2 TrueHVLP™ Spray Finishing Systems

CONGRATULATIONS!! You have just purchased the finest HVLP air turbine system

available. You are about to enjoy the great benefits of TrueHVLP™. Our designs are

the result of many years’ experience in manufacturing HVLP turbine systems, and

HVLP spray guns. We have painstakingly worked and consulted with professional

spray finishers to bring you this versatile, well-engineered tool.

Whether you are new to spray finishing, you have spray finished before, or are just new

to HVLP spraying; there are some basic spray finishing guidelines that will help you to

achieve the best results and optimum success from your new equipment. Reading this

information carefully and following these simple steps

will ensure that you get the best

performance and results from your new TrueHVLP™ spray system.

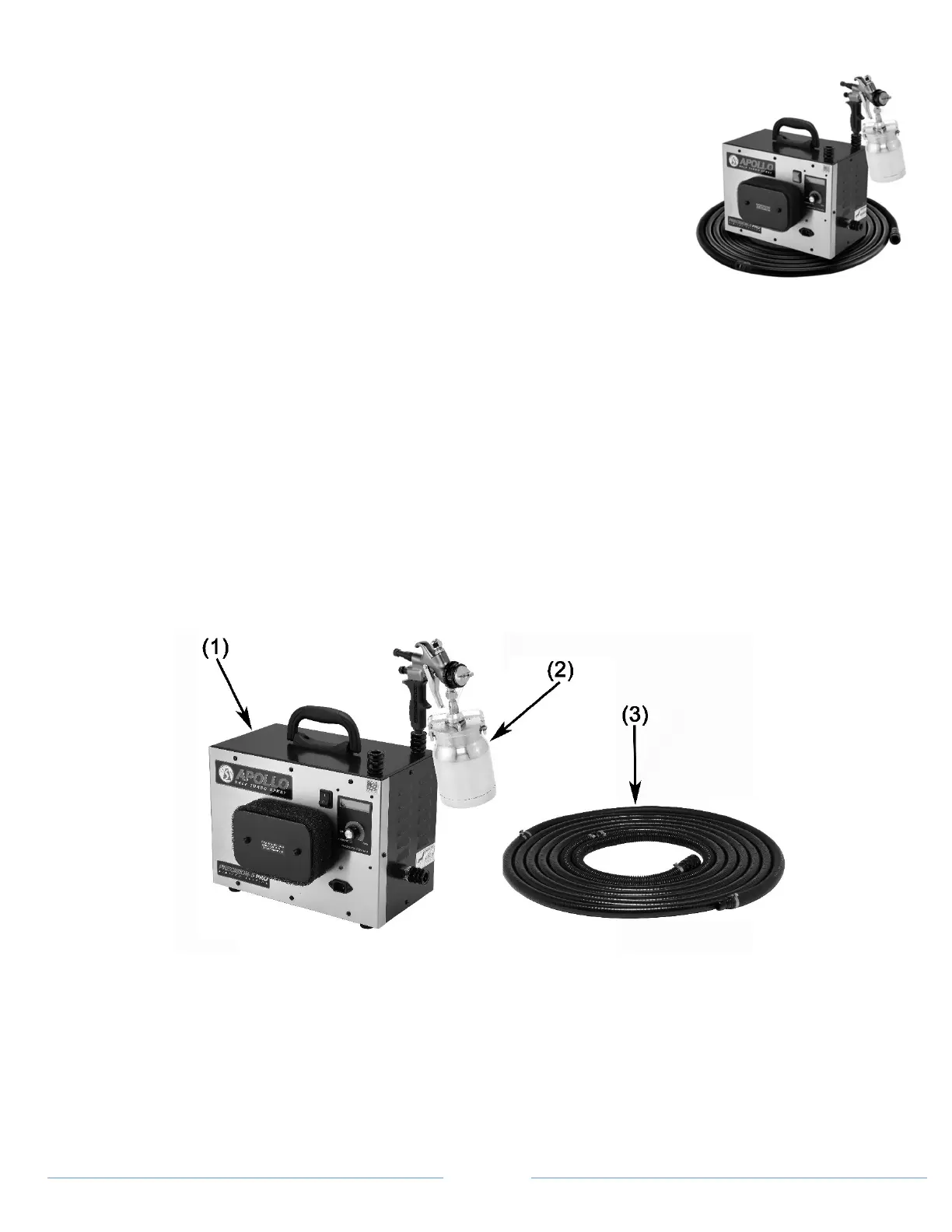

Check the contents of your box. The following are included:

(1) Precision-5 PRO LE Turbine Unit

(1) TrueHVLP™ Spray Gun

(1) 32’ Air Hose

(1) Instruction Manual

(1) Wrench

(1) Spray Gun Lube

(1) Cleaning Brush

(1) Electric Cord

(3) Quick Coupler (2x Handi-Hold™)

(1x Hose Coupler)

2.1 How Your HVLP Turbine System Works

Your turbine system has three components: the turbine unit (1), spray gun (2) and air hose (3). The turbine unit, when

connected to the correct electrical power supply and with the on/off switch in the “on” position, provides a continuous

source of

clean, warm, dry, High Volume Low Pressure (HVLP) air. The air hose connects the turbine unit to the spray gun. Air flows

through the hose to the nozzle of the specially designed TrueHVLP™ spray gun. Atomization of the coating is achieved when

the air mixes with the stream of fluid passing through the tip/nozzle. This low pressure atomization principle

achieves minimum

misting (overspray) to the spray environment.

2.2 How Your Spray Gun Works

Apollo offers two types of Turbine Spray Guns. The 5000 series and the 7700 series. The 5000 series spray guns are bleeder

style. When the turbine blower is turned “on”, air will constantly flow through the air cap. The 7700 series spray guns are non-

bleeder style. When the turbine blower is turned “on”, air will only flow through the air cap when the trigger on the spray gun

is activated or pulled back. Air also flows through the air feed tube to pressurize the cup and deliver fluid to the tip/nozzle.

When the paint flow screw is opened and the trigger pulled back, fluid flows through the tip/nozzle mixing with the air flow

delivered from the air cap and projects a fine atomized mist to your work piece. Spray pattern control will vary depending on

the spray gun model. Consult your individual spray gun manual for detailed operation and maintenance of your spray gun.

Loading...

Loading...