CHAPTER 3: USING PROGRAMMING FUNCTIONS

IS-300CA INVERTER POWER SUPPLY

990-418 3-11

a. SCHEDULE #

Select from #1 to #255 to set the SCHEDULE. Normally select #1 first, then select additional

schedules in sequential order.

b. PULSE LIMIT

When limiting the pulse width in Primary constant-current peak value control, set the limit for

each of WE1, WE2 and WE3.

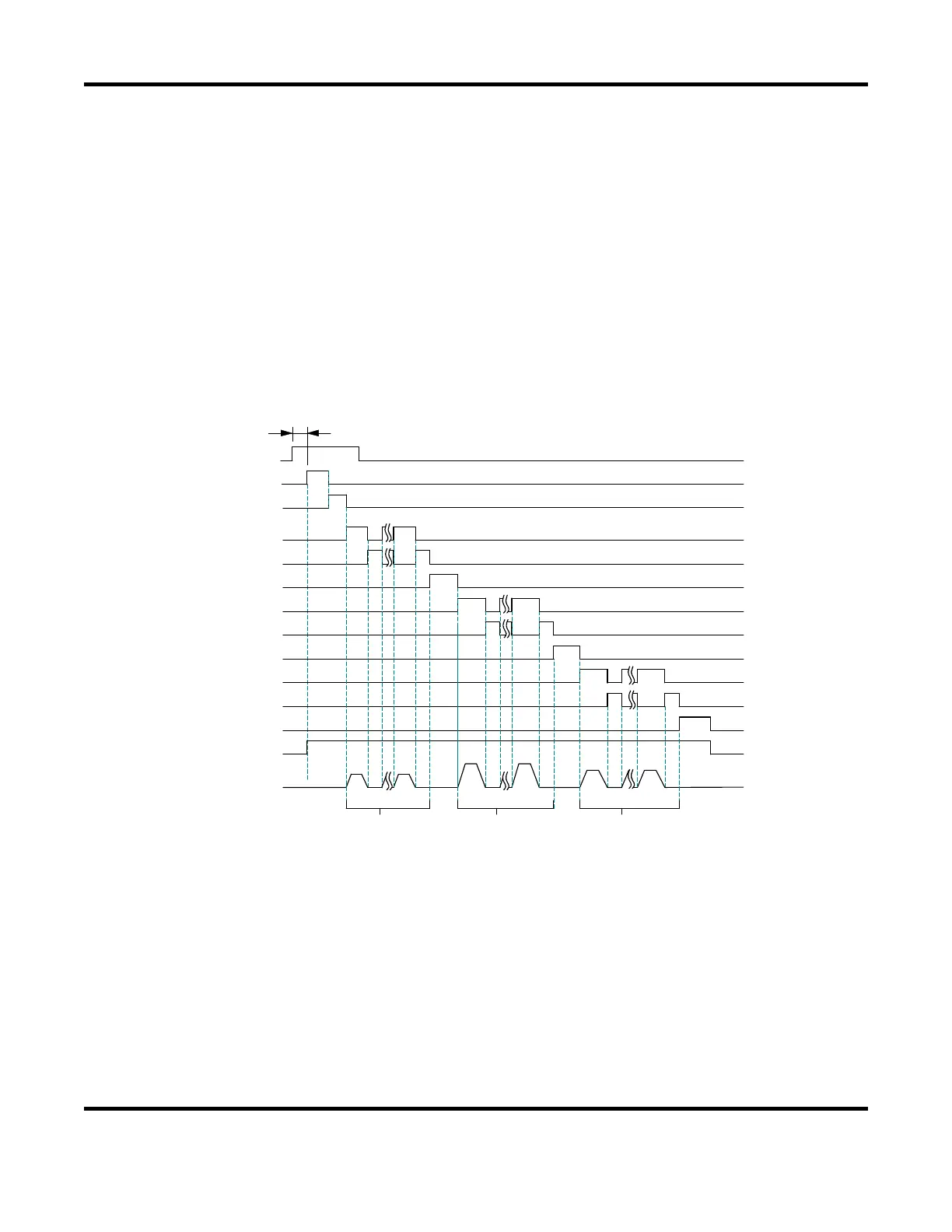

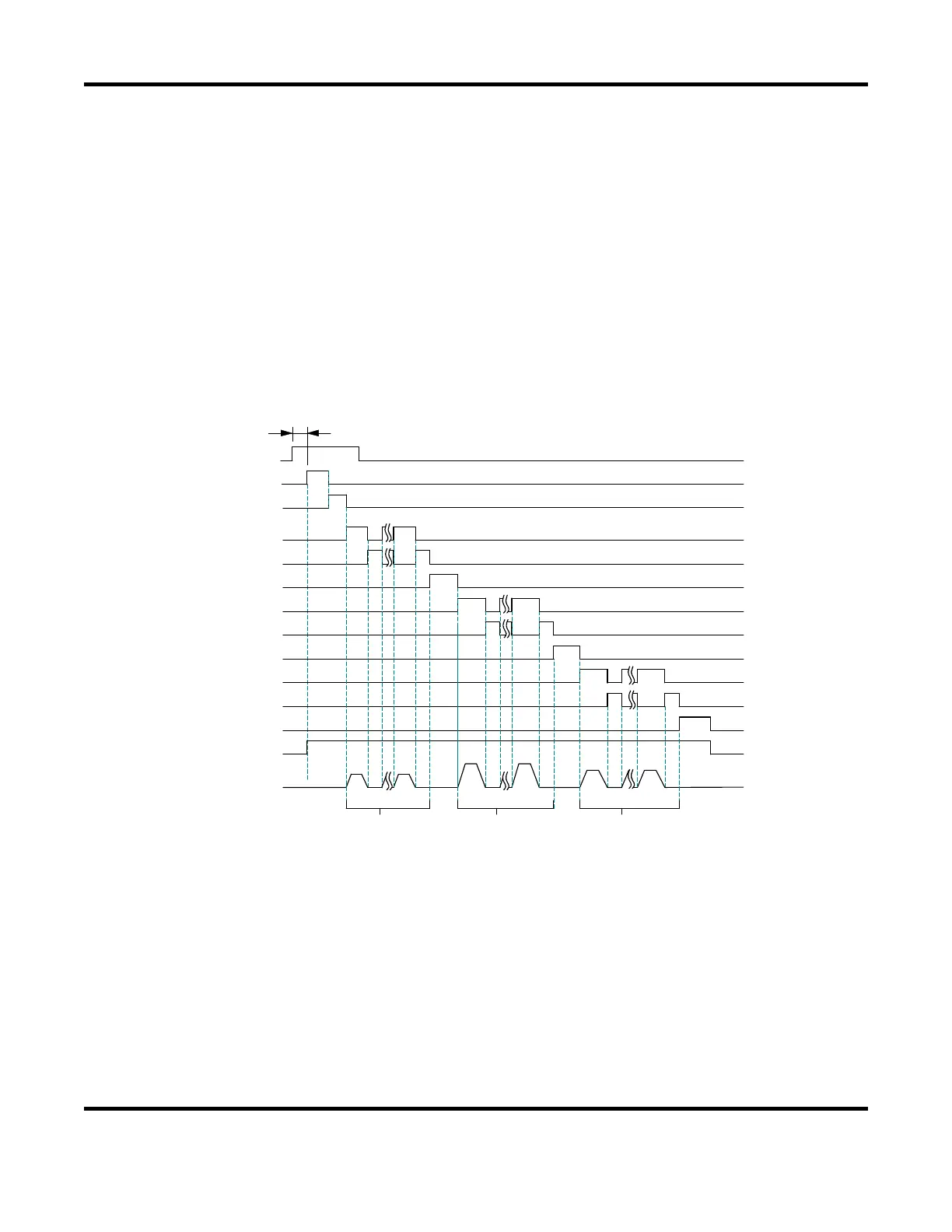

c. PULSATION / INTERVAL 1 to 3

Set the number of repetitions PULSATION (01 to 19) and the downtime (INT1 to 3) in WE1 to 3

(See the figure below); however, when the number of repetitions is set to 01, the downtime does

not work.

2ND

SQD

SQZ

A

A:DELAYSTARTSET

WELD1

COOL1

WELD2

COOL2

WELD3

INT 2

INT 1

HOLD

INT 3

HEAT1 HEAT1

HEAT2 HEAT2 HEAT3HEAT3

PU LSAT ION1

PULSAT ION 2

PU LSAT ION3

VALVE OUTPUT

ELD CURRENT

When performing a welding with the setting PULSATION to 02 or more and INT1 to 3 to 0,

set the control system to the primary constant-current effective value control or the primary

constant-current peak value control. If a welding is performed with the other controls, control

and monitored value may not function correctly.

When performing a welding with the setting PULSATION to 02 or more, only the last welding

data is displayed as the monitored value of

WELD2 after completion of sequence. In the

timing chart above, the data of the third time is displayed, see the MONITOR screen. If the

current gets out of the range of upper/lower limit judgment during repeated

PULSATION

operation, a caution signal is output after completion of welding (see the MONITOR SET

screen.)

Loading...

Loading...