– 33 –

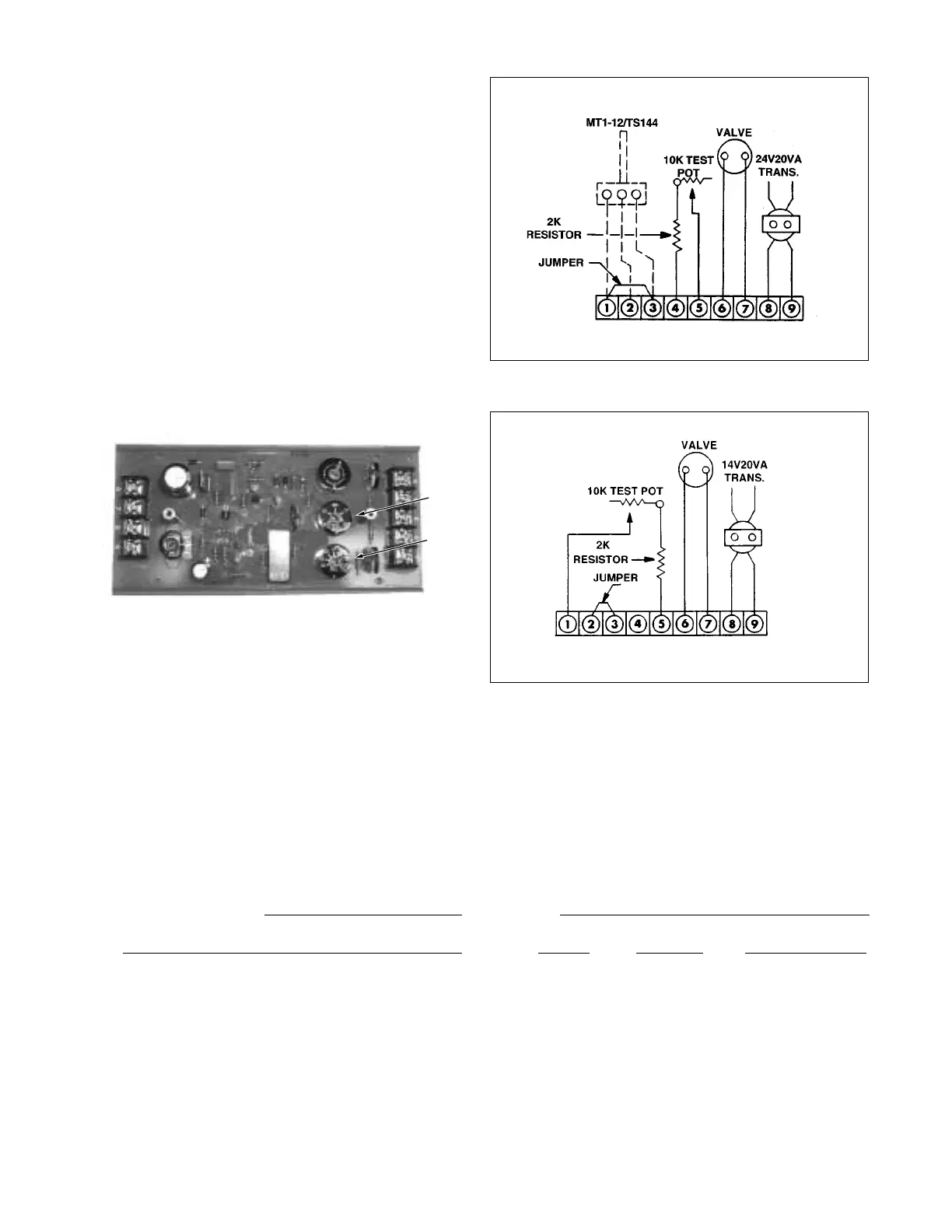

Figure 1

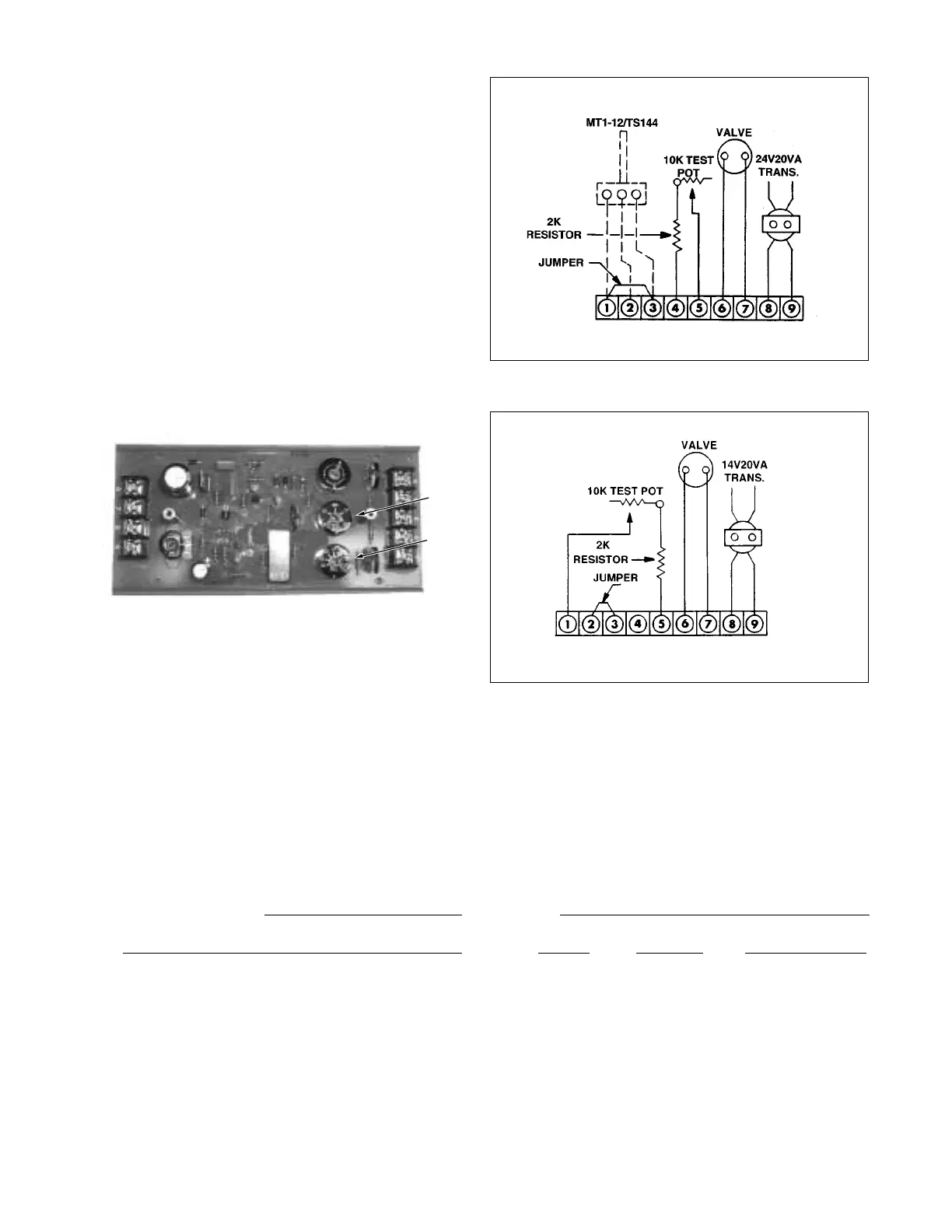

Figure 2

Dealer/Contractor Name:

City:

Address:

State: Zip: Ph:

MAX

MIN

SECTION X-REPLACEMENT PARTS

Replacement parts may be ordered from the factory.

All warranty parts will be shipped freight allowed from

factory for normal ground service. Warranty parts must be

returned prepaid within 30 days. Credit will be issued if

part is complete, defective and returned on time.

When parts are ordered, MODEL NUMBER, SERIAL

NUMBER, FACTORY ORDER (F.O.) and PART

NUMBERS are required. Belts, filters, and fuses are

not covered under warranty.

Section 4

1. With proper voltages observed thus far and modu-

lator responding correctly, wire the system (see

Figure 1), except have TS144 connected in place

of jumper. Set A1044 MIN temperature selector at

least 10°F above outdoor temperature. Set A1044

MAX temperature selector at mid-range. Heater is

now under control by TS144 Discharge Air Monitor.

2. Turn Test-Potentiometer to maximum resistance.

Delivered air temperature should be per A1044

MAX temperature setting. Turn Test-Potentiometer

to minimum resistance. Delivered air temperature

should be per A1044 MIN temperature setting.

If proper delivered air temperatures are observed,

the problem is identified with the space temperature

sensing and/or temperature selecting components

and circuits. See Troubleshooting Guide.

If proper delivered air temperatures are not

observed, check calibration. See Troubleshooting

Guide.

Section 5

1. After test, remove all test equipment and reconnect

all components.

Loading...

Loading...