| 3 |

• Certicate of calibration data.

5.0 Unpacking and Inspection

• This product has been thoroughly inspected and tested before shipment and is ready for operation.

• After carefully unpacking the meter, inspect for shipping damage before attempting to install. If any indication of mechanical

damage is found, immediately contact the responsible transportation service and your local ARAD LTD. representative.

6.0 System Description and Measurement Method

• The OCTAVE’s measurement method is based on an ultrasonic, transit-time, dual-beam sensors which determines

the length of time it takes an ultrasonic sound wave to travel the distance between the two sensors located on the

meter’s body. The sensors function as both the sender and the receiver, each one alternating these functions so

that the ultrasonic wave travels both with and against the direction of the ow. Since the ultrasonic wave travels

slower against the ow than with the ow, the time dierence of two waves traveling with and against the ow

leads to determining the velocity of the water.

• The OCTAVE ultrasonic ow meter is a battery-powered precision ow meter designed for linear, bidirectional ow

measurement of water.

• Flow measurement values can be transferred through the standard comminucation - digital or analog output.

• The OCTAVE can be set up for a wide range of applications.

7.0 Notes

• For proper ow measurements, the OCTAVE’s measuring tube should be completely full at all times. Non-wetted

sensors show loss of signal. Though this will not cause damage to the meter, it will, however, not measure ow and

display zero.

• Flow direction: The OCTAVE is a bidirectional ow meter. Note the indicating arrow on the OCTAVE’s display for

forward and backward ows.

• In case of direct sunlight exposure, it is recommended to keep the lid closed, though no direct damage will occur

with the lid open.

• Do not expose the OCTAVE to excessive vibration. To avoid vibration, support the pipeline on both side of the

meter

• Ambient working temperature: -25 to +55°C.

• Water working temperature: 0.1 to +50°C.

• To avoid measuring errors due to air in the ow tube, observe the following precautions:

• Since air collects at the highest point of the system, installation of the owmeter should be at the lowest point.

• Always install control valves downstream of the meter in order to avoid cavitation.

• Never install the meter on a pump suction side in order to avoid cavitation.

8.0 Counter Flanges

• Refer to the standard dimensional drawings for ange spacing, accommodating for the thickness of gaskets.

• Install meter in line with the pipe axis. The ange faces must be parallel to each other.

• Permissible length deviation: Lmax - Lmin 0.5mm (0.02”).

9.0 Start-up

D Check that the meter has been installed correctly.

D Check that the ow rate and volume units are correctly preprogrammed on the display.

D Check that the output module is correctly attached.

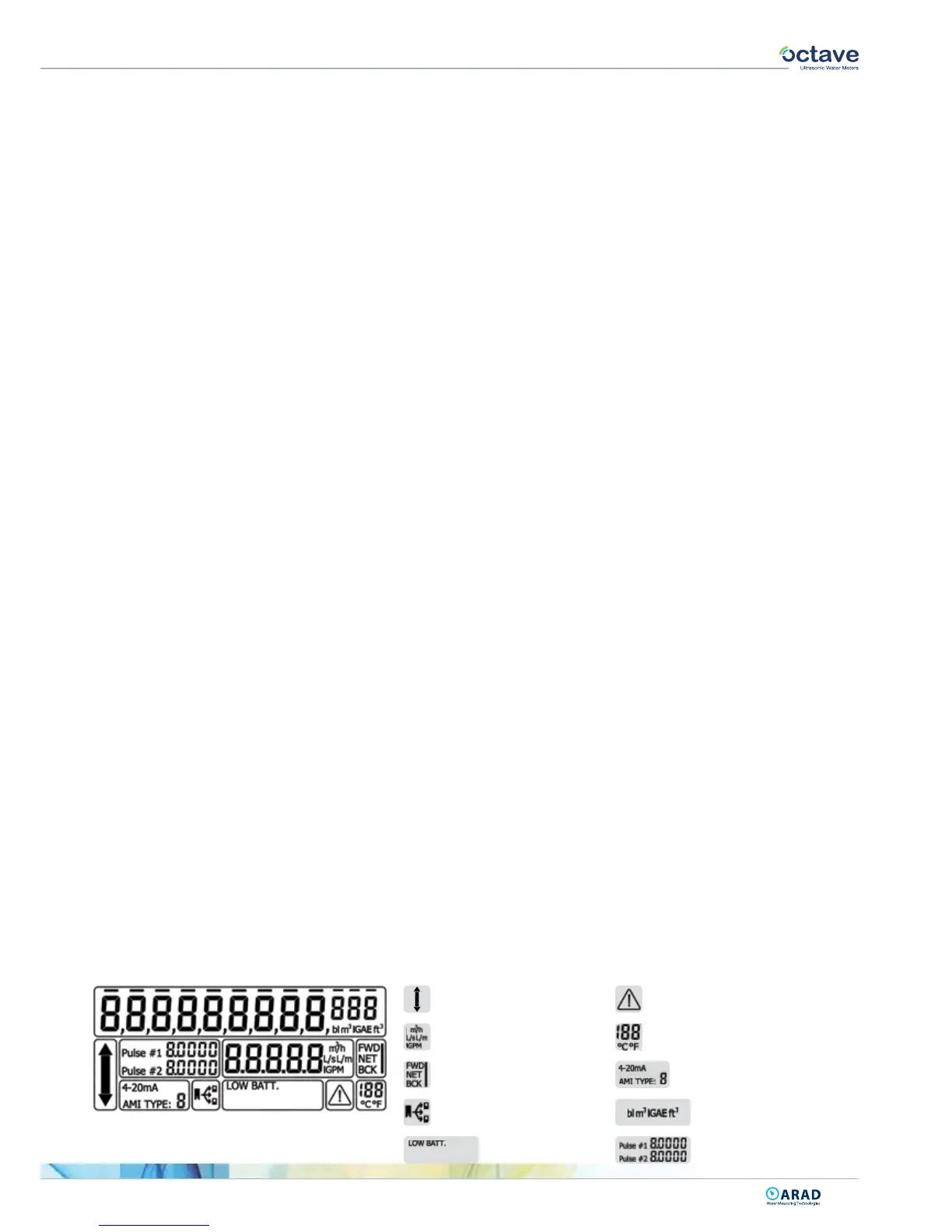

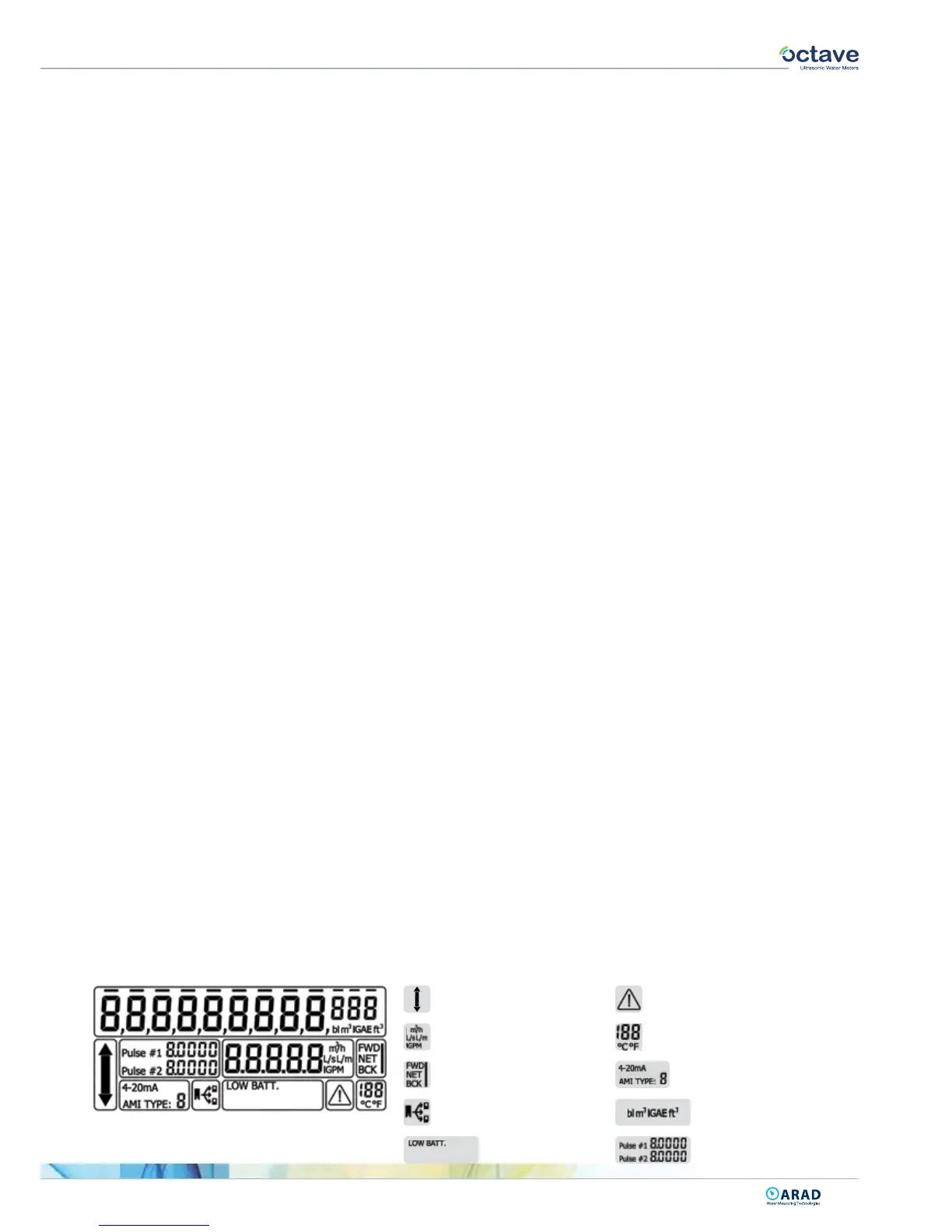

10.0 Digital Display

Flow direction

Volume units

Communication mode

System error

Accumulator mode

Output mode

Pulse resolutionLow battery alert

Flow rate units

Water temperature

Loading...

Loading...