Do you have a question about the Armstrong Design Envelope 4322 and is the answer not in the manual?

Safety, ambient temperature, enclosure rating, storage, warranty, uncrating, and handling guidelines.

Location, installation, pump piping, and alignment for proper setup and operation.

Electrical safety, grounding, start/stop, motor protection, and thermal derating guidelines.

Detailed electrical specs for DEPM, Frame 71, and DEPM 2 motors, including inputs/outputs and standards.

Power wiring, tools, disassembly, and terminal wiring for various motor types.

Wiring diagrams for DEPC: battery, Ethernet, CAN bus, RS-485, and networking options.

Modbus register map for firmware v1.16 and older. Covers status, I/O, units, and counters.

BACnet objects for firmware v1.16 and older. Covers status, counters, control settings, and I/O.

Modbus register map for firmware v1.17 and newer. Covers status, I/O, units, and counters.

BACnet objects for firmware v1.17 and newer. Covers status, counters, control settings, and I/O.

Pre-operation checks for pump priming, rotation, lubrication, voltage, and system cleanliness.

Procedures for safely starting and stopping the pump, including priming and discharge valve operation.

Navigation and interaction with the pump's touch screen interface for various functions.

Accessing and using the pump's web interface via Ethernet or Wi-Fi for configuration and monitoring.

Tolerance values for flow and head readings between test stand instrumentation and controller readout.

Motor maximum sound pressure levels (dBA) for various pump models and HP ratings.

Configures the pump to maintain a constant flow rate as system head varies.

Configures the pump to maintain a constant head as system demand varies.

Controls pump speed based on a linear relationship between flow and head.

Controls pump speed based on a quadratic curve between max and min flow for energy efficiency.

Maintains minimum flow for equipment stability, adjusting speed as system load changes.

Limits flow to save energy and ensure system stability, often used for oversized pumps.

Combines minimum and maximum flow protection with quadratic curve control for optimal pump usage.

Manages multiple pumps in parallel for optimal energy usage, staging them based on flow requirements.

Configuration for split units with 100% flow redundancy for superior customer value and reliability.

Alternates lead-pump operation to equalize run hours for Tango, dualARM, and Twin units.

Achieves constant pressure by setting Design Head and Zero Flow Head to the same value.

Configures different flow and head settings for two distinct seasons or operating conditions.

Adds dP sensors to single or parallel pumping systems for enhanced control via LCD or Webserver.

Controls bypass valve operation to protect flow-sensitive equipment based on flow setpoints.

Routine inspection and cleaning of the pump unit to ensure years of trouble-free operation.

Lubrication requirements for pump and motor components, following manufacturer recommendations.

Information on mechanical seal operation, flush lines, and handling precautions for proper function.

Step-by-step guide for replacing the mechanical seal in rigid split-coupled units.

Step-by-step guide for replacing the mechanical seal in close-coupled units.

Importance of cleaning, flushing, and draining the system before pump startup to prevent damage.

List of alarms, their descriptions, and recommended actions for VSD and communication issues.

List of warnings, their descriptions, and recommended actions for VSD, communication, and battery issues.

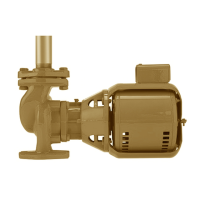

| Brand | Armstrong |

|---|---|

| Model | Design Envelope 4322 |

| Category | Water Pump |

| Language | English |