CHAPTER 3: USING PROGRAMMING FUNCTIONS

IS-300CA INVERTER POWER SUPPLY

990-418 3-9

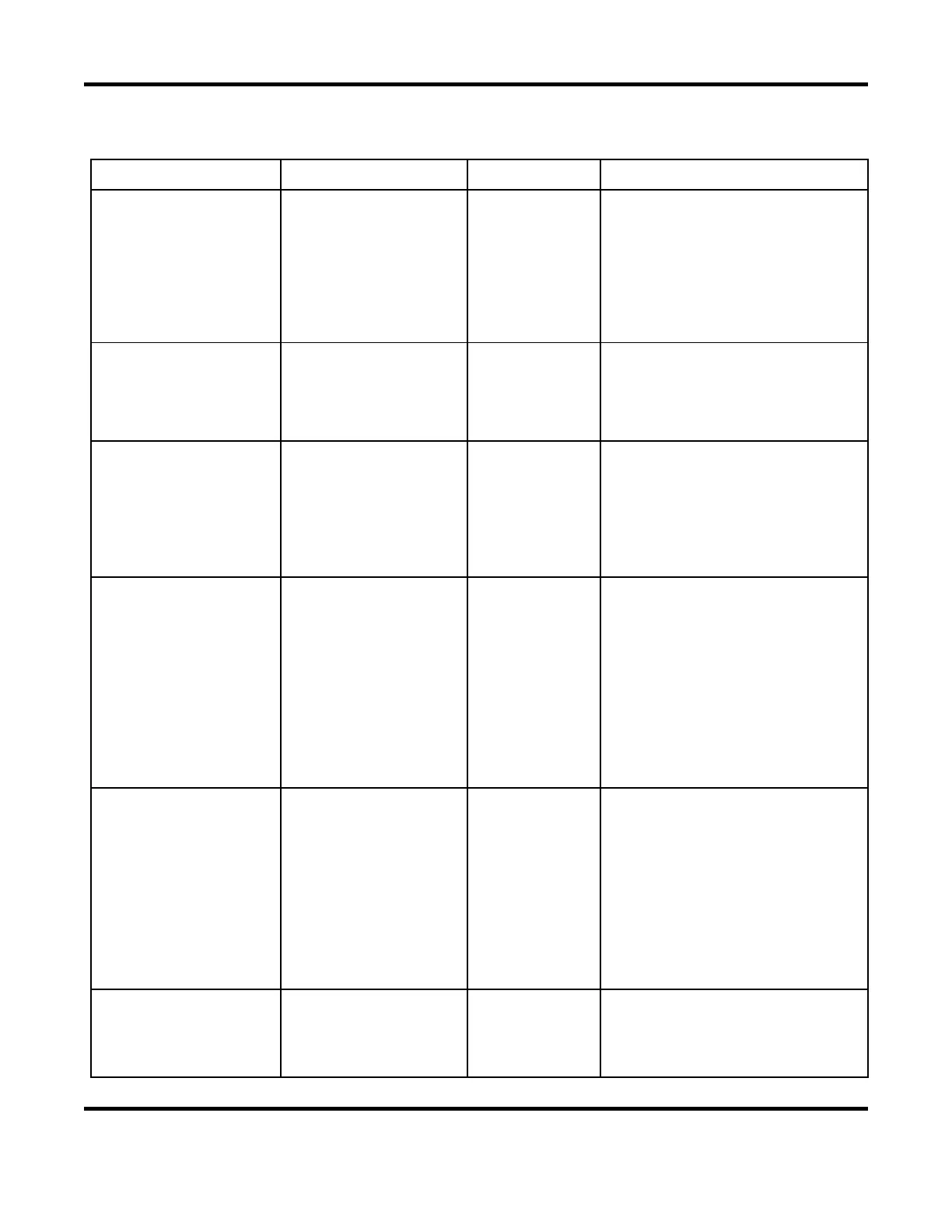

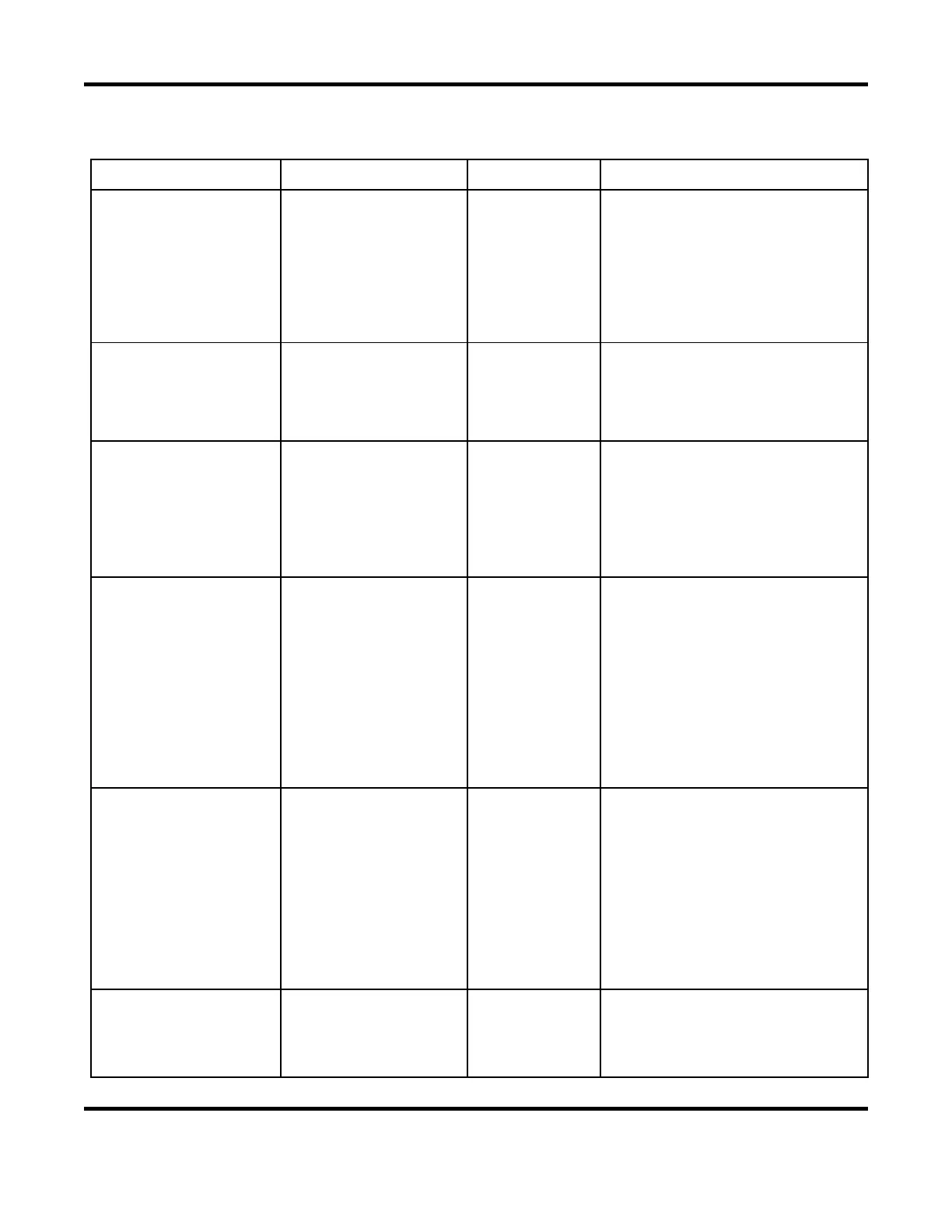

(Note) Control method of the inverter-type welding power supply

CONTROL METHOD FEATURE APPLICATION CONTROL MECHANISM

Primary constant-current

control

(PWM effective value control)

Requires no connection of

toroidal coil on the secondary

side of the transformer.

Requires turn ratio setting of

the inverter-type transformer.

The loss inside the

transformer is not considered.

Used for welding in

a robot or an

environment where

the weld head

moves and that

causes

disconnection of

toroidal coil and

cable.

Detects the primary current by the current

sensor mounted into the power supply to

compare the measured current obtained by

calculating with each control frequency to

the primary current obtained by “set current

÷ turn ratio”, and controls pulse width so

that there is no difference in these values.

Secondary constant-current

control

(PWM effective value control)

Compared to the primary

constant-current control, the

current accuracy is high since

the welding is directly

controlled, being detecting the

welding current.

Commonly used for

general welding.

Detects the welding current with toroidal

coil to compare the measured current

obtained by calculating with each control

frequency to the set current, and controls

pulse width so that there is no difference in

these values.

Secondary constant-power

control

(PWM effective value control)

Controls so that the power

between electrodes becomes

constant.

Responds to change in work

piece state during welding to

make heat input constant.

Used when you

want to reduce

expulsion in early

welding, shunt

current is occurred

at welding, or make

heat generation

constant.

Detects the welding current with toroidal

coil and the voltage between electrodes with

the voltage detecting cable to compare the

power calculated by the measured current

obtained by calculating with each control

frequency and voltage to the set current, and

controls pulse width so that there is no

difference in these values.

Primary constant-current peak

value control

(PWM peak value control)

Requires no connection of

toroidal coil on the secondary

side of the transformer.

Requires turn ratio setting of

the inverter-type transformer.

The loss inside the

transformer is not considered.

Compared to the effective

value control, the rise of the

current is fast, but the

effective current changes

depending on how large the

current ripple is.

Used for welding of

coated metal or

dissimilar metal.

Sets the primary current obtained by the set

current and the transformer turn ratio as

current limiter, and controls pulse width so

that the switching is turned off when the

primary current detected by the current

sensor mounted into the power supply has

reached to the current limiter.

Secondary constant-voltage

control

(PWM effective value control)

Controls with the voltage

between electrodes.

Provides welding without

expulsion by making voltage

from the rise constant and

reducing the current.

Used for welding of

high specific

resistance material,

welding of high

contact resistance

work piece such as

cross wire, and

projection welding,

which has resistance

change in early

welding to reduce

expulsion.

Detects the voltage between electrodes with

the voltage detecting cable to compare the

measured current obtained by calculating

with each control frequency to the set

voltage, and controls pulse width so that

there is no difference in these values.

Constant-phase control

(Non-constant current)

Welding with the fixed pulse

width. No feedback control.

Used for special

cases such as the

test of welder, and

not used for normal

welding.

Controls switching with the set pulse width.

Loading...

Loading...