Copyright © 1996 General Motors Corp. 3–25

PREVENTIVE MAINTENANCE

PREVENTIVE MAINTENANCE

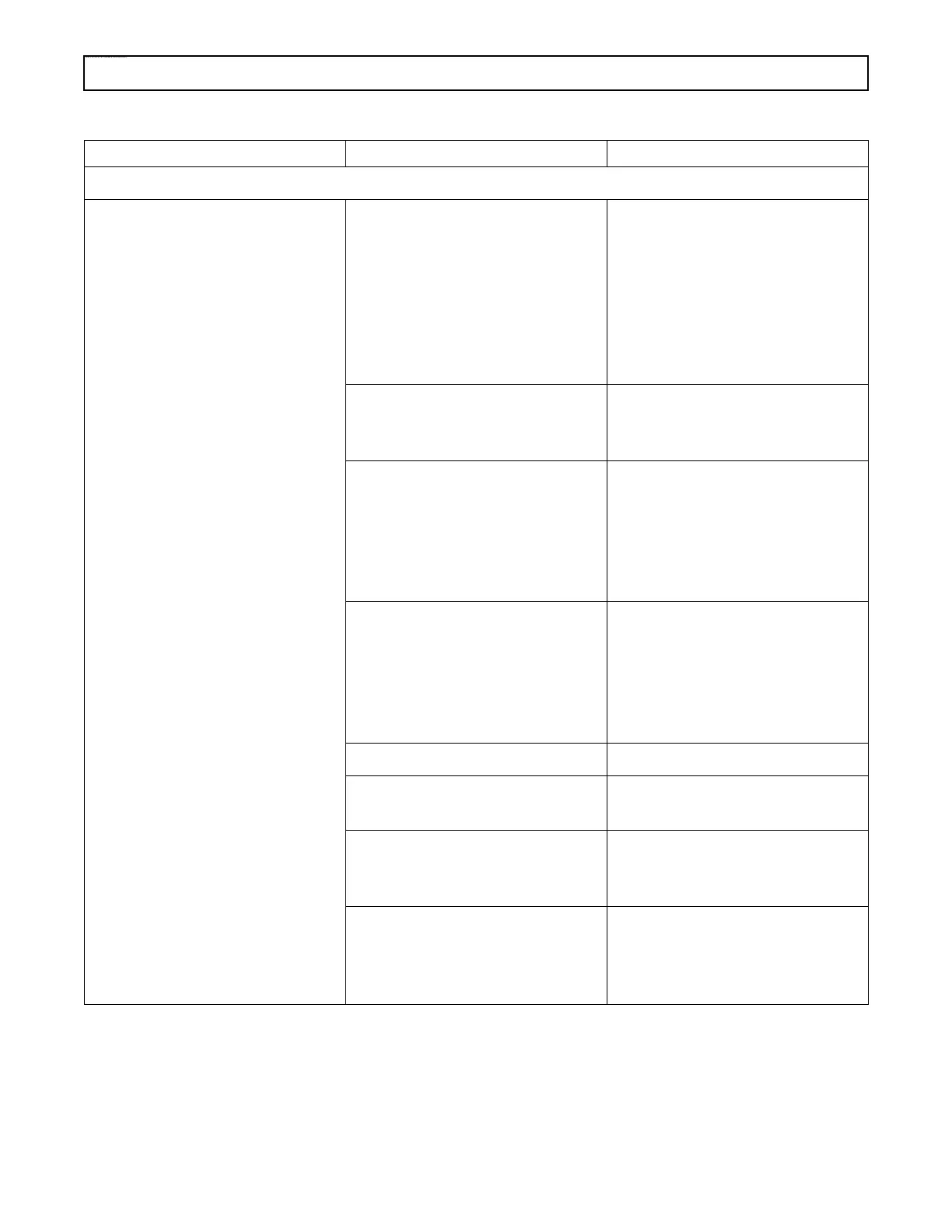

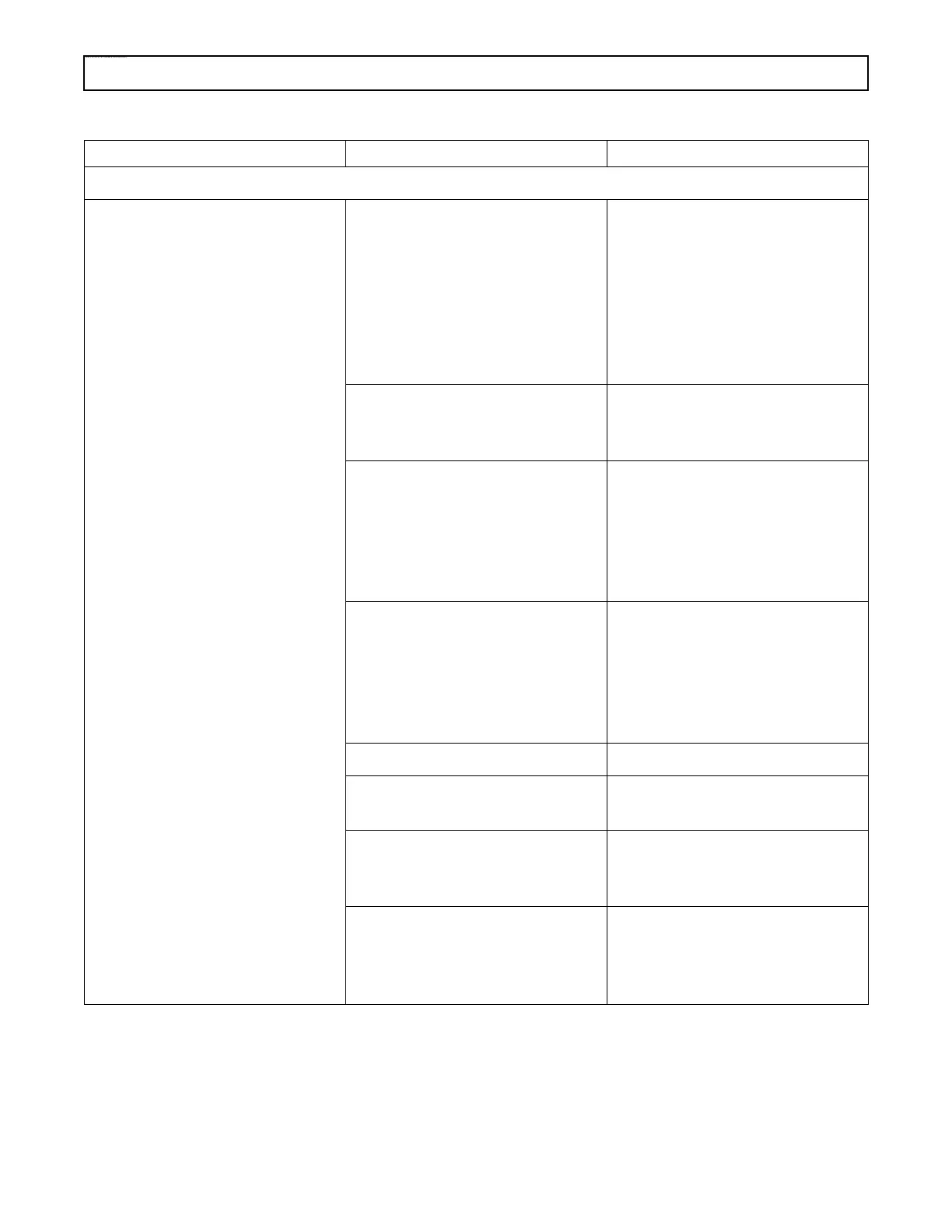

Table 3–13. Troubleshooting Chart

Problem Probable Causes Suggested Remedies

A. Abnormal Automatic Shifts

Shifts occurring at too high speed Governor valve malfunctioning

(stuck).

Clean or replace governor screen

and/or governor. The governor may

be disassembled for cleaning and

inspection only if the kit consisting

of two governor weight pins and

cover gasket is available. Refer to

Paragraphs 5–3e, 5–3h(5), 6–5,

7–10a, and 7–11a.

Vacuum modulator vacuum hose to

engine kinked or leaking — light

throttle shifting delayed.

Replace hose. Be sure vacuum line

is free from kinks or bends and not

close to exhaust components.

Vacuum modulation delayed. Replace vacuum modulator. Be sure

that O-ring is installed and that the

modulator vacuum fitting is facing

forward and positioned 10° below

horizontal. Refer to Paragraphs 5–3c

and 7–11b.

Mechanical actuator cable kinked,

broken, or not properly adjusted.

Replace, adjust, or repair cable. Full

actuator control cable travel must

correspond with full throttle (push or

pull system). Refer to the latest edi-

tion of SA1321, AT Mechanic’s

Tips.

Mechanical actuator malfunctioning. Replace actuator.

Shift signal valve adjustment too

high.

Adjust shift points. Refer to Para-

graph 3–13.

Valves sticking. Replace or rebuild main control

valve assembly. Refer to Paragraph

6–6.

Improper modulation. Inspect and replace, if necessary,

modulator valve and modulator

body. Refer to Paragraphs 6–6a(5)

and 6–6b(16).

Loading...

Loading...