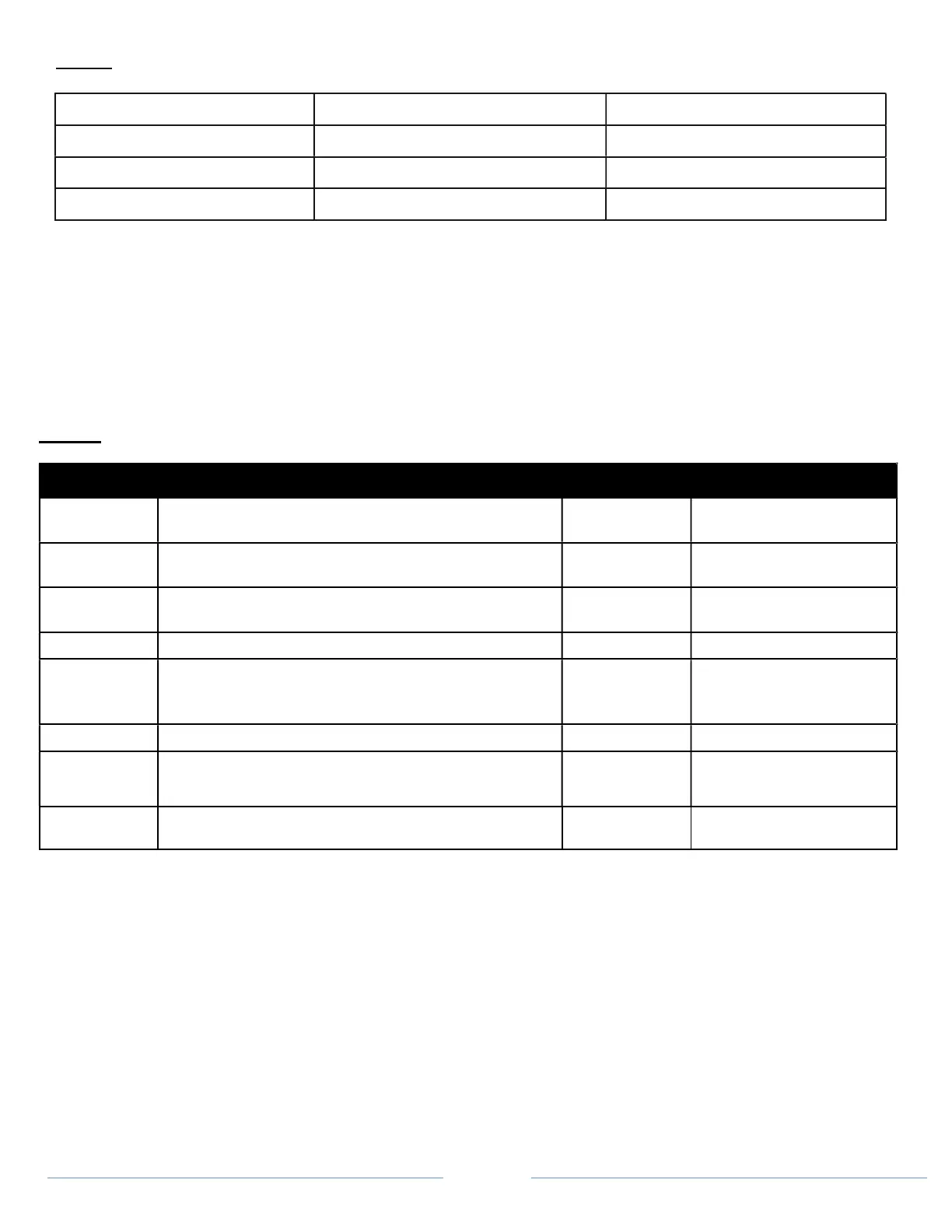

Chart A - Turbine Performance

Turbine Size Sealed Air Pressure Coating Types

3

STAGE

7.0

PSI

Low-Medium Viscosity Materials

4

STAGE

9.0

PSI

Low-High Viscosity Materials

5

STAGE

10.0

PSI

Low-High Viscosity Materials

Using Latex (Emulsion) Paint

Although your turbine spray system is best suited to spray Class A Finish coatings such as lacquers, enamels, urethanes,

varnishes, waterborne and water base etc., you can spray latex (emulsion) house paint if you follow a few simple rules.

First

, it

is generally necessary to thin latex (emulsion) paint. This will vary from as little as 10% to as much as 50% depending on the

model turbine you are using and the quality of the paint used. Second, it is necessary to use a larger nozzle and needle set

in the spray gun (1.8mm, 2.0mm or 2.5mm). It is recommended that a latex (emulsion) paint conditioner like Floetrol®, be

added to aid flow-out. These products are sold at local paint stores.

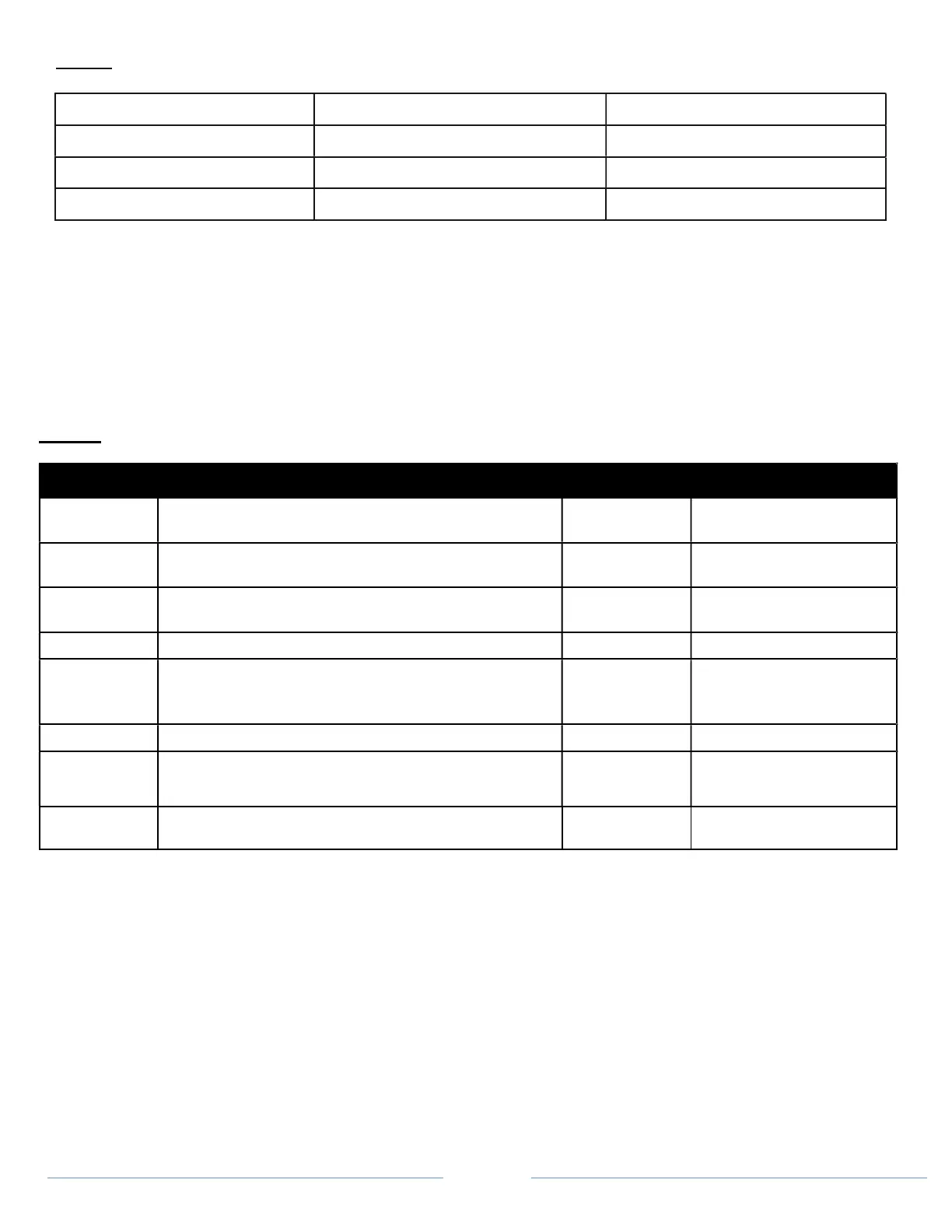

Chart B - Nozzle, Needle and Air Caps For 7700 Series Spray Guns

FLUID NOZZLES, NEEDLE ASSEMBLIES, AIR CAPS & VISCOSITY

TIP/NEEDLE

SIZE

APPLICATION

VISCOSITY

AIR CAP

0.8MM(.031)

Inks, Dyes, Stains, extremely thin viscosity fluids, Water

based finishes

16 seconds A

1.0MM (.039)

All purpose, thin lacquers, thin enamels, Water based

finishes, Automotive, Marine, Airplane finish

16-18 seconds B or B-HS

1.3MM (0.051)

Same as 1.0mm above except slightly higher viscosity

17-20 seconds B or B-HS

1.5MM (.059)

Catalyzed lacquers, Conversion Varnish, Primers,

Automotive, Marine, Airplane finishes, Varnish, High

Viscosity Industrial Coatings, Urethanes, Enamels.

18-24 seconds B or B-HS

1.8MM (0.07)

Same as 1.5mm above except slightly higher viscosity

20-22 seconds C or C-HS

2.0MM (.079)

Thinned latex paint, Multi-spec, Heavy Primers,

Butyrate, nitrate dope, High Viscosity Industrial

Coatings

24-35 seconds C or C-HS

2.5MM (.098)

Thinned latex paint, Multi-spec, Solvent adhesives, Wax

based strippers

35+ seconds D or D-HS

Loading...

Loading...