12

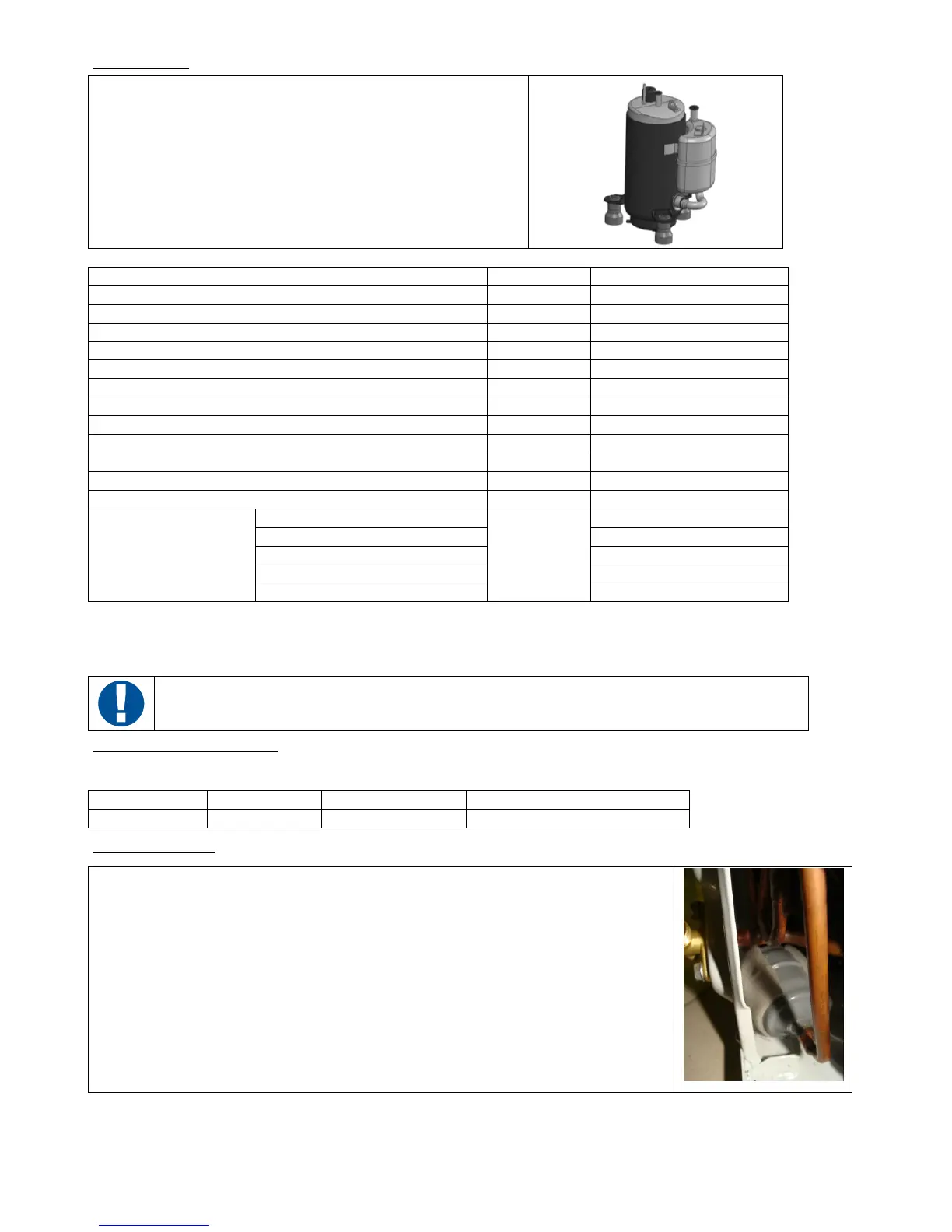

Compressor (*)

Inhales the gas from the evaporator and compresses it in the

condenser. Because of the job of compression, the vapor goes out of

the compressor with more pressure and strongly overheated.

Maintain the conditions of operation of the compressor within the

parameters brought in chart, if not respected, not only the

performances won't be optimal, but it could present malfunctions and

shortening of the life of the compressor.

Characteristic Unit Value

Compressor type - Rotary piston

N° motor poles Nr 2

displacement cm³ 12,2

Start condenser µF/V 15/400

Motor resistance Ω Main 5,84/Aux 7,62

Max quantity of refrigerant R-134a (CH2FCF3) kg 0,9

Oil NE032/L22E or equivalents ml 270 ±20

Mass (oil included) kg 9,2

Power supply 1ph. 220-240V 50Hz

Power consumption W 475/490

Current consumption A 2,3

Heating capacity W 1965/1980

Temperature conditions

Evaporation

°C

10

Condensation 55

Inlet gas 20

Ambient 35,0

Liquid 46,7

The followings conditions are considered possible cause of risks:

• In the case of high or low tension with high ambient temperature (ex. 43°C)

• Return of fluid in liquid phase in the compressor.

• Filling of the filter dehydrator.

Pipe stress: the copper pipeline in outlet of the compressor is subject to vibrations. To avoid breakups, the

constructor applies an insulating material that limits the oscillations (damper), make sure it is entire and is

not altered during maintenance/operations.

Compressor start-up capacitor

The march capacitor has the purpose to start the compressor.

Capacity (μF) Tension (V) Freq (Hz) Terminals

15 ± 5% 450 50/60 Faston 6.3mm

Dehydrator filter (*)

The filter has two functions:

1 - absorbs the contaminants of the circuit as water and acid,

2 - makes a physical filtering.

The ability to remove the water from the circuit is the principal function of the filter.

Loading...

Loading...