– 31 –

SECTION IX - MAXITROL VALVE ADJUSTMENTS

AND PRELIMINARY CIRCUIT ANALYSIS

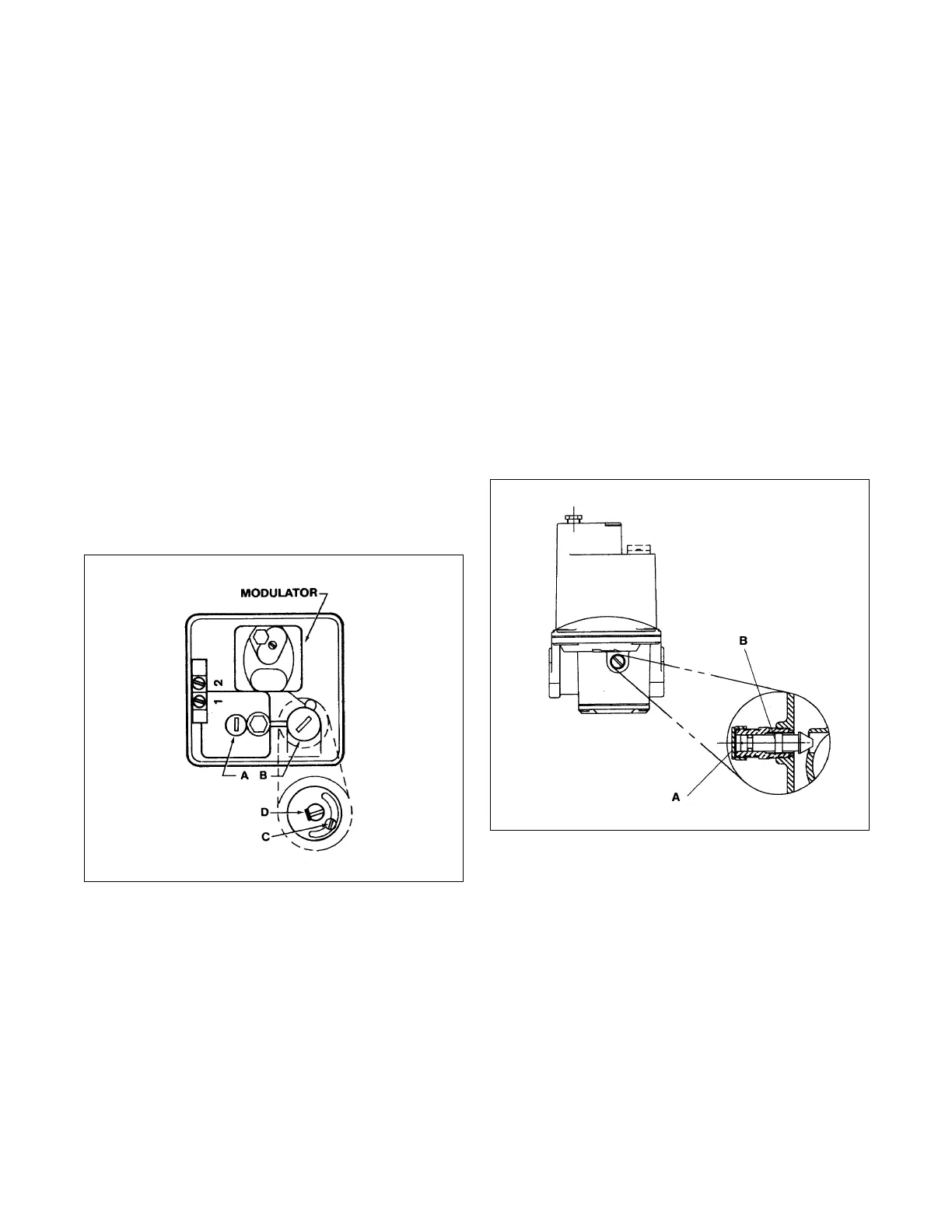

MR212 Valve

High Fire Manifold Adjustments

1. Disconnect wires from amplifier terminal #4 (Series

14), or #2 and #4 (Series 44). This causes the

valve to call for continuous high fire.

2. Remove seal cap (A) and turn regulator pressure

adjusting screw to obtain desired manifold pres-

sure. (Clockwise rotation increases pressure.)

3. Reconnect the wires to amplifier terminal #4

(Series 14), or #2 and #4 (Series 44).

NOTE: If low bypass is on maximum, the desired

high fire outlet pressure may not be achieved.

Low Fire or Bypass Adjustments

1. Disconnect wire from amplifier terminal #8. This

causes valve to call for continuous low fire.

2. Remove cap (B) and loosen lock screw (C). Turn

(D) to desired low fire adjustment. (Clockwise

rotation reduces minimum flow rate.)

3. Tighten screw (C), replace cap (B) and reconnect

wire to amplifier to terminal #8.

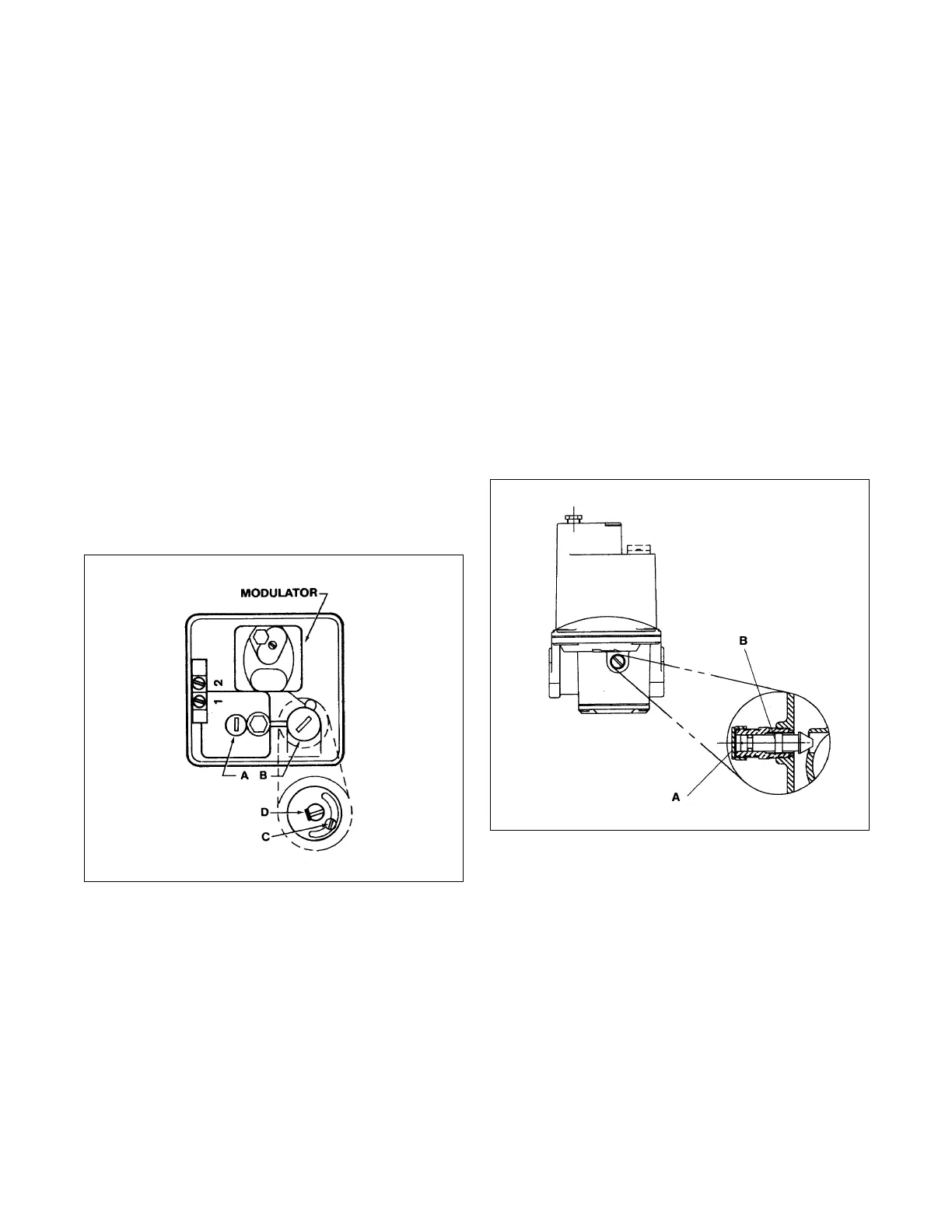

M411, 511, 611 Valve

High Fire Manifold Adjustments

1. Disconnect wires from amplifier terminal #4 (Series

14), or #2 and #4 (Series 44). This causes the

valve to call for continuous high fire.

2. Adjust the pressure regulator to obtain the desired

manifold pressure (7" w.c. maximum).

3. Reconnect the wires to amplifier terminal #4

(Series 14) or #2 and #4 (Series 44).

Low Fire or Bypass Adjustments

1. Disconnect wire from amplifier terminal #8. This

causes the valve to call for continuous low fire.

2. Remove cap (A) and turn adjusting screw (B) to

desired low fire adjustment. (Clockwise rotation

reduces minimum flow rate.)

3. Replace cap (A) and reconnect wire to amplifier

terminal #8.

Loading...

Loading...