49 | P a g e

118 Description: Flow and return probe plausibility checks failed.

Cause: Incorrect flow and return sensor readings, usually where the flow and returns are reversed.

1. Check system design and alter as required.

2. Use customer information menu or parameter 8.3 to check flow and return temperatures.

3. Check T1 & T2 sensor readings as per the table on page 67. Replace as required.

4. Check harness and connectors are ok, using multimeter to confirm continuity. Replace harness as required.

5. If the above checks are ok, replace the PCB.

140 Description: Working pressure test error 2 times (pump kick)

Cause: No pressure increase while the pump is running at full load for 5 seconds. This can be caused by air in the

boiler, a blocked or faulty pressure sensor or a faulty pump. The pressure increase by the pump must be at least 0.1

bar.

This will only happen if the pump flow control is turned off via parameter 2.9.2. The pressure increase by the

pump must be at least 0.1 bar. Turning the flow control back on can aid fault finding or use the guide below.

1. Check analogue and digital pressure readouts match.

• If these do not match add pressure to the system and check digital gauge reads new pressure.

• Clean sensor if contaminated or replace as required.

2. Use a multimeter to check the wiring harness to the water pressure sensor for continuity from PCB

connector CN12, pins 6, 7 & 8, whilst checking connectors are tight and free from damage or corrosion.

• Replace as required.

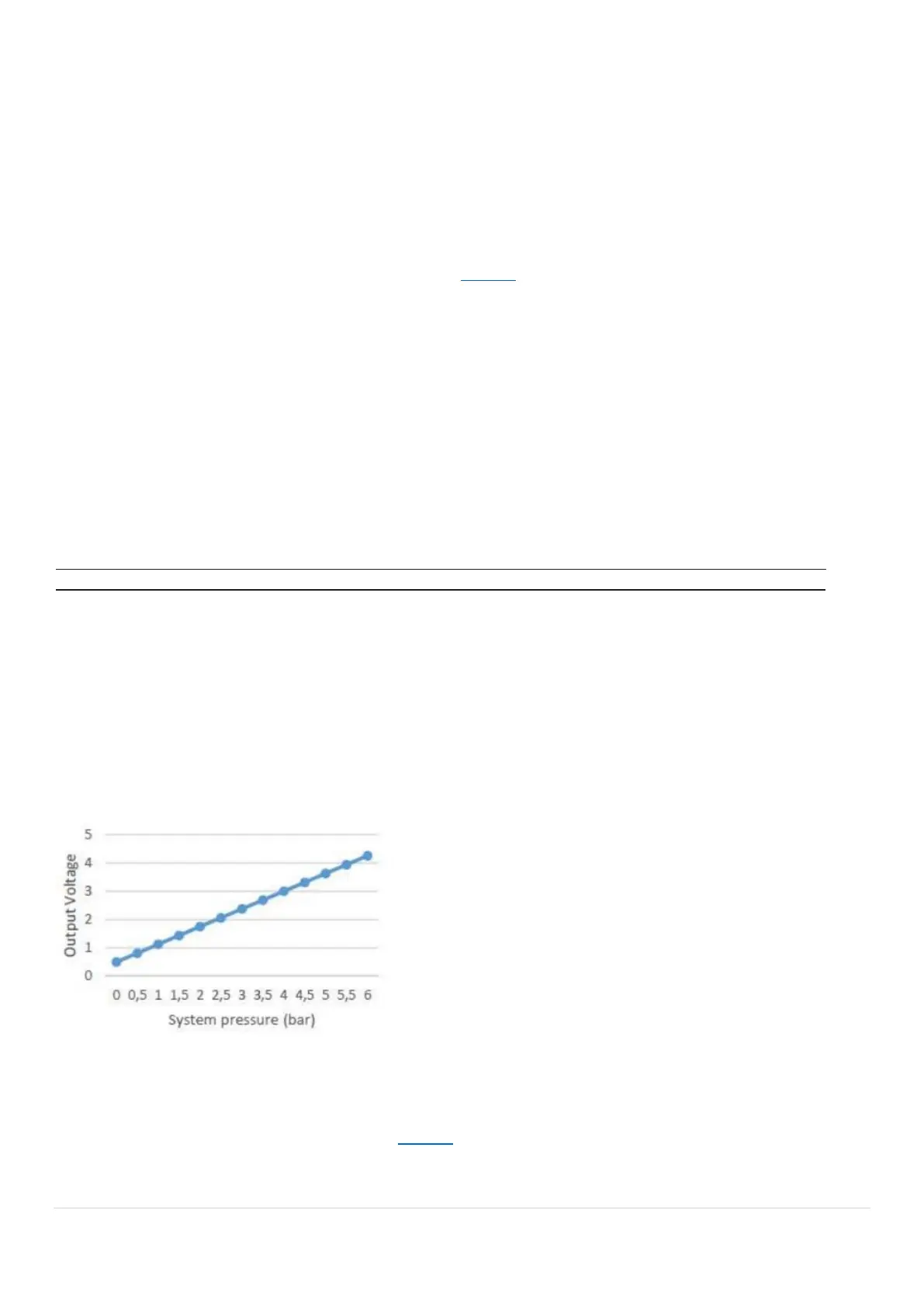

3. Check DC voltage from pressure sensor back to the PCB on connector CN12, pins 7&8. The voltage should be

as per the table below. Clean or replace the sensor as required.

4. Check the pump for air and vent the system if required.

• Use the boiler air purge to assist by turning off the power at the fused spur for 5 seconds and then

re-establish the power.

5. Check auto air vent is operating correctly and not contaminated with sludge.

6. Use pump LEDs for indication of issue on page 66 and action as required.

7. Check the pump is running. Diagnosis can be aided by turning flow control back on & using the customer

information menu to check the pump PWM % and the pump flow rate.

Loading...

Loading...