HELPLINE NO 08448012949

8

ORIGINAL INSTRUCTIONS

Fig.E

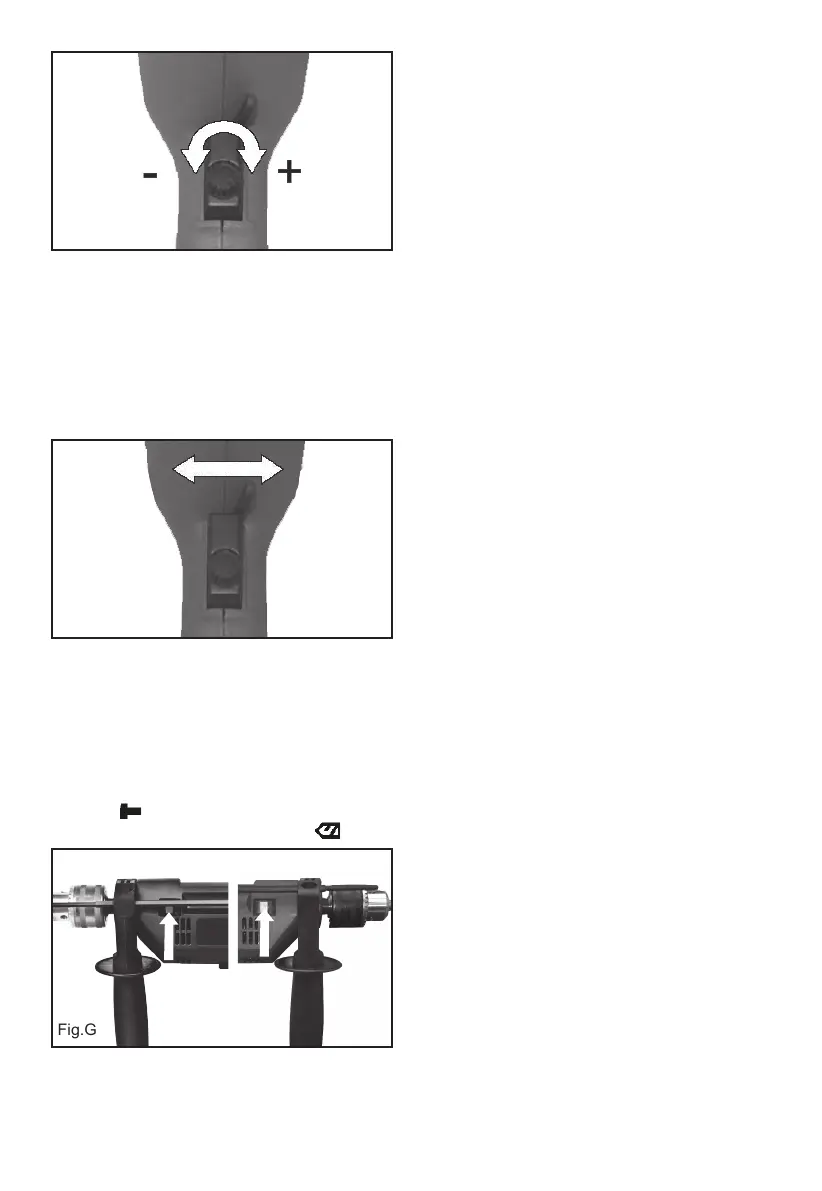

6. CHANGING ROTATIONAL DIRECTION

(See Fig. F)

To change the rotational direction, push the

forward/reverse selector switch to the “R” position

indicated on your drill. The rotation will now

be forward rotation. Push the forward/reverse

selector switch to “L” position indicated on your

drill. The rotation will be reverse rotation.

Fig.F

Reverse rotation

(L)

Forward rotation

(R)

NOTE: Never change the forward/reverse

switch whilst the drill in operation or the on/

off switch is locked.

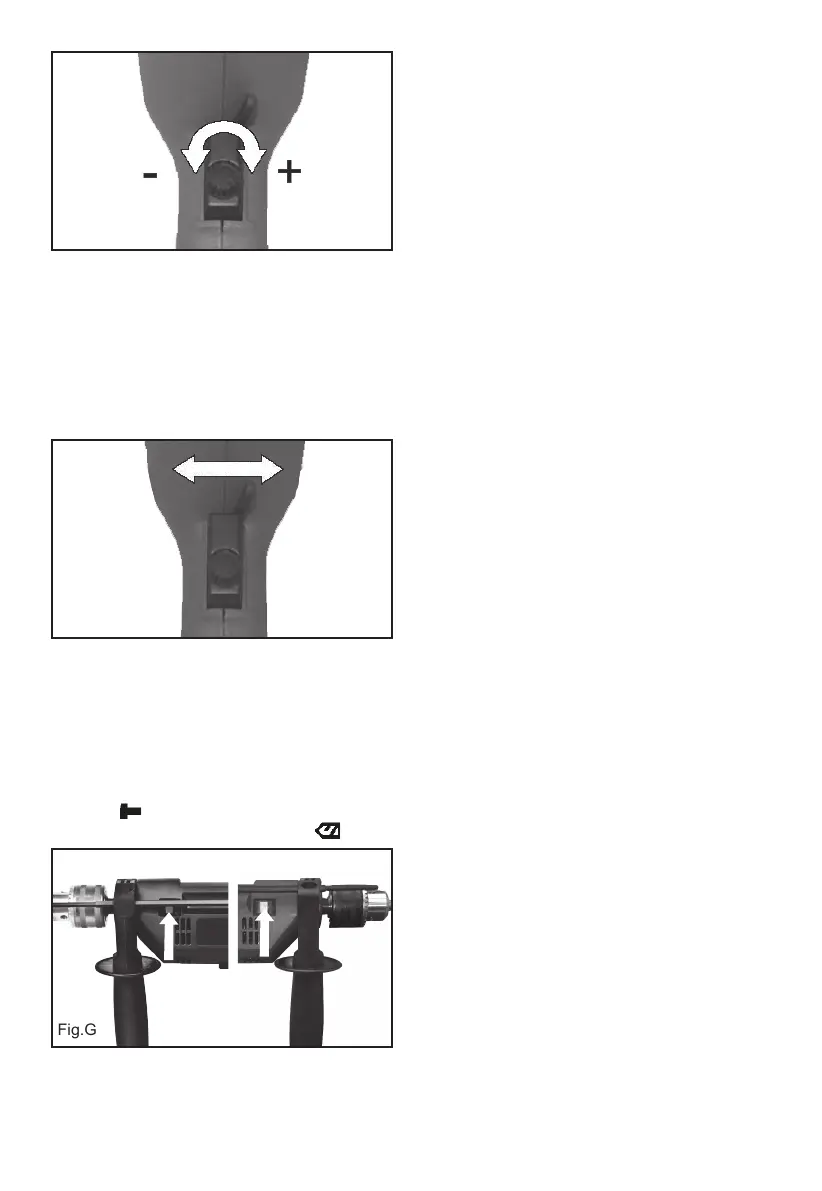

7. DRILL/IMPACT ACTION SWITCH

(See Fig. G)

When drilling masonry and concrete push the

drill/impact action selector switch into the hammer

position “ ”. When drilling wood, metal, plastic

push the switch into the drill position “ ”.

Fig.G

Hammer Drill

WORKING HINTS FOR YOUR

IMPACT DRILL

1. DRILLING MASONRY AND CONCRETE

Select the drill/impact action selector switch to the

“hammer symbol” position. Tungsten carbide drill

bits should always be used for drilling masonry,

concrete etc with a high speed.

2. DRILLING STEEL

Select the drill/impact action selector switch to

the “drill symbol” position. HSS drill bits should

always be used for drilling steel with a lower

speed.

3. SCREW DRIVING

Select the drill/impact action selector switch to the

“drill symbol” position. Use a low speed to drive in

or remove screws.

4. PILOT HOLES

When drilling a large hole in tough material (i.e.

steel), we recommend drilling a small pilot hole

rst before using a large drill bit.

5. DRILLING TILES

Select the drill/impact action selector switch to the

“drill symbol” position to drill the tile. When tile has

been penetrated, switch over to “hammer symbol”

position.

6. COOL THE MOTOR

If your power tool becomes too hot, set the speed

to maximum and run no load for 2-3 minutes to

cool the motor.

MAINTENANCE

1. Your power tool requires no additional

lubrication or maintenance. There are no user

serviceable parts in your power tool.

2. Never use water or chemical cleaners to clean

your power tool. Wipe clean with a dry cloth.

3. Always store your power tool in a dry place.

4. Keep the motor ventilation slots clean.

5. If you see some sparks ashing in the

ventilation slots, this is normal and will not

damage your power tool.

6. If the supply cord of this power tool is

damaged, it must be replaced by a specially

prepared cord available through the service

organization.

Loading...

Loading...