29

Alpha InTec² 26E, 30CE and 35CE - Commissioning

5.9 FINAL ASSEMBLY

1. Raise the control panel and secure in position with the screws provided.

2. Clip the bottom cover plate in position as shown in Fig. 4.4.

3. If the boiler is to be left in service with the User, set the controls, clock (if fitted, see User's Operating manual) and room

thermostat (if fitted) to the User's requirements.

4. If the boiler is not to be handed over immediately, close the boiler gas service cock and switch off the electrical supply.

5. If there is any possibility of the boiler being left during frost conditions, then the boiler and system should be drained

(refer to Section 7.2). It is recommended that a label is attached to the boiler drawing attention to the fact that the

system has been drained.

6. Complete the details of the installation in the Benchmark Checklist at the back of these instructions.

5.10 USER INFORMATION

The User must be advised (and demonstrated if necessary) of the following important points:-

1. How to light and turn off the boiler and how to operate the system controls.

2. The importance of annual servicing of the boiler to ensure safe and efficient operation and maintain the boiler guarantee.

3. That any servicing or replacement of parts must only be carried out by a Gas Safe registered engineer.

4. Ensure that the boiler controls and room thermostat (if fitted) are set to the User's requirements.

5. Tell the User about the sealed system pressure.

6. Tell the User that if the electrical supply is on and the boiler has not operated for 24 hours for heating or hot water, the

pump will automatically operate for 30 seconds.

7. Explain to the User that an internal frost thermostat is fitted in the boiler, and that the electrical supply to the boiler must

be left on for the thermostat to operate, i.e. the boiler must be set to standby.

8. Explain to the User that in certain weather conditions the flue terminal will emit a plume of steam, i.e. water vapour. This

is safe and quite normal.

9. Show the User the position of the condensate discharge pipes.

10. Leave the instructions with the User.

11. Ensure the Benchmark Checklist at the back of these instructions has been completed after the boiler has been

installed and commissioned.

Note: It is a requirement that the installation is registered by the installer through the Gas Safe Gas Work Notification

Scheme.

12. Leave these Installation and Servicing instructions with the User for use on future calls.

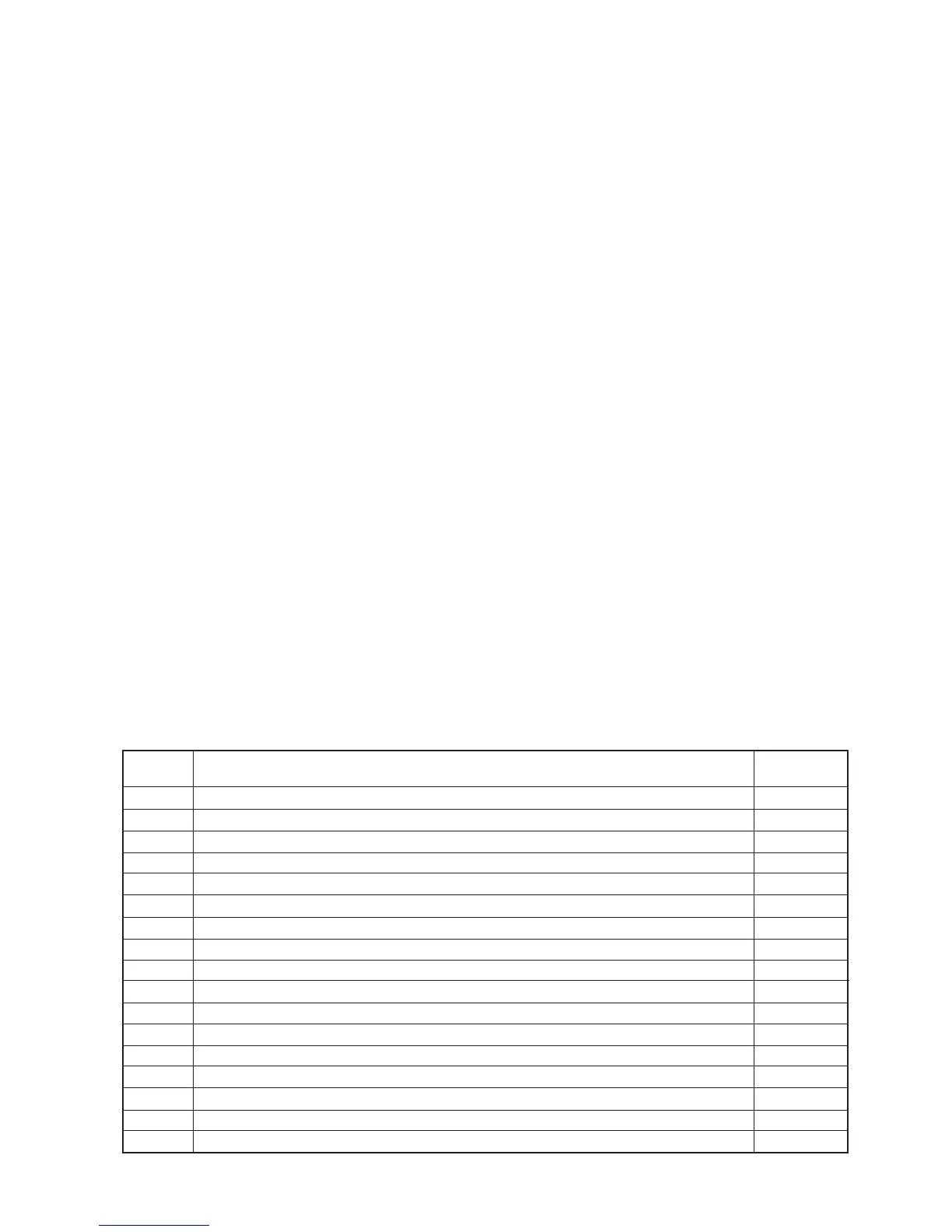

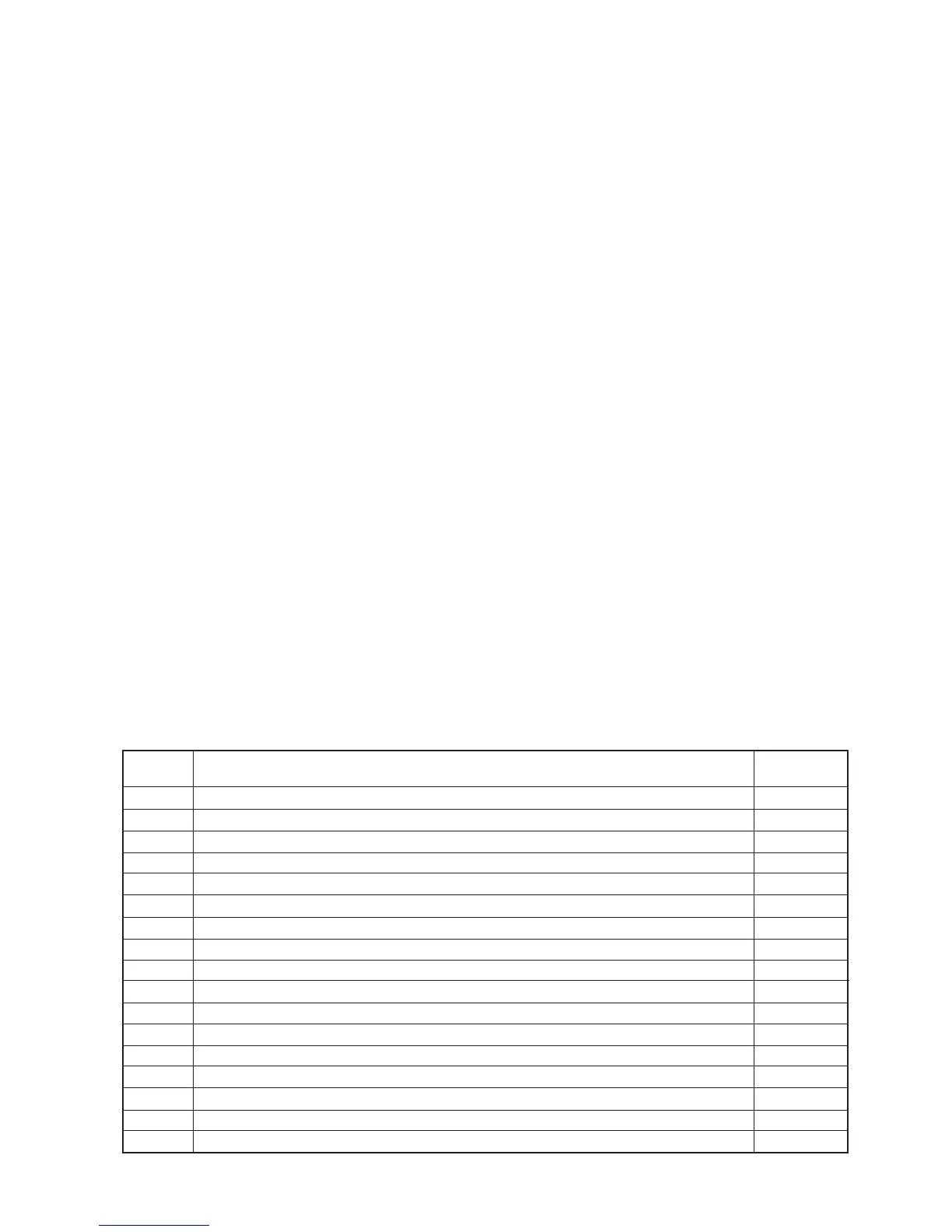

5.11 INFORMATION MENU

By pressing the info button (item 4 in Fig. 5.1) the information menu is accessed, this will then show the information

according to the table below.

Info Menu

(d - prefix)

d0

d1

d2

d3

d4

d5

d6

d7

d8

d9

d10

d11

d12

d13

d14

d15

d16

Information

Optional cylinder temperature adjustment

Flame signal

Central heating flow temerature

Domestic hot water temperature leaving the boiler

Central heating set point temperature

Domestic hot water set point temperature

External weather compensation probe temperature (value flashes if negative)

Mains inlet temperature or FlowSmart cylinder temperature (if sensor fitted)

Central heating return temperature

Fault history - by rotating the CH knob (item 6 in Fig. 5.1) in this menu the last five faults will be displayed

Fault history reset - when in this menu, pressing the reset button will clear the fault code history

Overheat sensor reading

Pump speed (0 = OFF, 1,2,3,4,5,6,7,8,9)

Domestic hot water flow rate

Pump flow rate

Fan speed during current operation

Flue sensor reading

Units

Shown

°C

kOhm/10

°C

°C

°C

°C

°C

°C

°C

Error code

°C

Speed level

l/min

l/h/100

rpm/100

°C

Loading...

Loading...