PAGE 5

5609 RS 01/17

©2017 4Front Engineered Solutions, Inc. - APS Resource

1

1

2

2

3

3

4

4

A A

B B

C C

D D

- CRITICAL QUALITY DIMENSION

TOLERANCES ARE IN INCHES

UNLESS OTHERWISE SPECIFIED

MATERIAL SPECIFICATION

DRAWN

MATERIAL#/PO#

PART DESCRIPTION

DRAWN DATE

JOB/REF NUMBERSCALE

ISSUEPART NUMBER

.X :

0.060

.XX :

0.030

.XXX :

0.010

FRACTIONAL :

1/16

DIAMETER : +0.015 / -0.005

ANGULAR :

1 DEG

AFORM5609-FIG2&6

APS 2000 SUB-ASSEMBLY

NONE

JJS 2/29/2012

UOM

INCH

The information contained herein is proprietary and confidential to 4Front Engineered Solutions, Inc. - APS Resource and is to be

used solely for the express purpose of consideration and development of the article described herein and may not be reproduced or

disseminated without the express written permission of 4Front Engineered Solutions, Inc. - APS Resource.

SHEET SHEET SIZE

C1 OF1

Your After market S olution

APS Resource

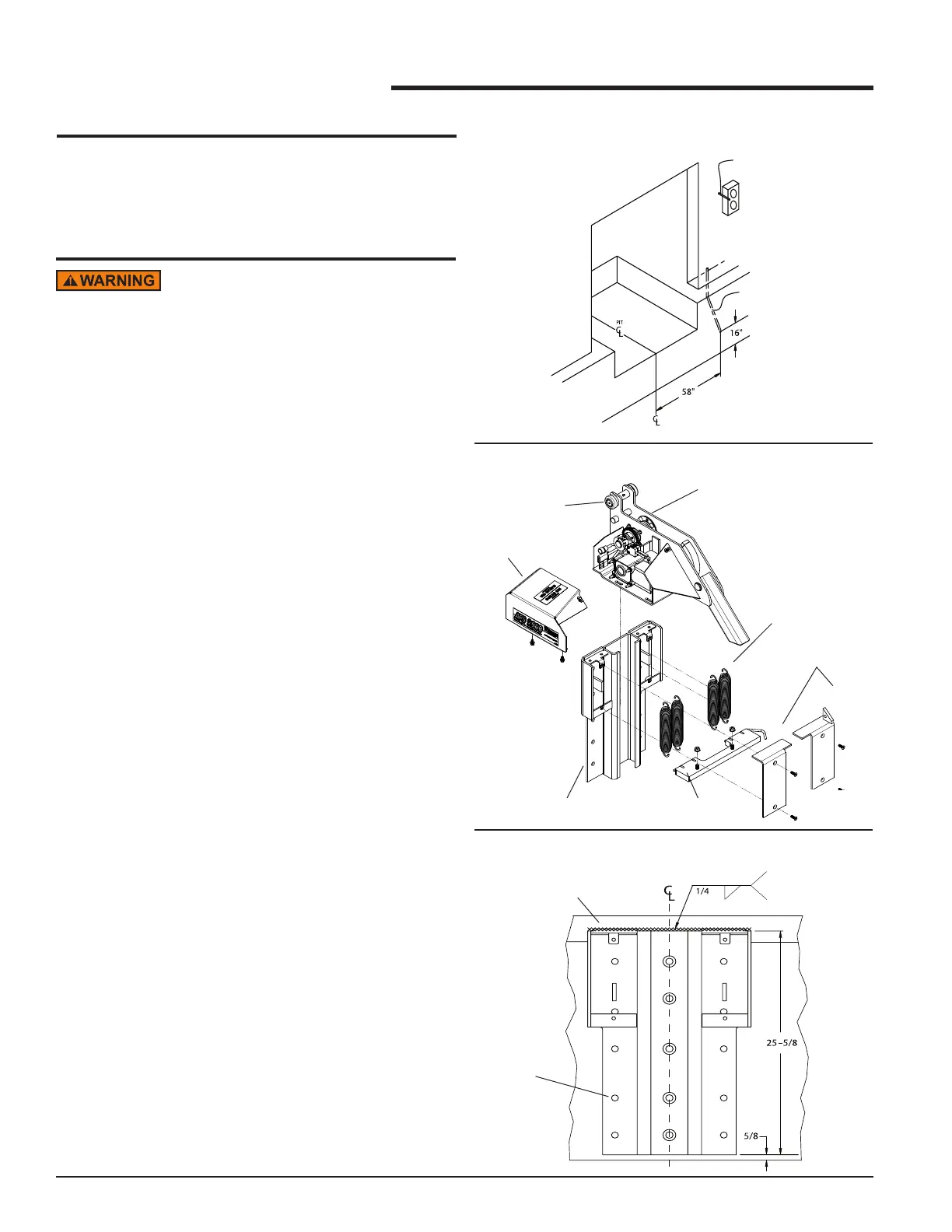

CONDUIT INSTALLATION

1. When installing conduit through building walls and

oors, refer to Figure 1 for reference dimensions.

SEE FIGURES 7 & 9 FOR

LOCATION OF THE CONTROL

BOX AND OUTSIDE SIGNAL

LIGHT.

USE 1/2” DIAMETER

CONDUIT THROUGH

WALL TO OUTSIDE

SIGNAL LIGHT.

EXIT CONDUIT INSIDE

BUILDING NEAR WALL

UNDER CONTROL BOX.

USE 1” DIAMETER

CONDUIT FOR RUN

TO RESTRAINT.

FIGURE 1

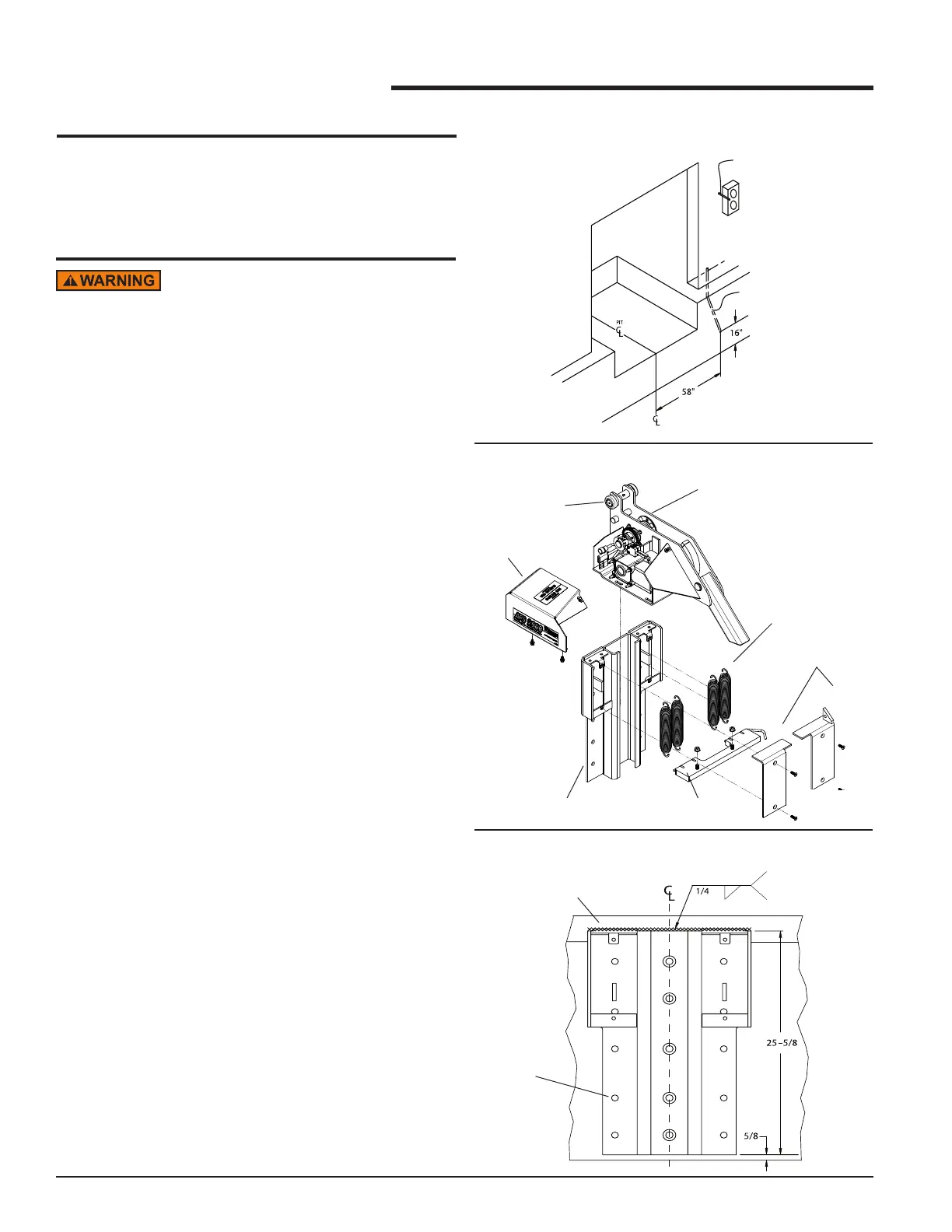

FIGURE 2

FIGURE 3

1. Remove the carriage assembly from the roller track

prior to installation. First, remove the motor cover and

spring covers. Then remove springs and nuts from

spring bar. Slide carriage assembly upwards out of

the roller track, making sure to keep the rollers on the

axles. See Figure 2.

2. Place bottom edge of the roller track plate a

maximum of 5/8" above the driveway and center with

the pit. See Figure 3. If the driveway is susceptible

to heaving from frost, ensure adequate clearance

under the APS 2000

®

to prevent damage from the

driveway movement.

3. Drill 5/8" dia holes into pit wall a minimum of 4-5/8"

deep using holes in roller track as a guide.

FRONT PIT

CURB ANGLE

ALL 15

HOLES

MUST BE

ANCHORED

MOTOR

COVER

ROLLER

CARRIAGE ASSEMBLY

ROLLER TRACK

SPRING BAR

SPRING

SPRING COVERS

CONTINUOUS

WELD ON TOP

EDGE

INSTALLATION

Do not install, operate, or service this product unless

you have read and followed the Safety Practices,

Warnings, and Installation and Operating Instructions

contained in this manual. Failure to do so could

result in death or serious injury. ALWAYS USE

DOCKLEVELER SUPPORT WHEN WORKING UNDER

A DOCK LEVELER RAMP OR LIP.

Place barricades around the pit on the dock oor and

driveway while installing, maintaining or repairing

dockleveler or vehicle restraint.

Improper installation of anchoring devices or

installation into aged or unsound concrete could

result in death or serious injury.

Inadequate lifting equipment or practices can cause a

load to fall unexpectedly. Make sure the lifting chain

or other lifting devices are in good condition and

have a rated capacity of at least 500 lbs for the lifting

angle used. Never allow anyone to stand on or near

the restraint when it is lifted or positioned. Stand

clear of the vehicle restraint when it is positioned.

Failure to follow this warning can allow the restraint

to fall, tip, or swing into people, causing death or

serious injury.

INSTALLATION WITH

PIT TYPE DOCKLEVELERS

Loading...

Loading...