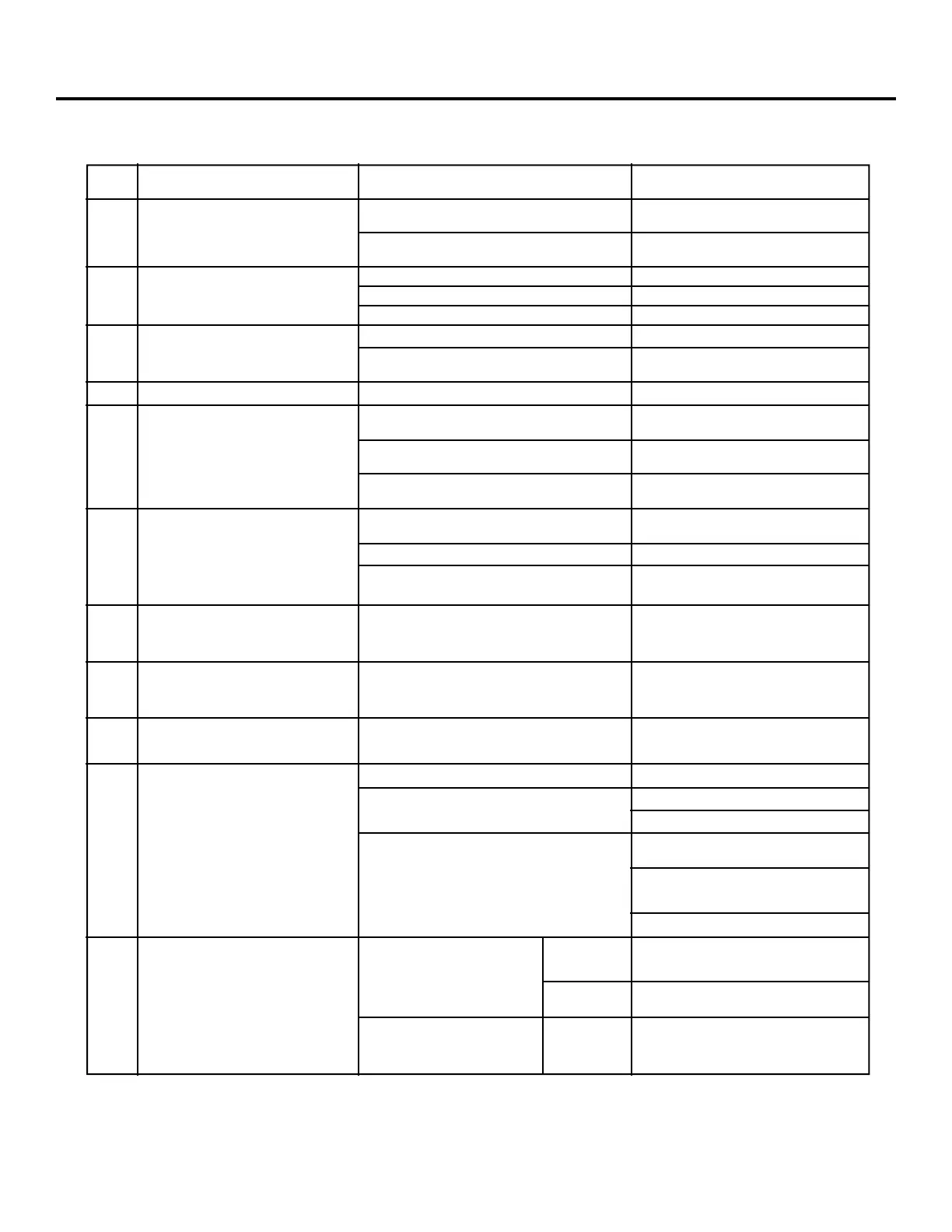

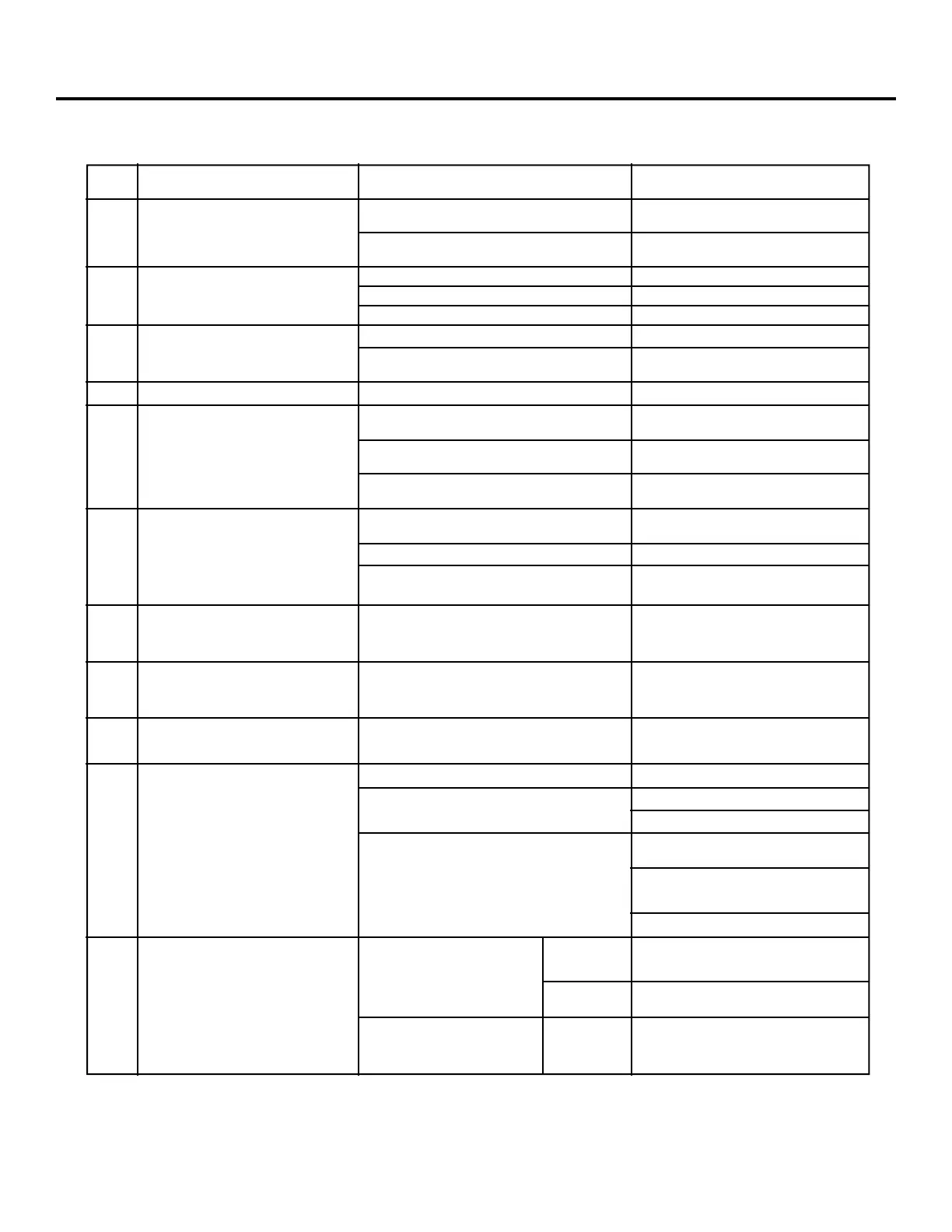

TROUBLESHOOTING

MAINTENANCE AND TROUBLESHOOTING

D-3 D-3

Turn on the power source, and fan

works, but the power light is not on.

Turn on the power source, and the

power light is on, but fan doesn’t

work.

Turn on the power source, and the

power light is not on, and fan doesn’t

work.

The power light damaged or connection is not

good.

Overvoltage (Input voltage is too much or not).

Welding cable is not connected with the two

output of the welder.

The plug loosen or connect not well.

SMAW/GTAW welding selection is wrong.

The welding current potentiometer in the front

panel connection not so good or damaged.

Power PCB failures.

Clear out.

Test and repair the inside circuit of power PCB

Change fan motor.

Check whether there is input voltage.

Check input voltage.

Check the front PCB and power PCB.

Check the earth clamp.

Check and tighten the plug.

Check and clear out.

Select the SMAW weding mode.

Repair or change the potentiometer.

Increase the welding current.

Use the shelter from airow.

Adjust the electrode angle.

Change the electrode.

Use the short arc operation.

Increase the welding current.

The fan motor damaged.

The motor power is faulty.

No no-load voltage output.

Arc blow.

The alarm light is on.

Arc break during welding.

No current output in the welding.

Not easy to start arc in the welding,

or easy to cause sticking.

The welding current can not be

adjusted.

The penetration of molten pool is not

enough(MMA).

No input voltage.

There is trouble inside the machine.

Welding cable is broken.

Earth cable is not connected or loosen.

Oil or dust covered the workpiece.

The welding current adjusted too low.

Airow disturbance.

The electrode eccentricity.

Magnetic effect.

Over current protection.

The welding current adjusted too low.

Over heat

protection.

Over

welding

current.

Working time

too long.

Unusual

current in

the main

circuit.

There is something in the fan

Test and repair the inside circuit of

power light on front PCB.

Repair or change power PCB.

Connect the welding cable to the

welder’s output.

Wrap, repair or change the welding

cable.

Incline the electrode to the opposite way

of the magnetic blow.

Reduce the welding current output.

Reduce the duty cycle (interval work).

Test and repair the main circuit of power

PCB.

Change the position of earth clamp

or add earth cable in the two side of

workpiece.

1

2

3

4

5

6

7

8

9

10

11

Item

PROBLEMS(SYMPTOMS)

RECOMMENDED COURSE OF

ACTION

POSSIBLE CAUSE

Loading...

Loading...