8

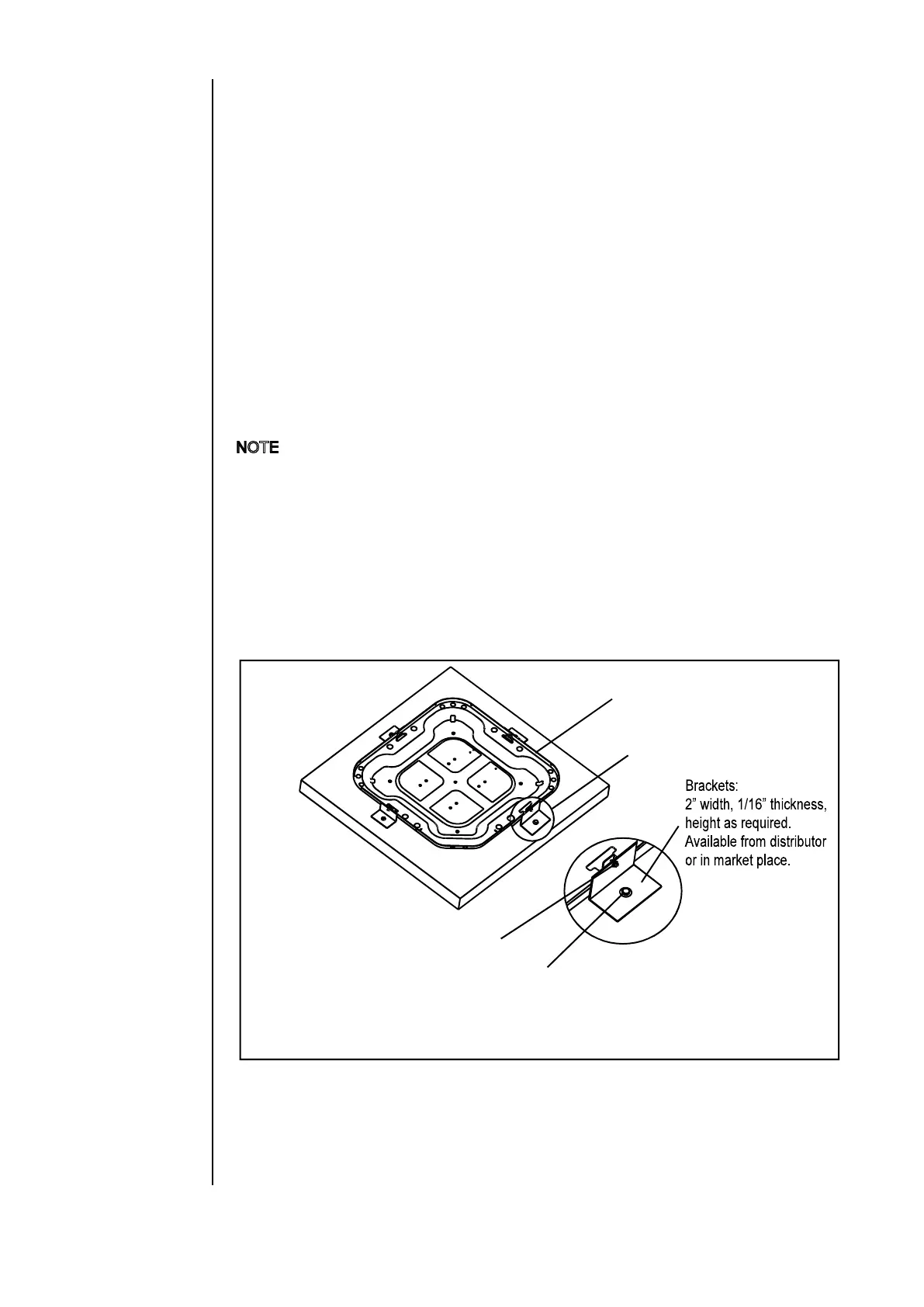

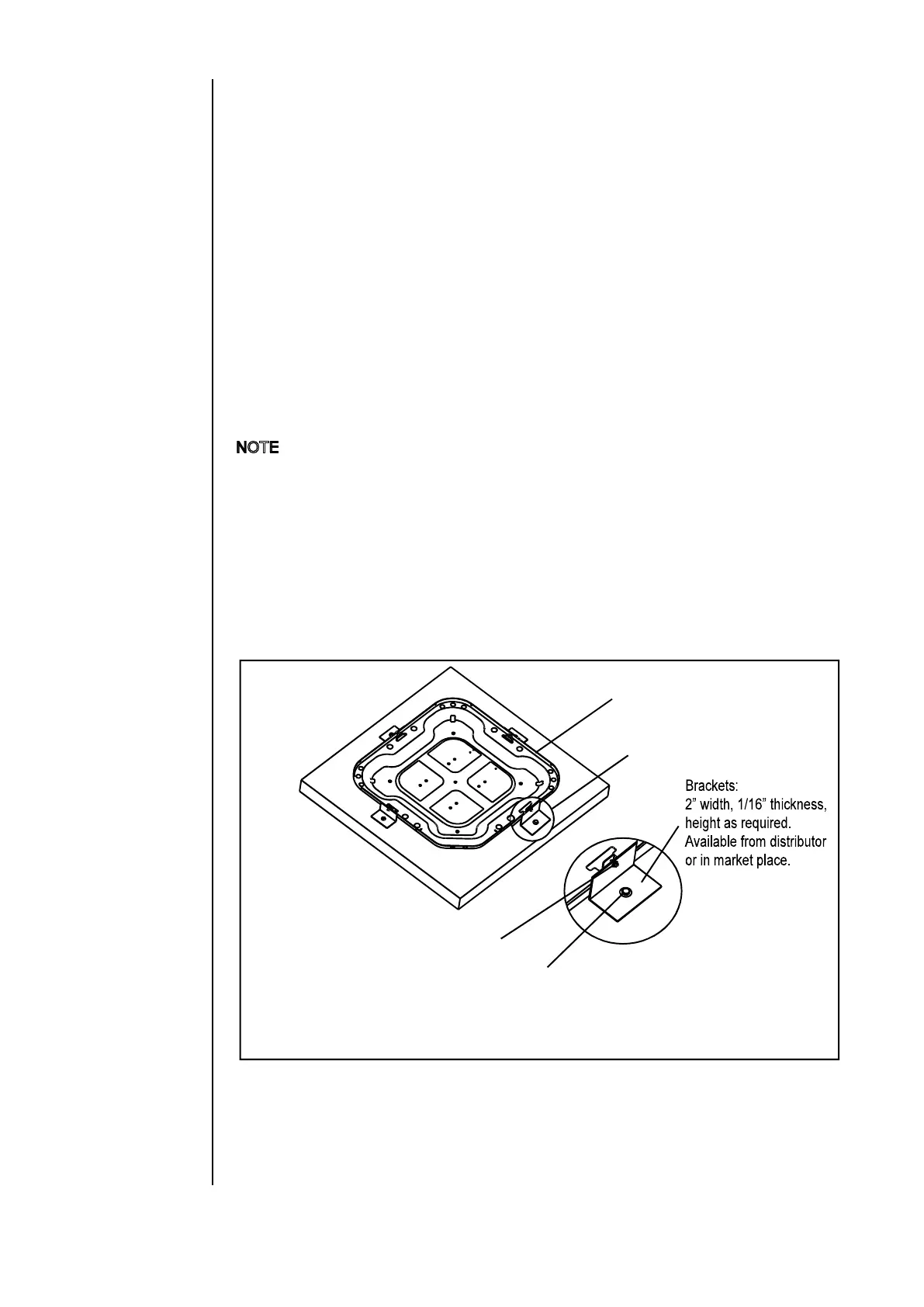

3.6 FACTORY-PREFERRED TIE-DOWN METHOD

Step 3: Using field supplied L-shaped bracket to locate holes on concrete and drill pilot

holes which is at least 1/4” deeper than fastener being used.

IMPORTANT

Self drilling screws to base pan should not exceed 3/8” long to avoid damaging

coil.

Step 4: Using conventional practices to install brackets, tighten concrete fasteners and

self-tapping screws (See Fig.4).

NOTE: 1. One bracket for each side. For extra stability, 2 brackets for each side.

2. Do not over-tighten the concrete fastener to avoid weakening the concrete.

Step 1: Prior to installing clear pad of debris.

IMPORTANT

The pad must meet local codes and must be the proper thickness to

accommodate fasteners.

Step 2: Center and level unit onto pad.

IMPORTANT NOTE:

These instructions are intended to provide a method to tie-down system to cement slab

as a securing procedure for high wind areas. It is recommended to check Local Codes

for tie-down methods and protocols.

REQUIRED PARTS LIST

SEE DETAIL B

#7 X 3/8” Self Tapping Screws

(Don’t Exceed 3/8” long)

1/4” Χ 1-1/2” Hex Washer Head Concrete Screws

(3/16” Pilot Hole Needed. Pilot Hole Should Be1/4” Deeper

Than The Fastener Embedment)

Fig.4 PREFERRED TIE-DOWN METHOD

DETAIL B

The dimension see FIG.2

Loading...

Loading...