17

Helpful Hints (continued)

AC/R Systems are generally not designed specically for the recovery process, and this is reected in the wide

use of 1/4” access valves with “Schrader”-type valve cores. These valve cores block about 90% of the ow

through the access port, and require the use of core depressors in the hose ttings, which in turn block about

50% of the ow. When le in during the recovery process, both of these items can signicantly restrict the ow

of refrigerant, making the recovery process take up to six times longer to complete.

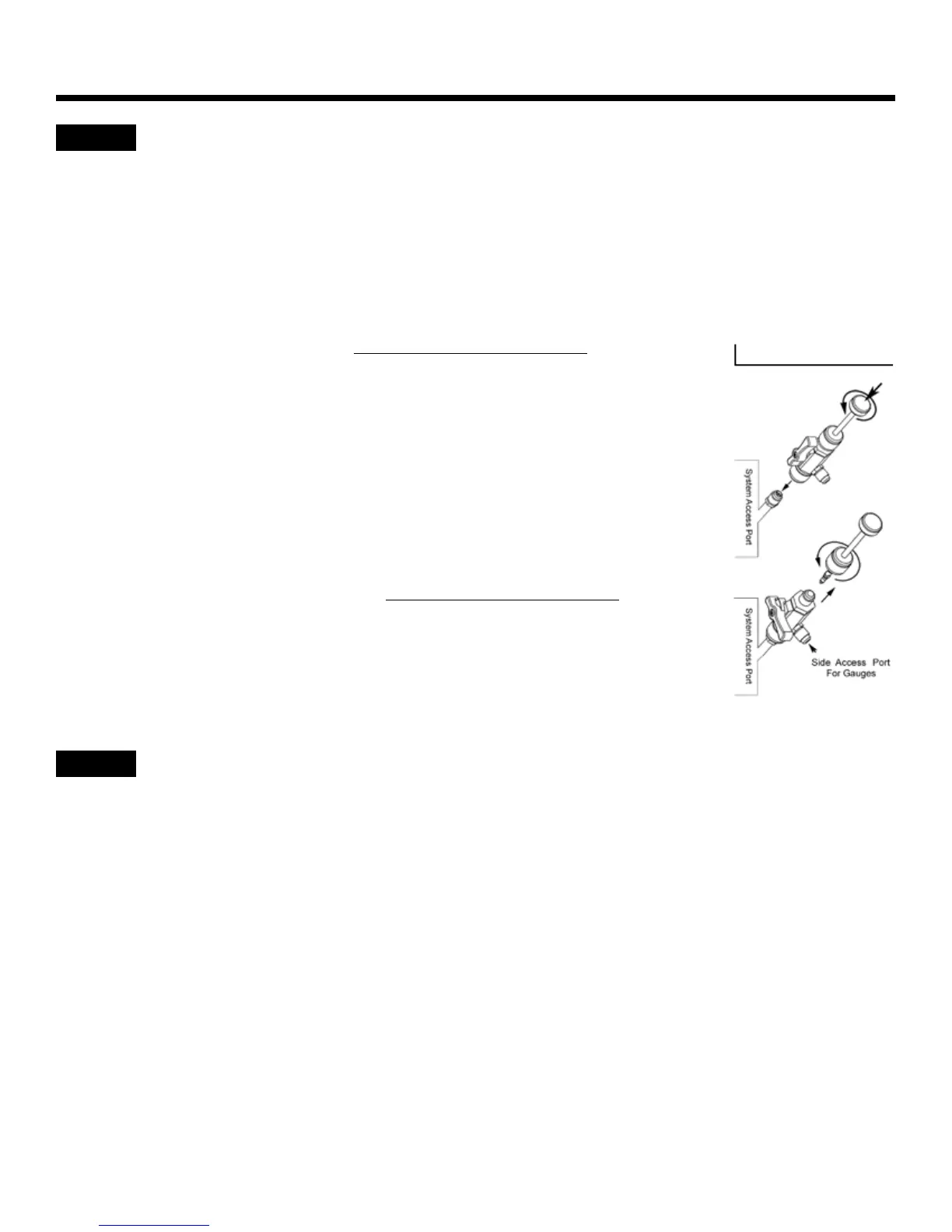

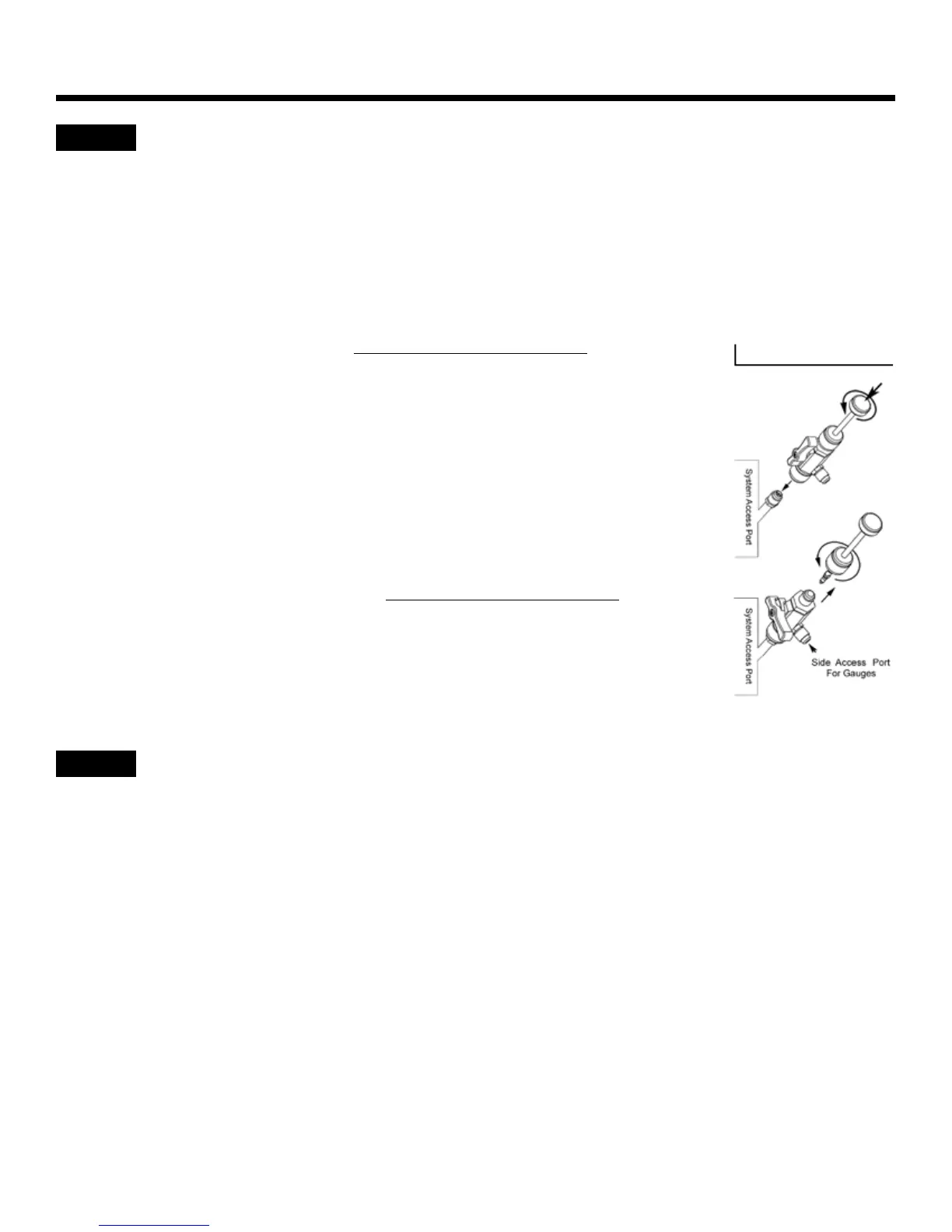

Use a Valve Core Removal Tool to remove these valve cores while leaving the system seal intact, as shown

in Diagram 12. These tools are available from your local wholesale distributor. Core depressors in the ends of

the hoses should be removed as well. See Page 20 for ordering info.

Use ball valves and open-ended hoses. Another common restriction is found in

charging hoses that have “Quick Disconnect, Low Loss” ttings. These ttings use

a restrictive internal check valve to limit venting when disconnecting the hose from

the system. While these may be useful in charging setups, they restrict the ow of

refrigerant, and are not ideal for use in refrigerant recovery.

Use the shortest length of 3/8” hose for fast recovery. The length and diameter

of the hose can also impact the recovery speed. Even when recovering through 1/4”

ttings, the larger diameter hose will allow for greater vapor ow, and greatly reduce

the time needed for the recovery process. See Page 20 for ordering info.

Imagine trying to drink water through a 1/4-in., 3-. long straw. Now pinch the end

closed a little bit, and you get an idea of the kind of work your recovery machine is

trying to accomplish. Using larger hoses without any restrictions will make it easier on

your machine and allow you to nish the job much quicker.

Diagram 12

EXTENSION CORDS AND LOW VOLTAGE

Recovery machines will work best when the voltage at the machine (while it is running) is about 100-105%

of the rated power (115v-122v or 230v-240v). A lower voltage can cause diiculty in starting against high

pressures. If you have low voltage source power, you may need to relieve the back pressure on the unit to

allow it to start.

Check that the voltage coming from the source outlet is adequate. Please note that the circuit could have

many other items on it e.g. light xtures, appliances, or other motors. Also, recovery equipment is used

primarily in the hot summer months when supply voltage can be at the lowest point of the year due to the

demand from A/CR equipment operating at peak conditions. These factors may cause a lower voltage and

reduced performance.

Likewise, long and thin extension cords starve the motor of necessary voltage and can cause very dangerous

overheating of the motor and extension cord. A hot, sunny rooop can also reduce the ampacity of the

extension cord. Refer to the extension cord sizing guidelines on Page 4.

G5TWIN OPERATION MANUAL

© 2016 APPION INC. - ALL RIGHTS RESERVED

Remove Restrictions at the Valves, Fittings & HosesTIP #4

Extension Cords and Low Voltage

TIP #5

Loading...

Loading...