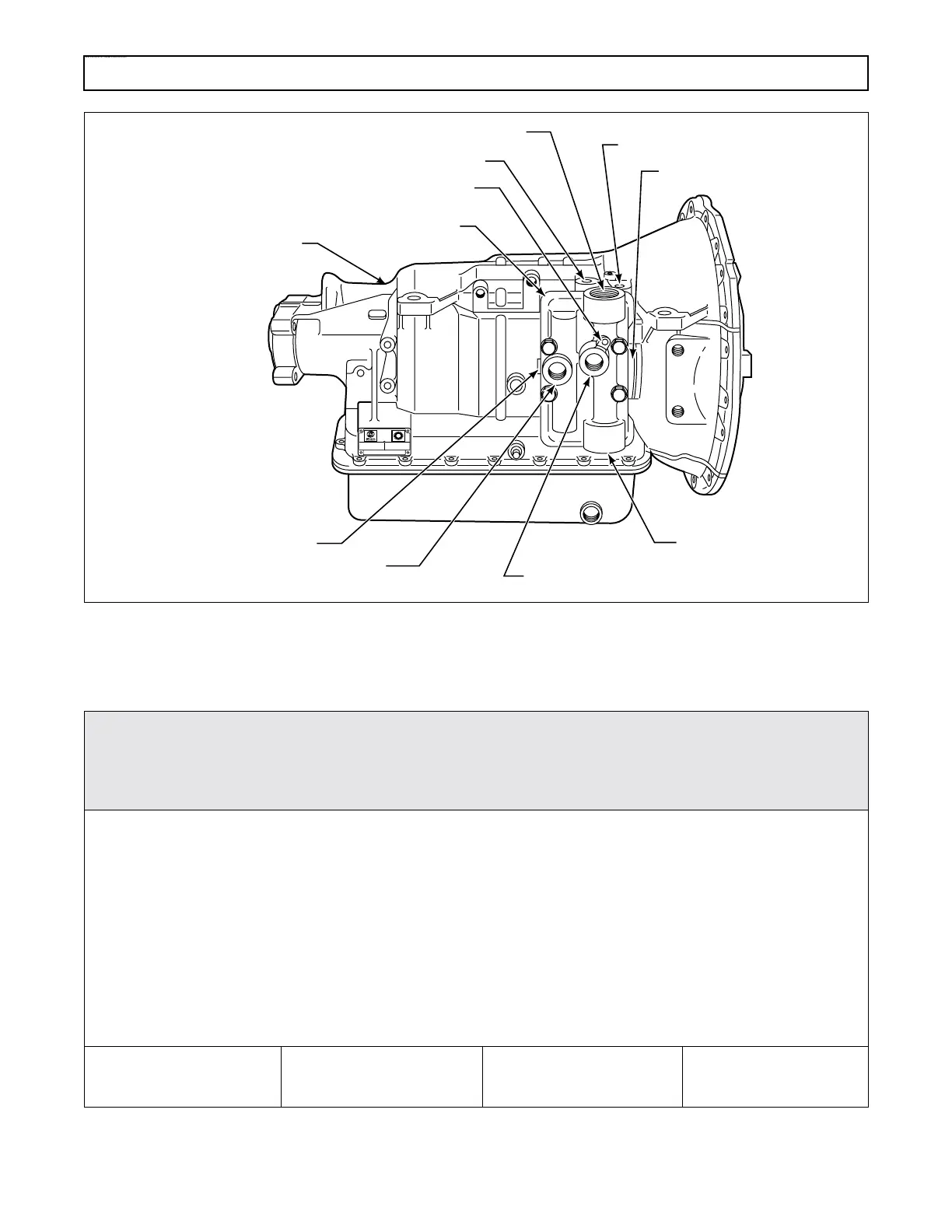

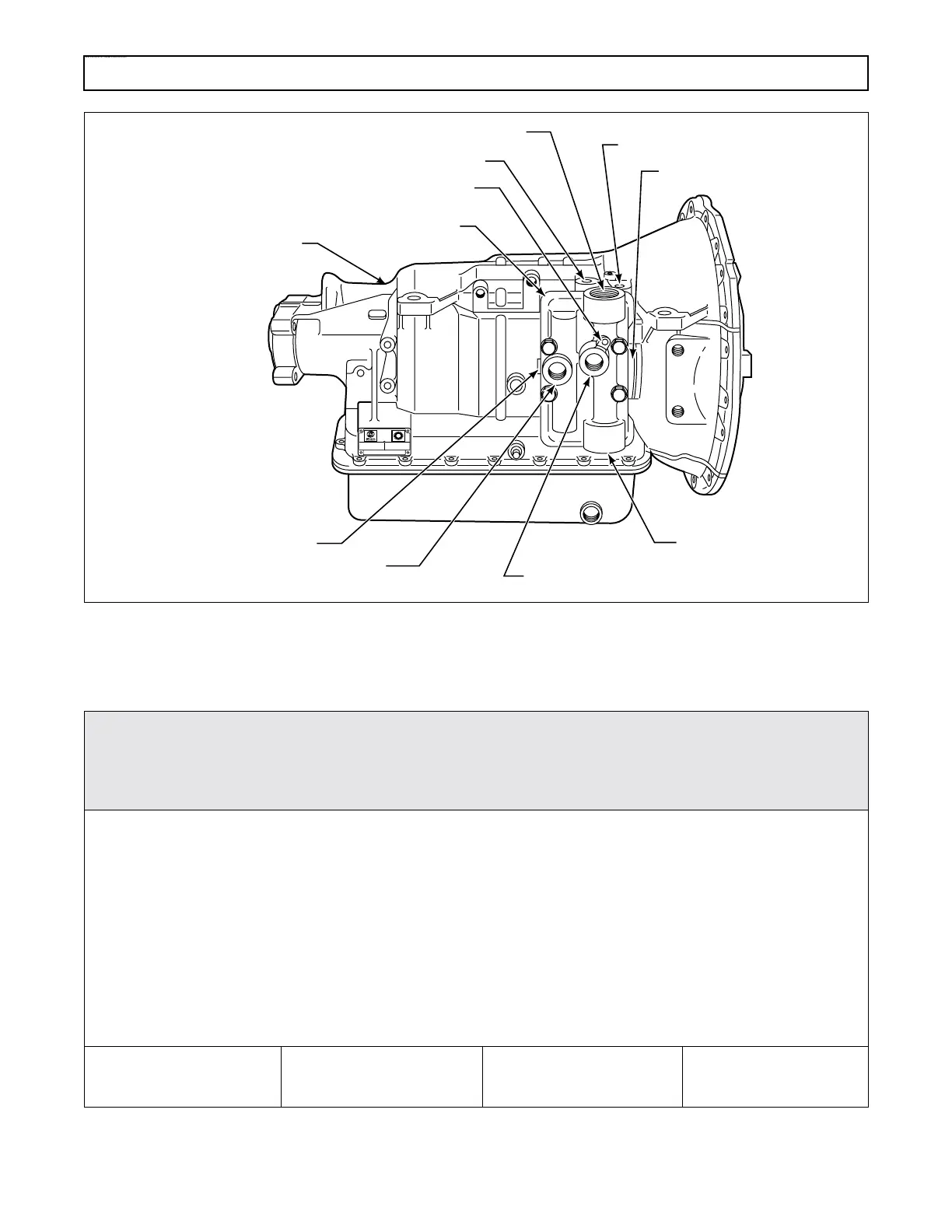

Figure 3–13. Transmission Check Points (Models With Retarder)

Table 3–10. Main Pressure Check Procedure

(Models With Demodulated Main Pressure)

WARNING!

Observe safety precautions during hydraulic pressure check procedures. All personnel must stand clear

of the vehicle. Take precautions against movement of the vehicle. Be sure that gauges (vacuum, pressure,

tachometer) have extended lines so that they can be read from inside the vehicle.

PROCEDURES:

(1) All transmission fluid level and pressure checks must be made at normal operating temperatures

(160–200°F (71–93°C) sump; 180–220˚F (82–104˚C) converter-out). Check transmission fluid

level.

(2) Connect 0–300 psi (0–2068 kPa) oil pressure gauge. Connect tachometer.

(3) Check Neutral and Forward pressures with engine running at 1200 rpm, brakes applied.

(4) Check Reverse pressure, with engine running at 2500 rpm, brakes applied. Reconnect driveline.

(5) Check Lockup pressures with transmission in third and fourth range, with engine at full throttle.

NEUTRAL 135-155 psi

(931–1068 kPa)

FORWARD 135–155 psi

(931–1068 kPa)

REVERSE 230–275 psi

(1586–1896 kPa)

LOCKUP 120 psi min

(827 kPa min)

E

C

A

P

S

O

R

E

A

E

L

I

B

O

M

O

T

U

A

D

E

T

I

N

U

A

C

I

R

E

M

A

F

O

S

R

E

K

R

O

W

T

N

E

M

E

L

P

M

I

L

A

R

U

T

L

U

C

I

R

G

A

D

N

A

UAW

933

DIVISION OF

GENERAL MOTORS

CORPORATION

INDIANAPOLIS

INDIANA

SERIAL NO.

XXXXX

XX XXXXX

XXXXXXX

MODEL

NO.

PART NO.

RETARDER VALVE BODY

FIRST CLUTCH PRESSURE TAP

(NEAR SPEEDOMETER PROVISION)

TRANSMISSION “FROM COOLER” PORT

FROM PRIMARY COOLER

TRANSMISSION “TO COOLER” PORT

WIRING HARNESS CONNECTOR

TO PRIMARY COOLER

TO SECONDARY COOLER

CONNECTS TO TRANSMISSION “MAIN” PRESSURE TAP

(OPPOSITE SIDE OF TRANSMISSION)

CONNECTS TO TRANSMISSION

“TO COOLER” PORT

TEMPERATURE SENDING UNIT

V02889

Loading...

Loading...