0

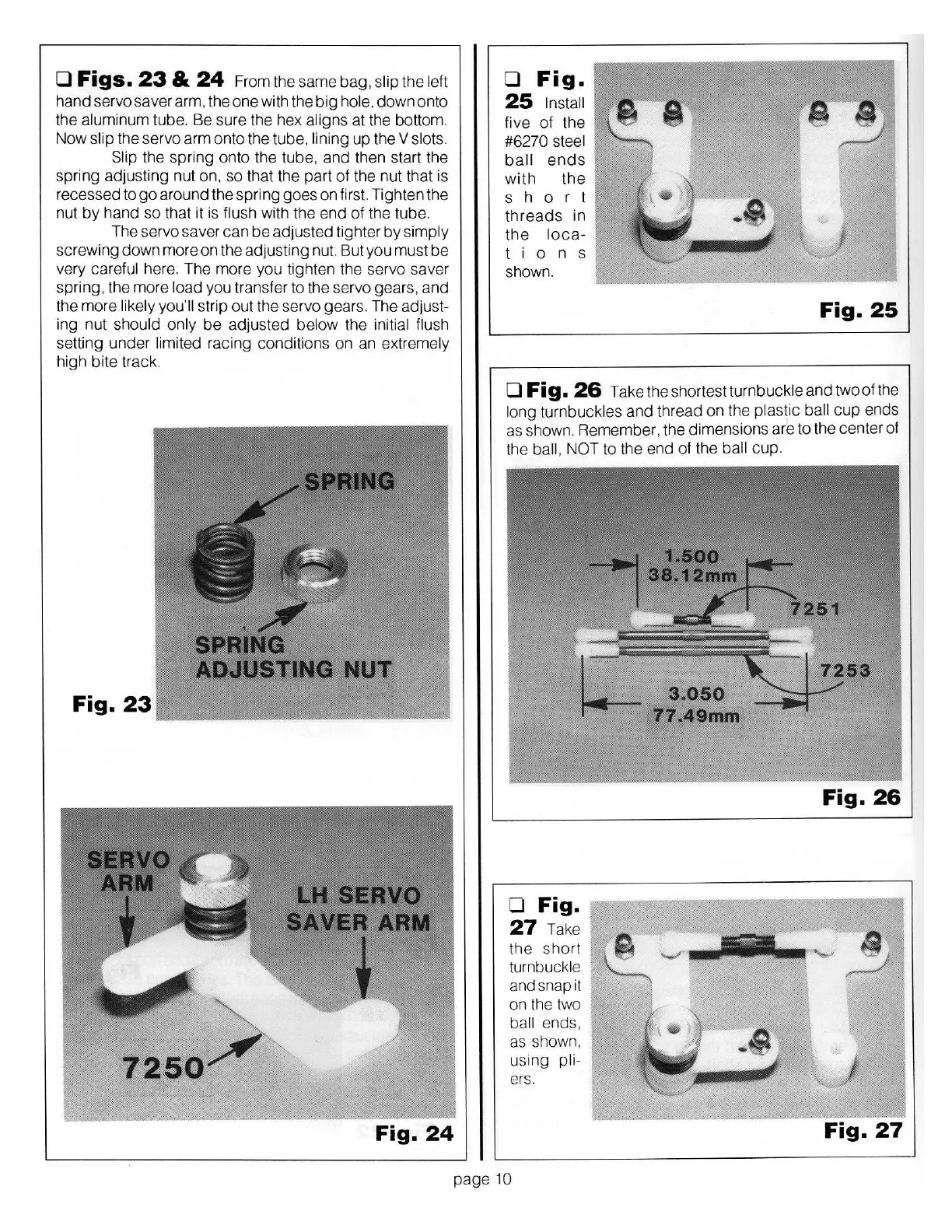

Figs.

23

&

24

From the same bag,

slip

the

left

hand servo saver arm, the one with the

big

hole,

down

onto

the

aluminum

tube. Be sure the hex aligns

at

the bottom.

Now

slip

the servo

arm

onto the tube, lining

up

the

V slots.

Slip

the spring onto the tube, and then start the

spring adjusting nut on,

so

that the part

of

the nut that is

recessed

togo

around the

sp

ring goes on first. Tighten the

nut

by

hand

so

that it is

flush

with the end

of

the tube.

The servo saver

can

be

adjusted tighter

by

simply

screwing

down

more

on

the adjusting nut. But you must

be

very careful

here. The more you tighten the servo

saver

sp

ring, the more

l

oad

you transfer to the servo gears, and

the more likely you'll

strip out the servo gears. The adjust-

ing nut

should only

be

adjusted

below

the initial flush

se

tting

un

der

limited

racing

cond

itions on an

extremely

high bite track.

Fig.

24

0

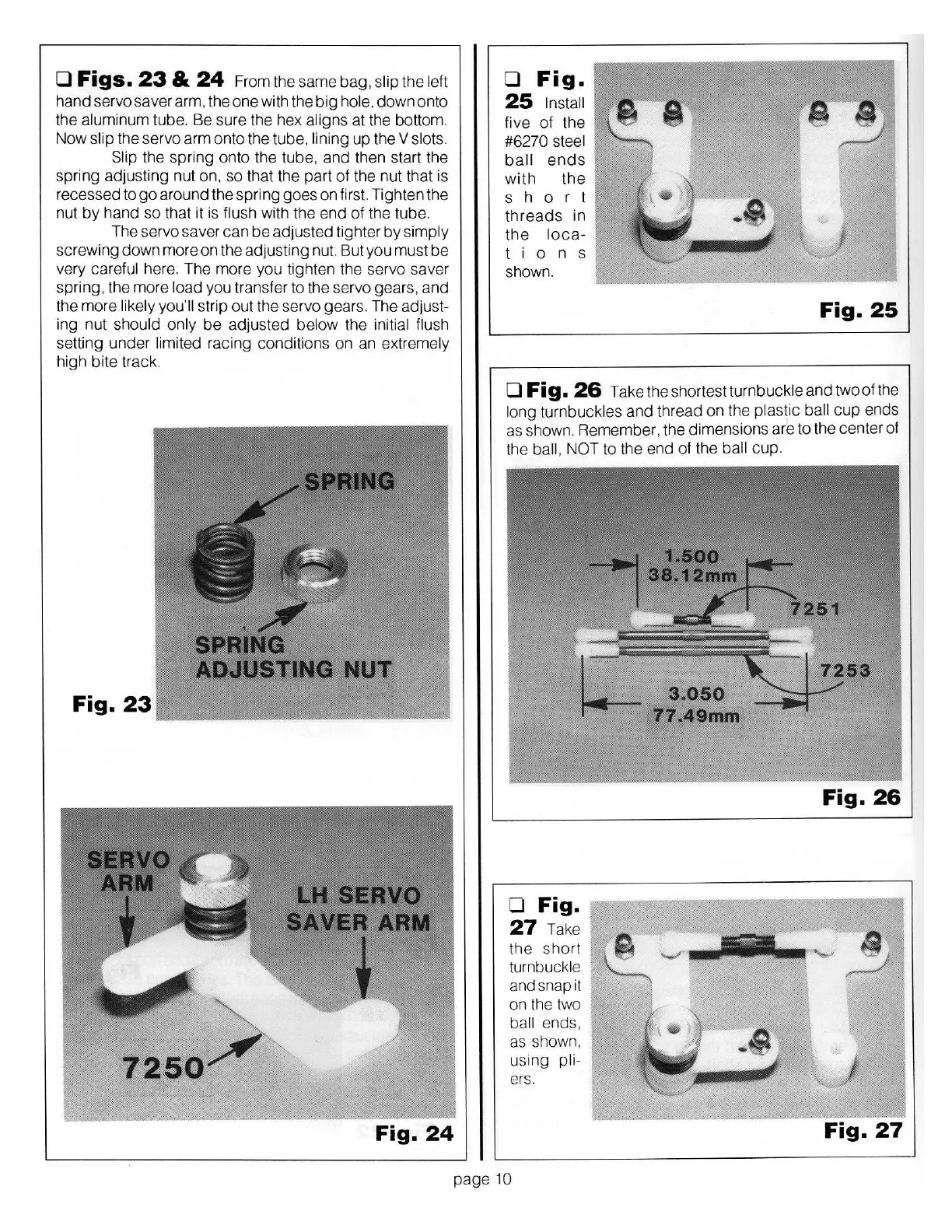

Fig.

25

Install

five

of

the

#6270

steel

ball

ends

with

the

s

h

o r

t

threads

in

the

loca-

l

i

o n s

shown.

Fig.

25

0

Fig.

26

Take the shortestturnbuckle

and

two

of

the

long turnbuckl

es

and thread on the

plastic ball

cup

ends

as shown. Reme

mber

, the dimensions are to the center of

the ball, NOT

to the end

of

the

ball

c

up

.

D

Fig.

27

Take

the

sho

rt

turnbuckle

and snap it

on the two

ball

ends,

as shown,

using

pli-

ers.

Fig.

26

Fig.

27

page

10

Loading...

Loading...