DW 950 / 951 / 952 / 95C

WATER SOFTENING

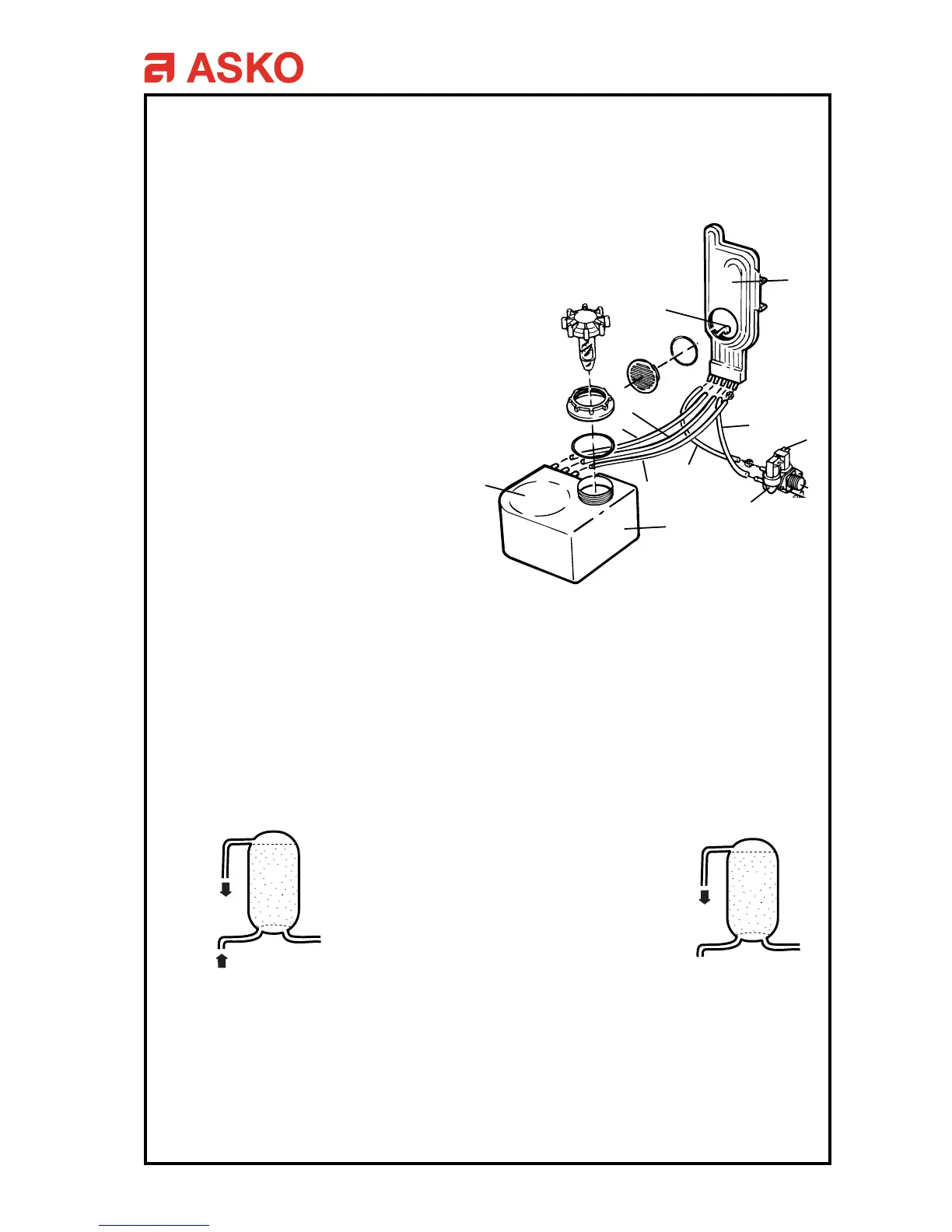

The water softener operates as follows:

During rinse, pre-wash and main wash:

1. Inlet valve 1 opens and admits water.

2. The water flows

• through hose 3 to air-brek device, no 1

• passes an airgap

• leaves the air-break device through no. 3

• passes hose 7 to the resin container of the softe-

ner, no 3.

There the water is softened and the soft water flows

• out through no. 4

• through hose 8 back to the air-break device no. 4

• enters the machine through no. 6.

1 Inlet valve 1

2. Inlet valve 2 (regener ation valve)

3. Hose IV1 - air-break device

4. Hose IV2 - air-break device

5. Air-break device

6. Inlet opening

7. Hose air-break device no. 3- resin

container no. 3

8. Hose air-break device no. 4 – resin

container no. 4

9. Hose air-break device no. 5 - salt

container no. 5

10. Salt container

11. Resin container

Hard water, containing lime,

Ca(HCO

3

)

2

flows into the resin

container. The Ca ions are

replaced by Na. Soft water,

containing Na(HCO

3

) flows

into the machine.

Regeneration during the main wash:

3. When the machine has admitted water, as described above, for the main wash, inlet

valve 2 opens for 20,30 or 50 seconds, depending on the setting. The water flows

through hose 4 to the air-break device 5, on through hose 9 and into salt container no. 5.

The salt-saturated water flows into the resin container, where it regenerates the resin, so

that it can soften further water.

Ca

Na(HCO )

3

Na

Ca(HCO )

3

2

Resin container

1

3

4

2

5

7

8

6

9

10

11

Loading...

Loading...