CHAPTER 3: USING PROGRAMMING FUNCTIONS

IS-300CA INVERTER POWER SUPPLY

3-8 990-418

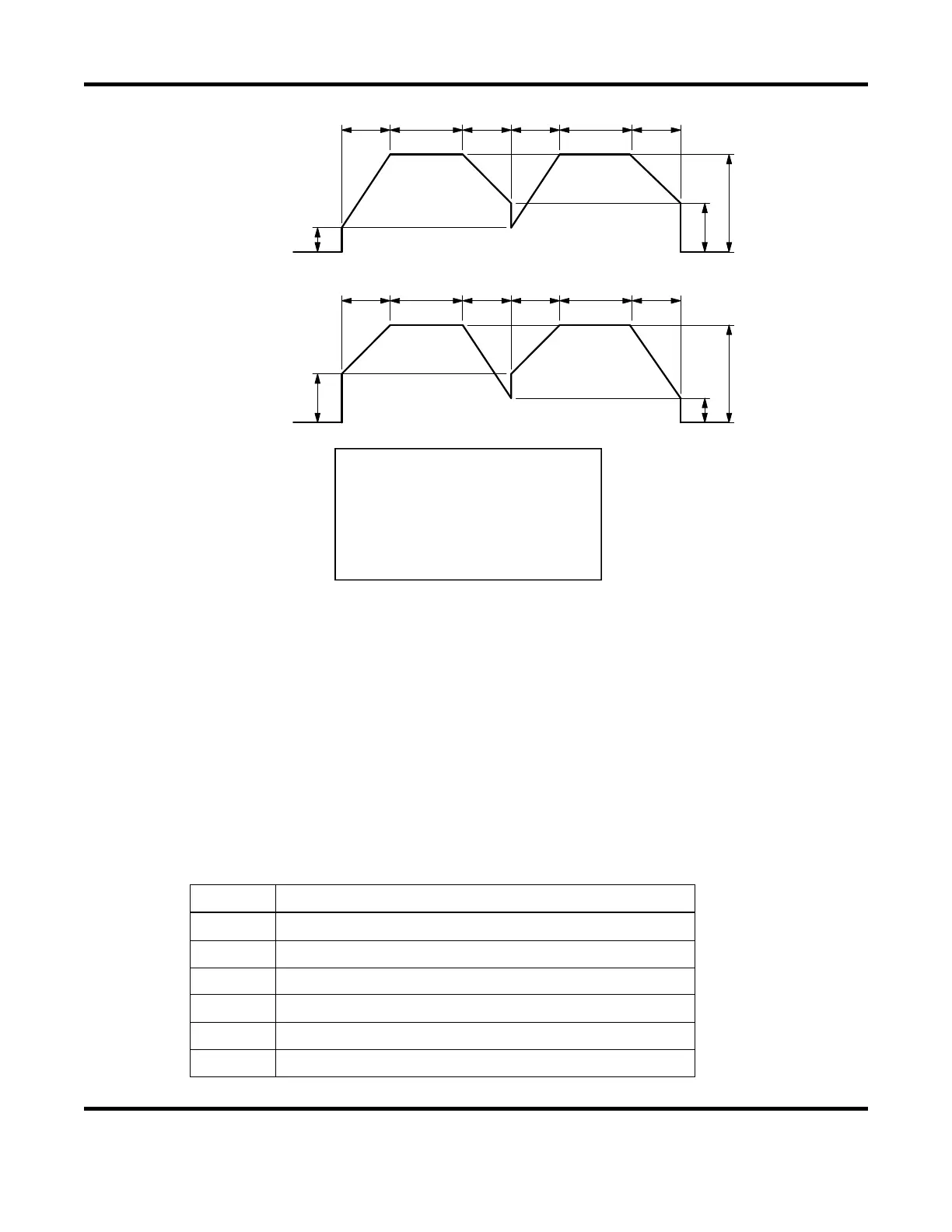

A B BC CA

B BC AA C

DD

E E

FF

d. WELD ON/OFF

One of the settings required to turn the READY lamp of the Power Supply ON.

NOTE: Even if this switch is ON, the Power Supply cannot supply welding current if the WELD

ON/OFF key on the front panel or external WELD ON/OFF signal is OFF. In order for the Power

Supply to supply welding current, this switch, the WELD ON/OFF key, and the external WELD

ON/OFF signal must all be ON.

e. CTRL

Select one from the following six welding current control methods for WE1, WE2 and WE3,

respectively. Press +ON/-OFF key to switch the setting. The initial setting is the secondary

constant-current effective value control (SCD).

Display Control method

PRI

Primary constant-current effective value control

SCD

Secondary constant-current effective value control

PWR

Secondary constant-power effective value control

PLM

Primary constant-current peak value control

VLT

Secondary constant-voltage effective value control

FPL

Constant-phase control

A: UP1 to 3 time

B: WELD1 to 3 time

C: DOWN1 to 3 time

D: UF1 to 3 HEAT

E: HEAT1 to 3

F: DL1 to 3 HEAT

Loading...

Loading...