9

Furnace Installation

NOTE: The installation must comply with CAS Standard

B365-M87 - "Installation Code For Solid Fuel Burning

Appliances And Equipment."

If any changes are required on the oil furnace, these must

comply with CSA Standard B139 "Installation Code for Oil

Burning Equipment."

Prepare the plenums and connecting ducts:

• The connecting duct between the oil furnace and the

wood furnace must be 305 mm x 460 mm (12" x 18") with

elbows having a minimum inside radius of 150 mm (6").

• Do not connect duct work so that reverse flow is

possible (the cold air return must not be higher than the

warm air outlets).

• After the installation is complete, recheck the air flow as

before. If the air flow is less than before, the blower speed

must be increased to compensate for the pressure drop

through the system.

• For multi-speed blower motors, use the higher speed, if

needed.

• For belt-driven blowers, adjust the pulley diameter on the

motor to give the extra speed required. If necessary, a

larger blower motor may be used if the faster speed

increases the air flow above the rating on the motor

nameplate. HOWEVER, THE BLOWER MUST NOT BE

CHANGED.

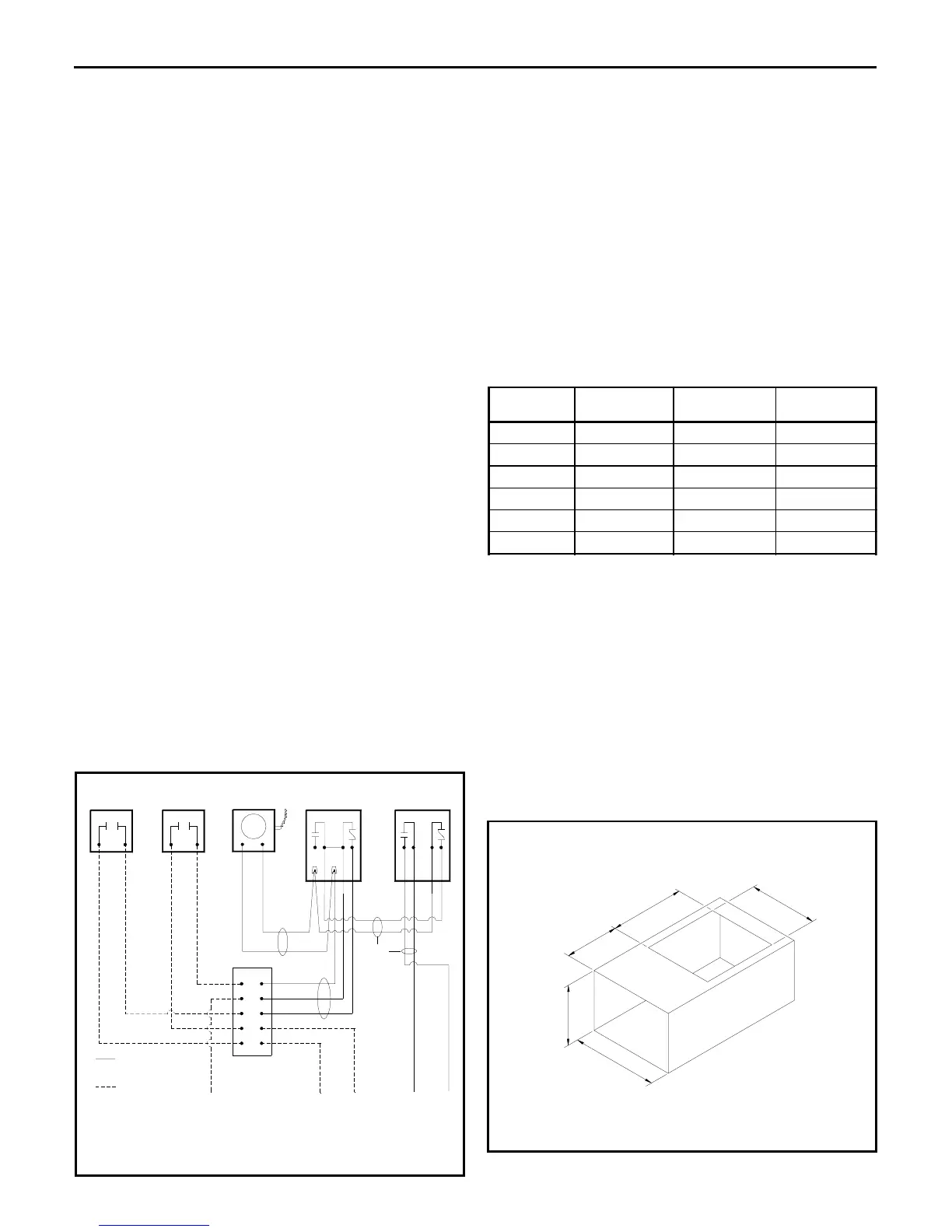

• Follow the wiring diagram precisely.

INSTALLATION AS AN ADD-ON TO AN

ELECTRIC FURNACE

Be sure that you have the following:

• Wood furnace module # F75R or F101

• Control kit model FEFC3, which includes:

• Thermostat

• Damper motor

• 2 fan/limit controls mounted on a bracket

• Wiring harness with LV terminal block

Your electric furnace blower must be large enough to keep

the furnace equal to or below the following maximum tempera-

ture rises:

WARNING: If the airflow is too low, your installation will be

unsafe.

NOTE: The temperature rise must be measured between the

inlet and the outlet of the electric furnace only.

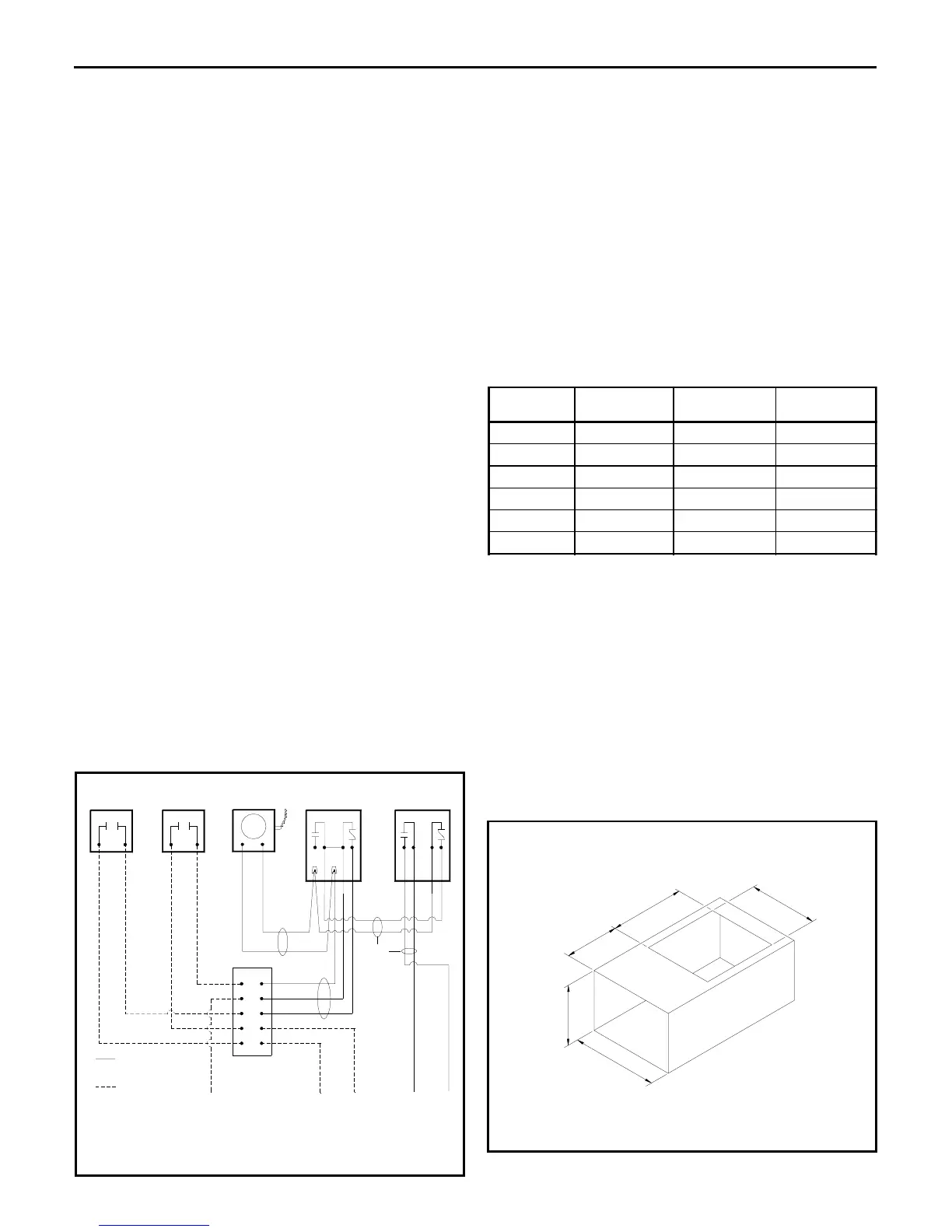

If the electric furnace is certified for counter-flow opera-

tion (upside down) it should be installed according to Figure

5b. Use the connecting duct (part FCADB) in the installation.

Its dimensions are shown in Figure 9.

Furnace Size

Output

(BTU/hr)

Max temp. rise,

F75R °C (°F)

Max temp. rise,

F101 °C (°F)

10 kW 34100 24° (43°) 21° (37°)

15kW 51200 36° (65°) 31° (65°)

20 kW 68200 42° (75°) 41° (73°)

25 kW 85300 42° (75°) 42° (75°)

30 kW 102400 N/A 42° (75°)

35 kW 119400 N/A 42° (75°)

Figure 9: Connecting duct (part # FJADB)

165 mm

(6 1/2")

432 mm (17")

432 mm (17")

305 mm

(12")

460 mm

(18")

blower (not used)

aux. limit

140° F

damper

motor

wood

thermostat

oil or gas

thermostat

wire supplied by

customer

wire supplied with

harness

*

*

jumper

removed

to

blower

motor

110 V

source

24 V

source

common

from 24 V

transformer

low voltage

terminal block

black

white

green

16/3

LVT

16 /2

LVT

14 /2

BX

limit

blower

limit

Figure 8: Wiring diagram for adding on to oil or gas (control kit #FEFC2)

blower and wood

limit - 250°F

to furnace

start relay

Loading...

Loading...