Applications for Flame Detectors

Flame detectors are used when detection is required to be unaffected by convection cur-

rents, draughts or wind; tolerant of fumes, vapours, steam, dust and mist; responsive to a

fl ame more than 25m away and fast reacting.

Typical applications examples are:

• agriculture – grain and malt processing, animal feed manufacture

• aircraft hangars

• automotive industry – spray booths, parts manufacture

• chipboard and MDF manufacture

• power plants

• printing

• transformer stations

Applications and locations to avoid:

• ambient temperatures above 55°C

• close proximity to cell phone and CB transmitters

• sunlight falling directly onto IR optics

• exposure to severe rain and ice

• fl ickering or moving hot objects

• fl ood or spot lighting falling directly on IR optics

• large amounts of fl ickering refl ections

• large IR sources above 200°C – heaters, burners, fl are stacks

• microwave ovens and dryers

• RF heaters

• obstructions to fi eld of view

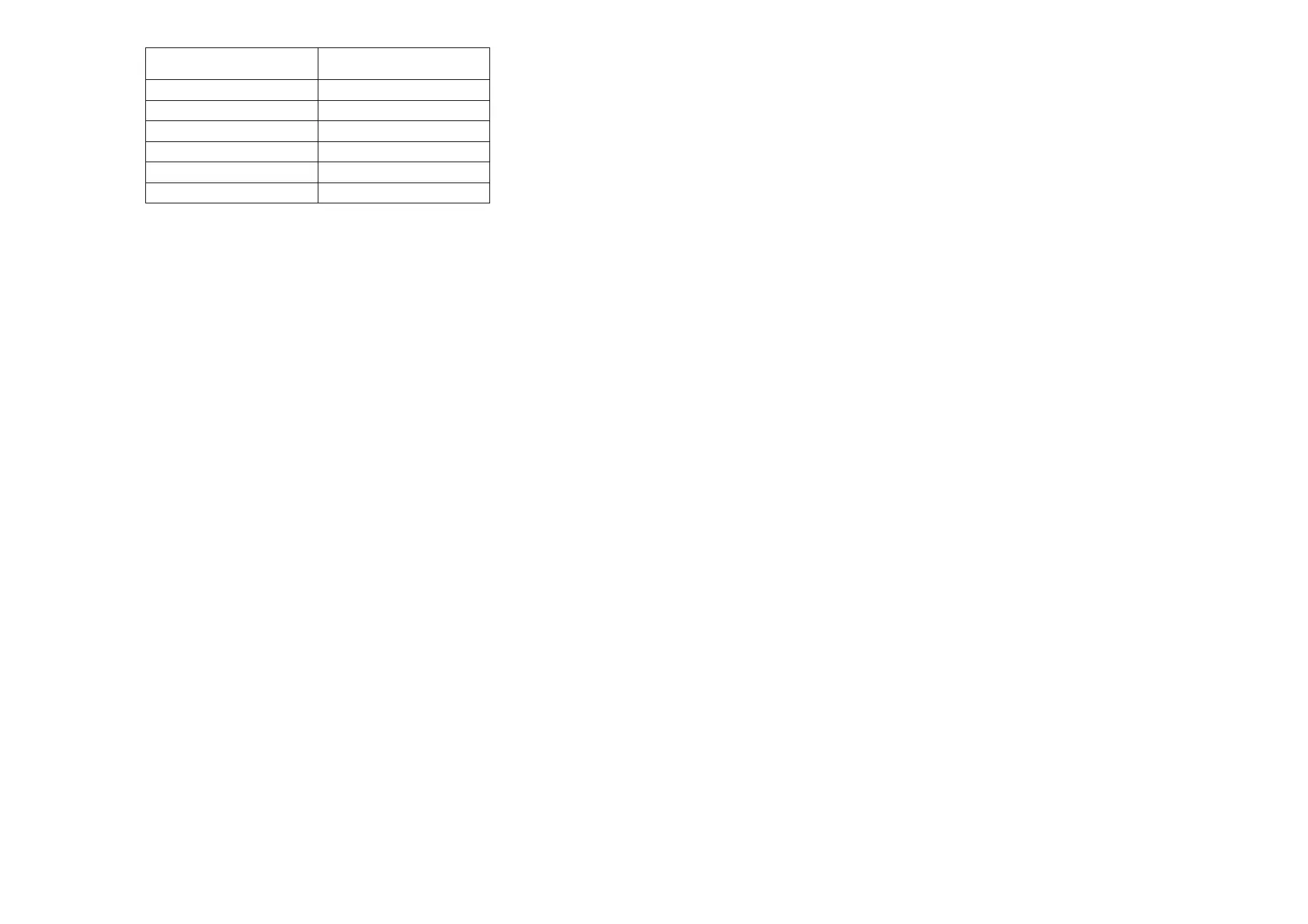

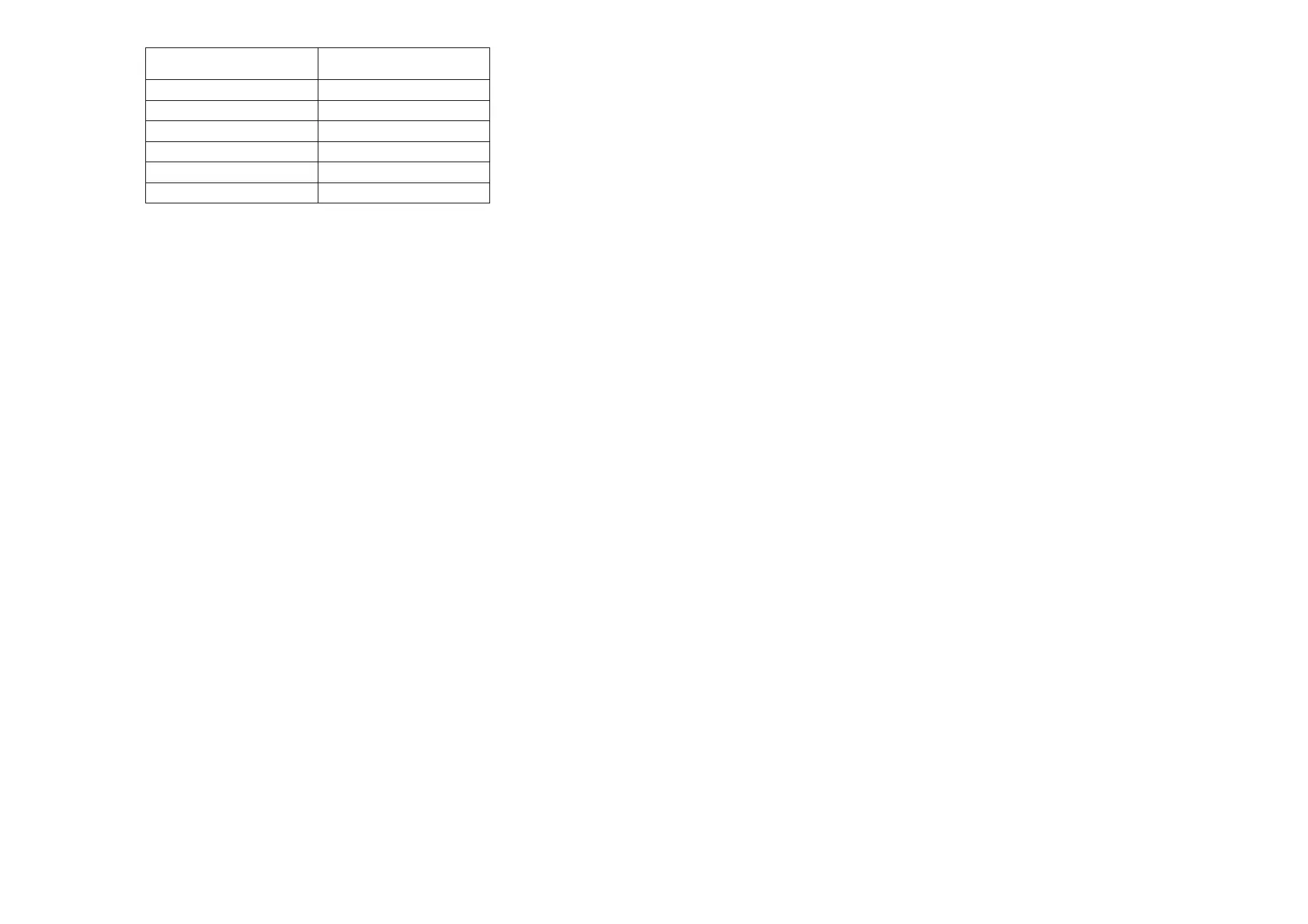

Table 1 Sensor window contamination

Contaminant Typical percentage of

normal response

Water spray 75

Steam 75

Smoke 75

Oil fi lm 86

Salt water fi lm 86

Dry salt deposits 86

Functional Testing

When polled by a compatible panel or test set, the fl ame detector, in quiescent condition,

should return an analogue value of 25 nad input bits set to ‘0’.

If output bit 2 is set to logic 1 on two or more consecutive pollings, the red ‘FIRE’ LED on the

fl ame detector will illuminate.

If output bit 1 is set to 1 on two or more consecutive pollings the fl ame detector will perform

a self test. It does this by causing internal LEDs to fl icker in the fi eld of view of the fl ame

detector, thus simulating the behaviour of fl ames.

If output bit 0 is set to 1 on two or more consecutive pollings the fl ame detector will switch

on a remote LED.

Finally, provided it is safe to do so, carry out a fl ame test using a fl ickering fl ame source,

such as a portable bunsen burner. A still, non-fl ickering fl ame will not produce a response

from the detector.

Maintenance Guide

The fl ame detector is designed to give years of trouble-free operation with minimal atten-

tion. However the periodic maintenance steps listed below are essential to maintain reli-

able fi re protection.

1. Inform all appropriate personnel of intention to work on the fl ame detector.

2. Disable any automatic systems that may be activated by the fl ame detector if not

required as part of the maintenance check.

Alarms Extinguishers Control

Audio/Visual Gas systems Plant stops

Auto diallers Water sprays Dampers/doors

3. Check that the fl ame detector’s control panel is functioning correctly and shows no

faults.

4. Inspect the detector viewing window for any build-up of dust or other contaminants

on the optical surface. If necessary clean the optical surface with a cotton wipe wet with

commercial liquid glass cleaner. Rinse with clean water and dry with a clean cloth.

The detector specifi cation for performance is with a clean optical sensor window. Con-

taminants like dust, oil and paint will reduce sensitivity.

5. Ensure the detector still has a clear line of sight of the area it is protecting and no obsta-

cles obstruct its view.

6. Check that the detector is securely fi tted.

7. Visually check the exterior of the detector for any mechanical or corrosive damage.

8. Test the operation of the detector with either a portable fl ame sensor test unit or if practi-

cal a fl ickering yellow fl ame.

9. Reinstate any automatic system disabled during maintenance.

10. Inform all appropriate personnel on completion of the maintenance work and if neces-

sary record this work.

2 7

Loading...

Loading...