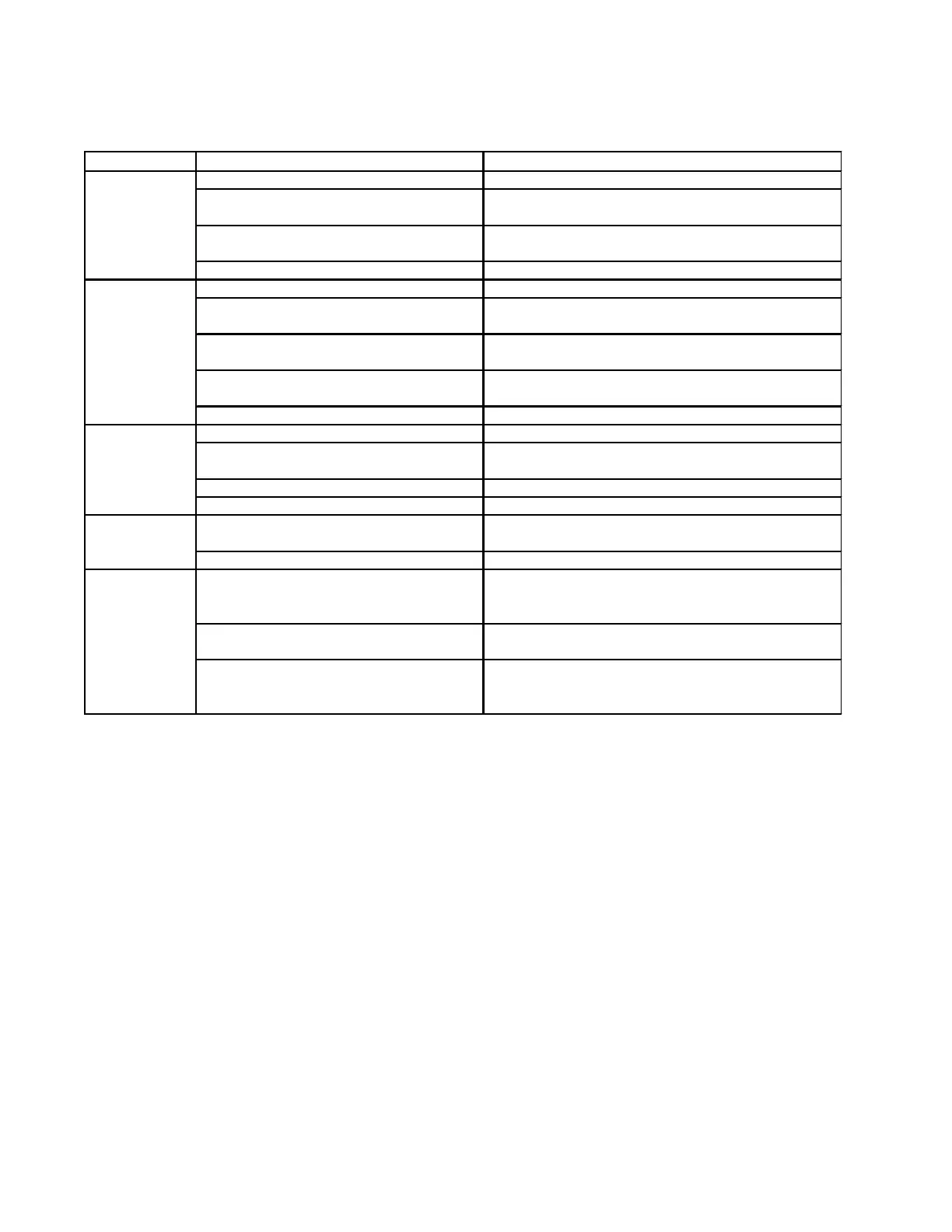

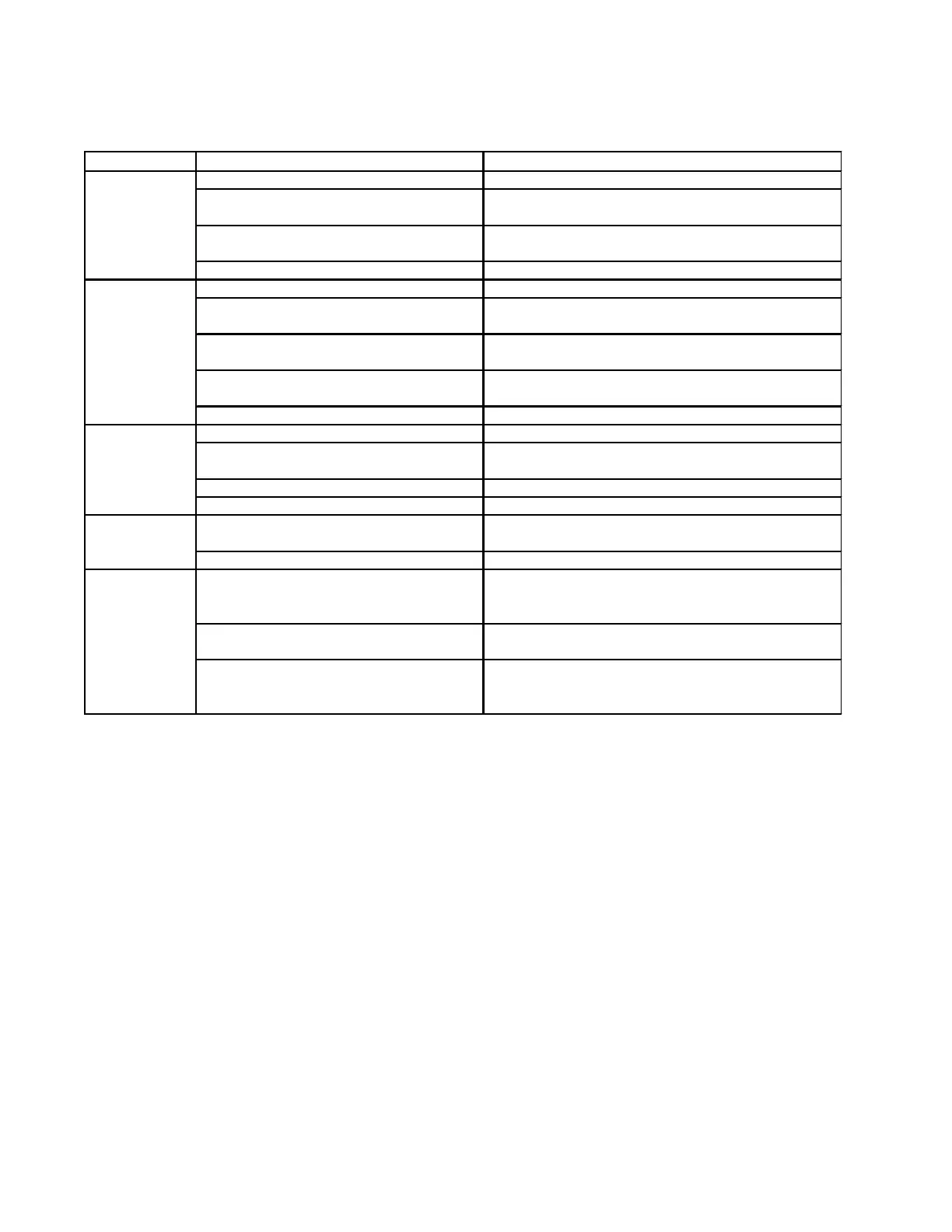

14

TROUBLESHOOTING GUIDE

Table 14-1

DISASSEMBLY

Control Valve - All maintenance on the valve should be done by a factory trained product specialist

with the exception of replacing the pressure sensing diaphragm. To replace the diaphragm remove all nuts and

bolts from the bottom cover. After removing the bottom cover, remove the lock nuts from the bottom of the

valve shaft. You will need to hold the platter to prevent the assembly from spinning, or hold the stem with

large a slotted screw driver in the slot at the bottom of the stem. After removing the nuts, slide the platter off,

then the old diaphragm, being careful not to lose the brass washer above the diaphragm. To reassemble follow

the reverse order. Make sure when tightening the cover bolts that you use a criss-cross pattern.

Problem Causes Solutions

The steam is not turned on to the unit. Open steam valve to the unit.

The water tubes in the heat exchanger are

plugged.

See Clean-In-Place operating instructions or remove

tube bundle and clean.

The differential pressure sensing diaphragm

is ruptured.

Replace the diaphragm.

The mixing valve is not properly adjusted. Adjust the unit according to the instructions.

The steam pressure is too low. Increase steam pressure (2 - 15 psig).

Air has accumulated in the shell of the heat

exchanger.

Install a thermostatic air vent on the shell.

The flow is above the rated capacity of the

unit.

Make sure unit is sized properly.

The tubes in the heat exchanger are scaled.

See Clean-In-Place operating instructions or remove

tube bundle and clean.

The mixing valve is not properly adjusted. Adjust the unit according to the instructions.

The steam pressure is too high. Decrease steam pressure (2 - 15 psig).

Recirculated water is continually diverting

through the Flo-Rite-Temp.

Check diverting valve for a stuck or failed thermal

capsule.

The steam is superheated. Pipe to saturated steam.

The mixing valve is not properly adjusted. Adjust the unit according to the instructions.

The inlet valve on the water supply is closed. Open valve.

There is no demand for hot water. Wait till demand is present then re-check.

The shell of the heat exchanger is not

properly drained.

Make sure steam trap is working and properly installed.

Make sure shell is level to floor. Do not elevate

condensate if pressure is low.

The steam pressure has dropped or a

vacuum has formed.

Increase pressure and install vacuum breaker at shell

drain (Figure 1-1).

The water pressure had dropped below that

of the steam pressure and steam is forming

inside of the water tubes.

Install a pressure switch on water inlet to shut off steam

on a drop in water pressure.

The unit

hammers and

bangs during

operation.

Only cold water

comes out of

the unit.

Only warm

water comes

out of the unit.

Extreme hot

water comes

out of the unit.

No water

comes out of

the unit.

Loading...

Loading...